Solid

The solid (from the Latin solĭdus) is a state of aggregation of matter, which is characterized by resisting changes in shape and volume. Its particles are close together and also look correctly ordered. The molecules of a solid have great cohesion and take on well-defined shapes. There are several disciplines that study solids:

- The physics of the solid state experimentally and theoretically studies the condensed matter, that is, of liquids and solids containing more than 1019 atoms in contact with each other.

- Deformable solid mechanics study microscopic properties from the perspective of continuous media mechanics such as tension, deformation and thermodynamic magnitudes and ignore the internal atomic structure because for certain types of problems this is not relevant.

- Materials science deals primarily with solids' properties as phase structure and transformations.

- Solid state chemistry specializes in the synthesis of new materials.

Keeping the pressure constant at low temperature, the bodies appear in solid form and are intertwined, generally forming crystalline structures. This gives the body the ability to withstand forces without apparent deformation.

The lightest known solid is a man-made material, airgel with a density of 3 mg/cm³ or 3 kg/m³, glass, which has a density of 1.9 g/cm³, while the densest is a metal, osmium (Os), which has a density of 22.6 g/cm³.

Microscopic description

The atoms, molecules, or ions that make up solids can be arranged in an ordered repeating pattern, or irregularly. Materials whose constituents are arranged in a regular pattern are known as crystals. In some cases, the regular ordering can continue uninterrupted on a large scale, for example diamonds, where each diamond is a Single Crystal. Solid objects that are large enough to see and handle are rarely made of a single crystal, but instead are made up of large numbers of individual crystals, known as crystallites, that can range in size from a few nanometers to several meters. These types of materials are called polycrystals. Almost all common metals, and many ceramics, are polycrystalline.

In other materials, there is no long-range order in the position of atoms. These solids are called amorphous solids; some examples are polystyrene and glass.

Whether a solid is crystalline or amorphous depends on the material in question and the conditions under which it was formed. Solids that are formed by slow cooling tend to be crystalline, whereas solids that are quickly frozen are more likely to be amorphous. Likewise, the specific crystalline structure that a crystalline solid assumes depends on the material in question and how it was formed.

While many common objects, like an ice cube or a coin, are chemically identical throughout, many other common materials are made up of a number of different substances packed together. For example, a typical rock is an aggregate of several different minerals and mineraloids, without a specific chemical composition. Wood is a natural organic material made up mainly of cellulose fibers embedded in an organic lignin matrix. In materials science, composites of more than one constituent material can be designed to have desired properties.

Properties of a solid

- Elasticity: A solid recovers its original form when deformed. A resort is an object in which we can observe this property as it returns to its original form.

- Fragility: A solid can break in many fragments (bradizo).

- Hardness: Hardness is the opposition that the materials offer to alterations such as penetration, abrasion, scratching, cutting, and permanent deformations among others. The diamond is a solid with high hardness.

- Defined form: They have defined form, are relatively rigid and do not flow as gases and liquids do, except under extreme pressures of the medium.

- High density: Solids have relatively high densities due to the proximity of their molecules so they are said to be more “weighted”

- Floating: Some solids meet this property, only if its density is less than that of the liquid in which it is placed.

- Inertia: it is the difficulty or resistance that opposes a physical system or a social system to possible changes, in the case of solids it resists changing their state of rest.

- Tenacity: In Materials science tenacity is the resistance that opposes a material to spread fissures or cracks.

- Suitability: It is the property of matter, which present the bodies to be carved by deformation. Inadequacy allows the collection of thin sheets of material without breaking, in common having no method to quantify them.

- Ductility: The ductility refers to the property of the solids to be able to obtain threads from them.

- Rigidity: Some solids can resist more than others the bends and twists.

- Deformation: Some solids can deform without breaking, acquiring a different form than they had.

- Alleability: Property that has the materials to form alloys that give rise to new materials improving their benefits.

- Specific heat: The heat capacity of a substance is the energy needed to increase 1 °C its temperature

Classes of solids

Forces between atoms in a solid can take many forms. For example, a crystal of sodium chloride (common salt) is made up of sodium and chlorine ions, which are held together by ionic bonds. In diamond or silicon, atoms share electrons and form covalent bonds. In in metals, electrons are shared in metallic bonding. Some solids, particularly most organic compounds, are held together by van der Waals force resulting from the polarization of the electronic charge cloud in each molecule. The dissimilarities between the types of solids result from the differences between their bonds.

Metals

Metals are usually strong, dense, and good conductors of both electricity and heat. Most of the elements on the periodic table, those to the left of a diagonal line from boron to polonium, are metals. Mixtures of two or more elements in which the main component is a metal are known as alloys.

