VR6 engine

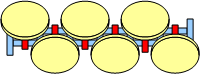

The VR6 engine is an internal combustion engine whose arrangement consists of six cylinders at a narrower angle than usual. It was developed by Volkswagen in the late 1980s.

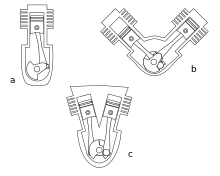

Similar to a V-engine, but with the two mounts offset and sitting next to each other at an angle of 10.6º or 15°, instead of the more common 45°, 60°, or 90° found in conventional V-engines.

Description

The configuration can also be described as a "staggered six-cylinder", in keeping with the staggered four-cylinder geometry of the Lancia Fulvia, which was developed in the late 1950s, a continuation of Lancia design practice dating back to the 1920s. Staggered engines are conducive to improving their design, with an odd number of cylinders and staggered V configurations.

The name VR6 derives from the combination of a V-engine and the German word "Reihenmotor," meaning "in-line engine".

The VR6 was specifically designed for transversely-mounted engines in front-wheel drive cars. By using a narrow 15° angle between the banks in a VR6, it is possible to fit a six-cylinder engine into the four-cylinder engine bay of existing Volkswagen cars. A conventional V6 engine may require lengthening the vehicles to make room for the new, wider engine. The VR6 can utilize the firing order of a straight-six engine, resulting in equally smooth operation.

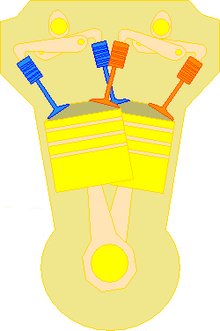

The narrow angle between the cylinders allows only one cylinder bank and one head to be used, whereas conventional V-engines require two separate cylinder banks and two heads. Using only one cylinder head allows the use of two camshafts, instead of four overhead (DOHC) to command all the valves. This simplifies engine construction and reduces costs. On early 12-valve VR6s there were two overhead camshafts with six cams each. The front overhead cam had three intake and three exhaust cams to control the three front cylinders. The rear camshaft was designed in the same way, but it controlled the remaining three cylinders. The principle of operation is similar to the design of an overhead camshaft (SOHC). Later 24-valve VR6s keep the double overhead camshaft, but with 12 cams each. However, the operation of the camshafts on 24-valve engines differs from that of early 12-valve engines, with one cam operating only the exhaust valves and the other the intake valves. This principle is more similar to the double overhead cam design.

There are different variants of the VR6, where the original displaced 2,792 cm³ (2.8 L) and had a two-valve-per-cylinder design (12 total). These delivered a power of 174 PS (172 HP; 128 kW) and a maximum torque of 240 N m (177 lb ft).

Detailed specifications

The original VR6 has a one-piece cast iron crankcase and cylinder blocks and a lightweight cross-flow cylinder head of aluminum alloys, with two valves per cylinder, operated by overhead camshafts commanded by chains. Fuel and ignition are controlled by a Bosch Motronic engine control unit (ECU). This system uses an air flow sensor, a double knock sensor to regulate the ignition of the cylinders, and a lambda probe to regulate the air/fuel mixture. Exhaust gases are channeled through a three-way catalytic converter..

Volkswagen identifies the original VR6 with the code "AAA", which operates on a four-stroke cycle, has a displacement of 2,792 cm³ (2.8 L), although some European engines displace 2,861 cm³ (2.9 L), whose variant is identified with the code “ABV”. The cylinder bore is 81 mm (3.19 in) and the piston stroke is 90 mm (3.54 in). The angle between benches is 15°, with a compression ratio of 10.0:1.

The forged steel crankshaft has six journals for the connecting rods and is supported by seven main bearings. Two overhead camshafts operate hydraulic tappets which, in turn, open and close the valves, 39 mm (1.54 in) for the intake and 34.3 mm (1.35 in) for the exhaust. Because the two "rows" of pistons and cylinders share a single cylinder head and a single gasket, the piston head is slanted. Because of this, the piston wall has a variable height, which leads to uneven heat stress and a heavier piston. The intake and exhaust valves need different camshafts to vary the valve crossover, which can be coaxial, as in some 90° V8s. To minimize the number of camshafts, both rows of cylinders share their camshafts. Due to the geometry, the mid-valves are very long, which can be a problem at high rpm, when used in racing cars. The intake and exhaust ports run very close to the cylinder heads; this heats the incoming air/fuel mixture before it is ignited by the spark plug, which has the effect of reducing power. This also cools the exhaust gases, making it more difficult for the catalytic converter to function. On production road car engines, only one exhaust manifold is used and therefore half of the ducts are very long, increasing the heat inside it, necessitating that it be heavier, doing so with the manifold as well. of admission. Because the cylinder field is greatly reduced compared to the straight-six, the longer ports are formed by ducts of rectangular section rather than the more desirable elliptical or crescent. In road cars, the intake and exhaust ports are usually curved and the different lengths can be easily compensated for.