Since prehistoric times, man has used metals for various purposes. The strength and reliability of metals has led to their widespread use in the construction of buildings and other structures, as well as in most vehicles, many appliances and tools, pipes, traffic signals, and railroads. Iron and aluminum are the two most commonly used structural metals. They are also the most abundant metals in the Earth's crust. Iron is mainly used in the form of an alloy, steel, which contains up to 2.1% carbon, making it much harder than pure iron.

Because metals are good conductors of electricity, they are valuable in electrical appliances and for carrying an electrical current over long distances with little loss or dissipation of energy. Thus, electrical networks are based on metal cables to distribute electricity. Domestic electrical systems, for example, are wired with copper for its good conductive properties and easy machinability. The high thermal conductivity of most metals also makes them useful for cookware.

The study of metallic elements and their alloys is an important part of the fields of solid-state chemistry, physics, materials science, and engineering.

Metallic solids are held together by a high density of shared and delocalized electrons, known as "metallic bonding". In a metal, atoms easily lose their outermost ("valence") electrons, forming positive ions. The free electrons are distributed throughout the solid, which is held together firmly by the electrostatic interactions between the ions and the electron cloud. The large number of free electrons gives metals their high values of electrical and thermal conductivity. The free electrons also prevent the transmission of visible light, making metals dull, shiny, and lustrous.

The most advanced models of the properties of metals consider the effect of positive ion nuclei on delocalized electrons. Since most metals have a crystalline structure, these ions are usually arranged in a periodic lattice. Mathematically, the potential of ionic nuclei can be treated by several models, the simplest being the quasi-free electron model.

Minerals

Minerals are naturally occurring solids formed through various geological processes under high pressures. To be classified as a true mineral, a substance must have a crystalline structure with uniform physical properties throughout. The composition of minerals varies from pure elements and simple salts to highly complex silicates with thousands of known forms. Instead, a rock sample is a random aggregate of minerals and/or mineraloids, and does not have a specific chemical composition. The vast majority of the rocks of the earth's crust are made up of quartz (crystalline SiO2), feldspar, mica, chlorite, kaolin, calcite, epidote, olivine, augite, hornblende, magnetite, hematite, limonite and some other minerals. Some minerals, such as quartz, mica, or feldspar, are common, while others have only been found in a few places in the world. By far the largest group of minerals is the silicates (most rocks are ≥95% silicates), which are largely composed of silicon and oxygen, with the addition of aluminum, magnesium, iron, calcium and other metals.

Ceramics

Ceramic solids are made up of inorganic compounds, usually oxides of chemical elements. They are chemically inert, and are often able to withstand chemical weathering that occurs in an acidic or caustic environment. Ceramic materials can generally withstand high temperatures ranging from 1,000 to 1,600 °C (1,800 to 3,000 °F). The exceptions are non-oxidized inorganic materials such as nitrides, borides, and carbides.

Traditional ceramic raw materials include clay minerals such as kaolinite; among the most recent materials is aluminum oxide (alumina). Modern ceramic materials, classified as advanced ceramics, include silicon carbide and tungsten carbide. Both are valued for their resistance to abrasion, which is why they are used in applications such as wear plates on crushing equipment in mining operations.

Most ceramic materials, such as alumina and its compounds, are formed from fine powders, giving rise to a fine-grained polycrystalline that is filled with light scattering centers comparable to the wavelength of visible light. Therefore, they are usually opaque materials, as opposed to transparent materials. However, recent nanoscale technology (eg sol-gel) has made it possible to produce transparent polycrystalline ceramics, such as transparent alumina and alumina compounds, for applications such as high power lasers. Advanced ceramics are also used in medicine and in the electrical and electronics industry.

Technical Ceramics is the science and technology of creating solid-state ceramic materials, parts, and devices. This is done either by the action of heat or, at lower temperatures, using precipitation reactions from chemical solutions. The term includes the purification of raw materials, the study and production of the corresponding chemical compounds, their formation into components, and the study of their structure, composition, and properties.

From a mechanical point of view, ceramic materials are brittle, hard, strong in compression and weak in shear and tension. Brittle materials can exhibit significant tensile strength when supporting a static load. Toughness indicates how much energy a material can absorb before failing mechanically, while fracture toughness (denoted KIc) describes the ability of a material with inherent microstructural defects to resist fracture through growth. and crack propagation. If a material has a large fracture strength value, basic principles of fracture mechanics suggest that it is most likely to undergo ductile fracture. Brittle fracture is very characteristic of most ceramic and glass-ceramic materials that tend to have low (and inconsistent) KIc values.