Due to the cylinder layout in the VR6, with two rows of combustion chambers in the same cylinder head, the intake ducts on the two rows of cylinders are of different lengths. Depending on the specific generation of VR6, this difference in lengths is compensated for in the intake manifold, valve crossover, cam profile, or a combination of these. On the original VR6, each duct has a length of 420 mm (16.5 inches). The exhaust gases are evacuated through a three-arm cast iron exhaust manifold, one dedicated to three cylinders, inside a Y-shaped duct. From this point, the gases are conducted through a duct simple to the catalytic converter, after passing through the Lambda probe.

The fuel injectors, operated by the Bosch Motronic engine control unit (ECU), are mounted behind the intake manifold elbow. The water pump housing is integrated into the cylinder block. The VR6 engine also uses an auxiliary electric pump to circulate engine coolant while the engine is running, in addition to the main pump driven by a timing belt.

A replaceable oil filter is used. The oil pump is mounted on the crankcase and is driven by an intermediate shaft. An oil pressure control valve is built into the pump.

The one-piece cylinder block and crankcase is constructed of pearlitic gray cast iron with micro-alloy steel. The two banks of three cylinders are arranged at an angle of 15º with respect to the crankshaft. The cylinder liners are 81 mm (3.19 in) in diameter, with 65 mm (2.56 in) of cylinder spacing. They are staggered but overlapped across the block, allowing it to be shorter and more compact than a conventional V6.

The center line of the cylinders is offset from the center line of the crankshaft by 12.5 mm (0.49 in). To accommodate the offset cylinders and narrow "V" design, the connecting rod journals are offset 22° from each other. This also allows for a 120° cylinder firing interval. The firing order is 1-5-3-6-2-4.

History and evolution

Volkswagen's VR6 was introduced in Europe in 1991, in the Volkswagen Passat and Corrado; and in North America the following year. The American Passat, Passat Variant, and Corrado used the original 2,792 cm³ (2.8 L) design; the European Corrado and four-wheel drive Passat Syncro was fitted with the 2,861 cm³ (2.9 L) version with 190 PS (187 HP; 140 kW). This version also had a 6 cm (2.4 in) free-flow catalytic converter, thinner camshafts, 4 bar (56.9 psi; 392 kPa) fuel pressure regulator and enlarged intake manifold.

The 2861 cm³ (2.9 L), like the one intended for the Corrado, was originally equipped with a variable length manifold called the "VSR" (Variables SaugRohr, in German) and manufactured by Pierburg for Volkswagen Motorsport. This gave higher torque at low revs, but was dropped due to cost, and instead was offered as an option. This design was later sold to Schrick, who redesigned it and offered it as the Schrick VGI ('Variable Geometry Intake').

In 1992, with the introduction of the Volkswagen Golf III, a six-cylinder was available for the first time in a small-medium segment car in Europe. In North America it was not introduced until 1994; by this time, the European model began using the 2,861 cm³ (2.9 L) in the VR6 Syncro model. The corresponding Volkswagen Vento/Jetta VR6 versions appeared the same year.

Volkswagen removed one cylinder from the VR6 in 1997 to create the VR5 or simply "V5", the first block to use an odd number of cylinders in a V-shaped layout, different of the triple Honda V3 of the famous MotoGP. This version, with a displacement of 2,324 cm³ (2.3 L), delivered 150 PS (148 HP; 110 kW) and a maximum torque of 210 N⋅m (155 lb⋅ft). It was introduced with the Passat in 1997 and the Golf and Bora in 1999.

In 1999, VW added modifications to the design with the introduction of the 2792 cm³ (2.8 L) 24-valve VR6. This delivers 204 PS (201 HP; 150 kW) and 265 N m (195 lb ft) of peak torque. The new version was not available in the Passat, as it was incompatible with the installation scheme used by the generation of engines at the time, but it was introduced in the higher-end Golf and Bora in the European market. The 4WD system, currently called 4motion, became standard on the VR6 in Europe. The corresponding multi-valve V5 was only released in 2001, with power increased by 20 PS (14.7 kW) to 170 PS (168 HP; 125 kW). The multi-valve VR6 was introduced in North America in 2001 in the T4 Eurovan, producing 204 PS (201 HP; 150 kW) and in the GTI in 2002, where it retained the VR6 name.

In 1999, VW also released an updated version of the VR6 12-valve for the North American market for the product line, based on the A4 platform: Golf IV, GTI and Jetta. This new VR6 improved performance with an updated overhead cam, variable length intake manifold, 10.5:1 compression, and improved emissions control kit. Power increased to 177 PS (175 HP; 130 kW) at 5,800 rpm, while peak torque increased to 245 N⋅m (181 lb⋅ft) at 3,200 rpm. It was available from 1999 until 2002, when it was replaced by the 24-valve.

In 2001, the VR6 was enlarged to 3,189 cm³ (3.2 L) to create a limited high-performance version with 228 PS (225 HP; 168 kW) or for the New Beetle, called the Beetle RSi. This VR6 was later used in the Golf IV R32 and also in the original Audi TT. According to Volkswagen, this variant produced 250 PS (247 PS; 184 kW) and 320 N⋅m (236 lb⋅ft) of peak torque in the TT configuration and 241 PS (238 PS; 177 kW) in the R32. Although it was rated at the same power as the European version, the North American version of the R32 featured the larger air mass sensor from the Audi TT, 76 mm (2.99 in) in diameter, versus 70 mm (2. 76 inches) and a different airbox, which gave the same power as the Audi with 250 PS (247 HP; 184 kW).

The 3,189 cm³ (3.2 L) was used at the top of the range in the original Audi A3 and TT. It continued in use in the R32 and the revamped Golf V R32.

In 2005, the European version of the sixth-generation Volkswagen Passat, with a transverse engine, went on sale with a revised 3,189 cm³ (3.2 L) VR6 as its larger option. For the North American market, the Passat received a new 3,598 cm³ (3.6 L) VR6 with a narrower angle of 10.6 degrees, producing 280 PS (276 HP; 206 kW). These 3,189 to 3,598 cm³ (3.2 to 3.6 L) versions featured direct injection of the FSI type, the former developing 250 PS (247 hp; 184 kW) at 6,250 rpm and 330 N m (243 lb ft) at 3000 rpm. The introduction of the Passat VR6 also marked the first time that a vehicle with this type of powertrain had been available in North America before Europe.

The new Passat R36, available since early 2008, received an updated version of the VR6 3.6 FSI with 300 PS (296 HP; 221 kW) at 6600 rpm and 350 N m (258 lb ft) at 2400 rpm, four wheel drive "4motion" standard and Direct-Shift Gearbox (DSG) standard.

The future of VR6

When Volkswagen launched its VR6 in the Passat, the Corrado in 1991 and the Golf GTI in 1992, it was a sign that the brand was moving up a notch. With its narrow 15-degree cylinder angle, the mix of the "V-6 / and an inline-6 engine" was designed specifically for front-wheel drive vehicles, where it would be mounted transversely.

The VR6 brought strong results and silky-smooth power delivery to the compact vehicle segments. Today, with straight-four engines capable of over 300 PS (296 HP; 221 kW), there isn't much of a reason for six-cylinders, and certainly not in compact cars.

In the North American market it was offered in the Passat, Passat CC, Touareg, and entry-level Porsche Cayenne, but it appears its days are numbered.

Though it's not quite finished yet for the VR6, China gets a stripped-down variant of the 3.0-liter and VW has conceptualized a hybrid version. However, in the long run engines with more than four cylinders may be confined to larger longitudinally mounted Volkswagen Group cars.

Uses

2,792 cm³ (2.8 L; 170.4 in³)

It has a bore x stroke of 81 x 90.3 mm (3.19 x 3.56 in). With a compression ratio of 10.0:1 it produces a power of 174 PS (172 HP; 128 kW) @ 5800-6000 rpm and a maximum torque of 235 to 240 N m (173 to 177 lb ft) @ 4200 rpm.

- Applications

- Volkswagen Passat B4

- VW Golf GTI

- Volkswagen Vento

- Ford Galaxy

- Mercedes-Benz Vito

With the compression ratio increased to 10.5:1 it produces 178 PS (176 HP; 131 kW) @ 5800 rpm and 240 N m (177 lb ft) @ 4200 rpm of torque.