As an example of ceramic applications, the extreme hardness of zirconia is used in the manufacture of knife blades, as well as other industrial cutting tools. Ceramics such as alumina, boron carbide, and silicon carbide have been used in bulletproof vests to repel large-bore rifle fire. Silicon nitride parts are used in ceramic ball bearings, where their high hardness makes them resistant to wear. In general, ceramics are also chemically resistant and can be used in humid environments where steel bearings would be susceptible to oxidation (or rust).

As another example of ceramic applications, in the early 1980s, Toyota investigated the production of an adiabatic ceramic motor with an operating temperature of more than 6,000 °F (3,300 °C). Ceramic engines do not need a cooling system and therefore allow a significant reduction in weight and, consequently, greater fuel efficiency. In a conventional metal engine, much of the energy released by the fuel must be dissipated as waste heat to prevent metal parts from melting. Work is also underway on the development of ceramic parts for gas turbine engines. Ceramic turbine engines could run more efficiently, giving planes greater range and payload for a given amount of fuel. However, these motors are not manufactured because manufacturing ceramic parts with sufficient precision and durability is difficult and expensive. Processing methods often result in a wide distribution of microscopic defects that often play a detrimental role in the sintering process, leading to crack proliferation and eventual mechanical failure.

Cooktop

Glass-ceramic materials share many properties with both non-crystalline glasses and with crystalline materials and ceramic materials. They form as a glass and are then partially crystallized by heat treatment, producing both amorphous and crystalline phases, such that the crystalline grains are embedded within a non-crystalline intergranular phase.

Glass ceramics are used to make cookware, originally known by the brand name CorningWare, and cooktops that have both high resistance to thermal shock and extremely low permeability to liquids. The negative coefficient of thermal expansion of the crystalline ceramic phase can be balanced by the positive coefficient of the glassy phase. At a given point (~70% crystalline) the glass-ceramic has a net coefficient of thermal expansion close to zero. This type of glass ceramic has excellent mechanical properties and can withstand repeated and rapid temperature changes of up to 1000°C.

Glass ceramics can also be produced naturally when lightning strikes crystalline grains (eg, quartz) found in most beach sand. In this case, the immediate extreme heat of lightning (~2500 °C) creates hollow, branching root-like structures called fulgurite through melting.

Organic solids

Organic chemistry studies the structure, properties, composition, reactions, and preparation by synthesis (or other means) of the chemical compounds of carbon and hydrogen, which may contain any other elements such as nitrogen, oxygen, and the halogens: fluorine, chlorine, bromine and iodine. Some organic compounds may also contain the elements phosphorus or sulfur. Some examples of organic solids are wood, paraffin wax, naphthalene, and a wide variety of polymers and plastics.

Wood

Wood is a natural organic material made up mainly of cellulose fibers embedded in a lignin matrix. Regarding the mechanical properties, the fibers are strong in tension, and the lignin matrix resists compression. For this reason, wood has been an important construction material since humans began building shelters and using boats. Timber used for construction is commonly known as timber or wooden. In construction, wood is not only a structural material, but is also used to form the concrete mould.

Wood-derived materials are also widely used for packaging (for example, cardboard) and paper, which are created from the refined pulp. Chemical pulping processes use a combination of high temperature and alkaline (kraft) or acid (sulfite) chemicals to break the chemical bonds of the lignin before burning it.

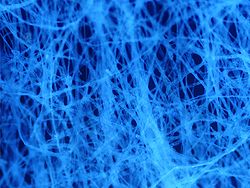

Polymers

An important property of carbon in organic chemistry is that it can form certain compounds, the individual molecules of which are able to bond together, thus forming a chain or network. The process is called polymerization and the chains or networks, polymers, while the parent compound is a monomer. There are two main groups of polymers: those made artificially are called industrial polymers or synthetic polymers (plastics) and those of natural origin as biopolymers.

Monomers can have various chemical substituents, or functional groups, that can affect the chemical properties of organic compounds, such as solubility and chemical reactivity, as well as physical properties, such as hardness, density, mechanical or tensile strength, abrasion resistance, heat resistance, transparency, color, etc. In proteins, these differences give the polymer the ability to adopt one biologically active conformation in preference to others (see self-assembly).

Man has used natural organic polymers for centuries in the form of waxes and shellac, which is classified as a thermoplastic polymer. A plant polymer called cellulose provided the tensile strength of natural fibers and ropes, and in the early 19th century natural rubber it was in widespread use. Polymers are the raw materials (resins) used to make what are commonly called plastics. Plastics are the final product, created after one or more polymers or additives have been added to a resin during processing, which is given a final shape. Polymers that have existed and are in widespread use today include polyethylene, polypropylene, polyvinyl chloride, polystyrene, nylons, polyester, acrylics, polyurethane and polycarbonate, and silicone-based silicone. Plastics are generally classified into "basic", "special" and "engineering".

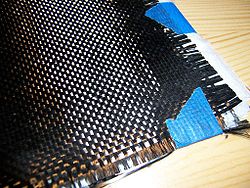

Composite material

Composites contain two or more macroscopic phases, one of which is usually ceramic. For example, a continuous matrix and a dispersed phase of ceramic particles or fibers.

Applications for composite materials range from structural elements such as steel-reinforced concrete to thermal tiles that play a key and integral role in the NASA Space Shuttle thermal protection system, which is used to protect the surface of the shuttle from the heat of reentry into the Earth's atmosphere. One example is Reinforced Carbon (RCC), the light gray material that withstands reentry temperatures up to 1,510 °C (2,750 °F) and protects the nose cap and leading edges of the space shuttle's wings. RCC is a laminated composite material made of rayon graphite and impregnated with a phenolic resin. After high temperature curing in an autoclave, the laminate is pyrrolyzed to convert the resin to carbon, impregnated with furfural alcohol in a vacuum chamber, and cured/pyrrolyzed to convert the furfural alcohol to carbon. In order to provide oxidation resistance for reusability, the outer layers of the RCC are converted to silicon carbide.

Domestic examples of composite materials can be seen in the plastic casings of televisions, mobile phones, etc. These plastic cases are usually a composite made up of a thermoplastic matrix such as acrylonitrile butadiene styrene (ABS) to which calcium carbonate chalk, talc, glass fibers or carbon fibers have been added to give it strength, bulk or electrostatic dispersion.. These additions may be called reinforcing or dispersing fibers, depending on their purpose.

Thus, the matrix material surrounds and supports the reinforcing materials, maintaining their relative positions. The reinforcements impart their special mechanical and physical properties to enhance the properties of the matrix. The synergy produces material properties not available in the individual constituent materials, while the wide variety of matrix and reinforcement materials provides the designer with the choice of an optimal combination.

Semiconductors

Semiconductors are materials that have an electrical resistivity (and conductivity) between that of metallic conductors and that of non-metallic insulators. They are found on the periodic table moving diagonally down to the right of boron. They separate electrical conductors (or metals, on the left) from insulators (on the right).

Devices made of semiconductor materials are the basis of modern electronics, including radio, computers, telephones, etc. Semiconductor devices include the transistor, solar cells, diodes, and integrated circuits. Photovoltaic solar panels are large semiconductor devices that directly convert light into electrical energy.

In a metallic conductor, current is carried by the flow of electrons", but in semiconductors, current can be carried by electrons or by "electron holes" positively charged in the electronic band structure of the material. The most common semiconductor materials are silicon, germanium, and gallium arsenide.

Nanomaterials

Many traditional solids have different properties when reduced to nanometer sizes. For example, gold nanoparticles, normally yellow, and silicon nanoparticles, gray, are red; gold nanoparticles melt at much lower temperatures (~300 °C for a size of 2.5 nm) than gold plates (1064 °C); and metal nanowires are much stronger than the corresponding metals at bulk. The high surface area of nanoparticles makes them very attractive for certain applications in the energy field. For example, platinum metals can provide improvements as automotive fuel catalysts as well as proton exchange membrane (PEM). Ceramic oxides (or cermets) of lanthanum, cerium, manganese, and nickel are also being developed as solid oxide fuel cells (SOFCs). Lithium, lithium-titanate and tantalum nanoparticles are being applied in lithium-ion batteries. Silicon nanoparticles have been shown to dramatically expand the storage capacity of lithium-ion batteries during the expand/contract cycle. Silicon nanowires move without significant degradation and have the potential for use in batteries with greatly extended storage times. Silicon nanoparticles are also being used in new forms of solar power cells. The deposition of silicon quantum dots on the polycrystalline silicon substrate of a photovoltaic (solar) cell increases the voltage by up to 60% by fluorescence of incoming light prior to its capture. Also in this case, the surface of the nanoparticles (and thin films) plays a fundamental role in maximizing the amount of radiation absorbed.

Biomaterials

Many natural (or biological) materials are complex compounds with remarkable mechanical properties. These complex structures, arising from hundreds of millions of years of evolution, are inspiring materials scientists to design new materials. Its defining characteristics are structural hierarchy, multifunctionality, and self-healing capacity. Self-organization is also a fundamental feature of many biological materials and the way structures are assembled from the molecular level. Thus, self-assembly is emerging as a new strategy in the high-throughput chemical synthesis of biomaterials.

Contenido relacionado

Molecule

Particle accelerator

Fire