- Applications

- Volkswagen Corrado

Another version increases its power to 196 PS (193 HP; 144 kW) @ 6000 rpm and 280 N m (207 lb ft) @ 3200 rpm of torque.

- Applications

- Volkswagen Passat B4

Another option went up to 200 PS (197 HP; 147 kW) @ 6200 rpm and 265 N m (195 lb ft) @ 3200 rpm of torque.

- Applications

- Volkswagen Jetta 2004

Another was increased to 204 PS (201 HP; 150 kW) @ 6200 rpm and 245 to 270 N m (181 to 199 lb ft) @ 2500-3200 rpm of torque.

- Applications

- Volkswagen Bora

- Volkswagen Sharan

- SEAT León Cupra 4

- VW Multivan 2.8 V6

- SEAT Alhambra

2,861 cm³ (2.9 L; 174.6 in³)

It has a bore x stroke of 82 x 90.3 mm (3.23 x 3.56 in), which with a compression ratio of 10.0:1 produces 184 PS (181 HP; 135 kW) @ 5800 rpm and 245 N m (181 lb ft) @ 4200 rpm max torque.

- Applications

- Volkswagen Passat Variant VR6 Syncro

Another option was rated at 190 PS (187 HP; 140 kW) @ 5800 rpm and 245 N m (181 lb ft) @ 4200 rpm of torque.

- Applications

- Volkswagen Corrado

- Volkswagen Golf VR6 Syncro

3,189 cm³ (3.2 L; 194.6 in³)

It has a bore x stroke of 84 x 95.9 mm (3.31 x 3.78 in) and with a compression ratio of 11.3:1, it produces 219 HP (222 PS; 163 kW) @ 5800 rpm and 305 N m (225 lb ft) @ 3200 rpm torque.

- Applications

- Volkswagen Touareg

With a compression ratio of 10.0:1, it is boosted to 224 PS (221 HP; 165 kW) @ 6200 rpm and 320 N m (236 lb ft) @ 3000 rpm of torque.

- Applications

- Volkswagen New Beetle RSi

With a compression ratio of 11.3:1, it is boosted to 241 PS (238 HP; 177 kW) @ 6250 rpm and 315 to 320 N m (232 to 236 lb ft) @ 2400-2800 rpm of torque.

- Applications

- VW Golf R32

- Volkswagen Phaeton

With a compression ratio of 10.9:1, it is boosted to 250 PS (247 HP; 184 kW) @ 6300 rpm and 310 to 320 N m (229 to 236 lb ft) @ 2500-5500 rpm of torque.

- Applications

- Volkswagen Eos

- VW Golf R32 DSG

- Audi A3 3.2 V6 quattro DSG

- Audi TT

- Porsche Cayenne

3,598 cm³ (3.6 L; 219.6 in³)

It has a bore x stroke of 89 x 96.4 mm (3.50 x 3.80 in) which with FSI direct injection and a compression ratio of 11.4:1, produces 260 HP (264 PS; 194 kW) @ 6000 rpm and 350 N m (258 lb ft) @ 2500-5000 rpm of torque.

- Applications

- Škoda Superb (B6, 3T)

Another version has been boosted to 280 HP (284 PS; 209 kW) @ 6200 rpm and 350 N m (258 lb ft) @ 2500 rpm of torque.

- Applications

- Volkswagen Passat NMS

- Volkswagen Passat B8

- Audi Q7

Another version has been boosted to 300 HP (304 PS; 224 kW) @ 6300-6600 rpm and 350 to 400 N m (258 to 295 lb ft) @ 2400-5300 rpm of peak torque.

- Applications

- Volkswagen Passat CC 3.6 FSI

- Porsche Cayenne

- Artega GT

Other applications of VR technology

The Volkswagen Group has developed a series of engines that use the "narrow angle" of 72 degrees, for example: two imaginary VR6s are coupled at a 72 degree angle resulting in a W12 configuration, which is much shorter than a conventional V12 engine, being slightly wider. For the W8 and W16 designs developed with a similar shape, the W8 uses what would be two VR four-cylinders, while the W16 uses two bank of eights, each in a VR arrangement, in keeping with the staggered inline VR geometry..

VR5

The VR5 engine has been used in the following vehicles:

- Volkswagen Golf IV

- Volkswagen Bora

- Volkswagen Passat B5

- Volkswagen New Beetle

- SEAT Toledo Mk2

Contenido relacionado

Aeromodelling

Diode

Obsolescence