Screwdriver

A screwdriver (driver or screwdriver) is a tool used to tighten and loosen screws and other machine elements that require little tightening force and are generally small in diameter.

Names

In El Salvador, Honduras, Nicaragua, Mexico, and Guatemala, this tool is also known as a screwdriver. The term screwdriver is also valid, although it is a lesser term. frequent and most used in the American continent.

History

The oldest documented screwdrivers were used in Europe, in the late Middle Ages. They were probably invented in the 15th century, in Germany or France. The original German and French names for the tool were schraubendreher and tournevis, respectively. The earliest known documentation of the tool is found in the Housebook of Wolfegg Castle, a medieval manuscript written between 1475 and 1490.

- Star screwdriver

In 1933, Oregonian J.P. Thompson invented a & # 34; cruciform recessed screw & # 34;, but found no promoters for his proposal. His invention languished until engineer Henry Phillips, who liked the idea, bought the patent rights to Thompson's design. Phillips recognized the advantages of the recessed star or cross shape of the screw head: the screwdriver fit the heads of these screws better than a flat head screwdriver and a slotted screw; it also allowed more torque with less effort. It is also known as a striated screwdriver, mainly in Venezuela.

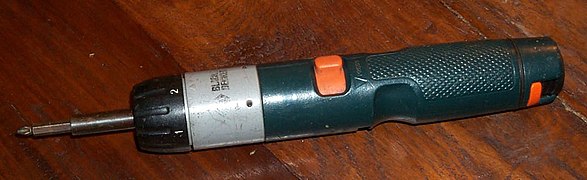

- Electric screwdriver

The electric screwdriver is equipped with a motor, which may be inside the handle. The tip of the screwdriver is usually interchangeable and has accessories to use it with nuts. These screwdrivers decrease labor time and can prevent wrist injuries.

Components

A screwdriver normally consists of three distinct parts:

- Mango: Element to which it is subjected is of an insulating material and in a suitable way to transmit torsion force, in addition to ergonomics to facilitate its use and increase comfort.

- Lobby or rod: Metal bar that binds the tip to the handle. You can have an accommodation where interchangeable tips are placed or have the tip forged and hardened in the same piece. They are often steel for tools, with chromium, vanadium and sometimes also molybdenum. Its diameter and length varies depending on the type of screwdriver.

- Punta: is the part that is inserted into the screw. Depending on the screw type a different type of head will be used, which varies according to the need. There are countless types of screwdriver heads and all for the same purpose. Some of the most frequent types of tips are: flat or shovel, four-pointed star, stretch or cross (Phillips and Pozzidriv) and 6-point star (Torx), as well as the hollow hexagonals (called cup) or macizas (alve Allen) or squares.

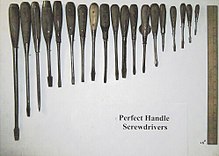

Handle

The handle and shaft of screwdrivers have changed considerably over time. Design is influenced by both purpose and manufacturing requirements. The "Perfect Handle" was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Many manufacturers adopted this handle design. At that time, the 'flat blade' type of screw predominated, which was the fastener with which they were designed to be used. Another popular design was composed of drop-forged steel with riveted wooden handles.

The shape and material of many modern screwdriver handles are designed with ergonomic form factors in mind to fit comfortably in the user's hand to provide maximum control and torque. Designs include indentations for the user's fingers and surfaces made of a soft material such as thermoplastic elastomer to increase comfort and grip. Rigid plastic and rubber composite handles are also common. Many screwdriver handles are not smooth and often not round, but instead have flats or other irregularities to improve grip and prevent the tool from rolling when on a flat surface.

Some screwdrivers have a short hex section at the top of the blade, adjacent to the handle, so a ring wrench or open-end wrench can be used to increase the applied torque. Another option are 'cabinet' screwdrivers, which are made of flat bar and, although the shaft may be rounded, have a large flat section adjacent to the handle on which a (often adjustable) wrench can be used.) for additional leverage. The Offset Screwdriver has a handle positioned at a right angle to the small blade, allowing access into tight spaces and providing additional tightening torque.

Types of screwdriver bits

There are many types of screwdrivers depending on the type of tip, or what is the same, depending on the screw with which they are perfectly adapted to work.

The most common screwdriver bits are:

- Parker, flat or shovel

- Phillips, Star, Stage or Cross (Ph)

- Pozidriv (Pz)

- Hexagonales or allen

- Robertson

- Torx

- Glass or glass

Socket or socket: the tip of this screwdriver is like the hexagonal but inverted, the screw does not have a hole inside but on the outside it has 6 contact points.

Tri-Wing: this is like a triangle but made with straight lines, it has 3 contact points, and it is common to find it in electronics.

Pentalobe: its name comes from the fusion of pentagon and petal, it has 5 rounded contact points. It is exclusively from the Apple brand, that is to say, it is only found in its products.

Grooved

The tool used to insert a slotted head screw is called standard, common blade, flat blade, slot head, straight blade. , flathead, flathead, or "flathead". confusing, because the term flat head also describes a screw with a flat top, designed to be installed in a countersunk hole. Also, the term implies that a screwdriver has a "head"; It is not like this. Such a flat head screw may have a slotted, cross, square or combination head. Before the development of the newer bit types, the flat blade was called the 'common blade', because it was the most common. Depending on the application, the name of this screwdriver may differ. Within the automotive/heavy electrical industries, it is known as a "flathead screwdriver"; within the avionics and mining industries, it is known as a "standard screwdriver". many names; the original 1908 device was known as a "flat head screw.".

Among slotted screwdrivers, variations in blade or tip end involve the profile of the blade seen from the front (from the side of the tool). The most common type is sometimes called keystone, where the profile of the blade is slightly flared before tapering at the end, providing additional rigidity to the work surface and making it capable of withstanding more torque.. To maximize access in space-restricted applications, the sides of the "cabinet" they are straight and parallel, reaching the end of the blade at a right angle. This design is also frequently used in jeweler's screwdrivers.

Many textbooks and vocational schools instruct mechanics to grind the tip of the blade, which, due to the tapered shape, increases its thickness and therefore allows for a more precise engagement with the screw slot. This approach creates a set of graduated slotted drivers that are matched to a particular screw to achieve a tighter fit and reduce screw head deformation. However, many better quality screwdriver blades are already induction tempered (surface heat treated), and polishing the tips after manufacturing compromises their durability. Therefore, it is best to select a tip that is made to fit precisely to start with and avoid weakening from the factory heat treatment.

Phillips

Phillips screwdrivers come in several standard sizes, ranging from tiny "jeweler's to those used to assemble a car frame, or #000 to #4, respectively. This size number is usually stamped on the stem (shaft) or shank for identification. Each bit size accommodates a variety of screw sizes, more or less well. Each Phillips screwdriver size also has a related shank diameter. The driver has a 57° point and conical and blunt (rounded) flutes. The #1 and smaller bits come to a blunt point, but the #2 and larger bits have no point, but rather a nearly square point, making each size incompatible with the other.

The design is often criticized for its tendency to come out at lower torque levels than other 'crosshead' designs, an effect caused by the tapered profile of the flutes which makes them easier to insert into screw than other similar styles. There has long been a popular belief that this was actually a "deliberate" design. Evidence for this specific narrative is lacking, and the feature is not mentioned in the original patents. However, a later refinement of the original design described in US Patent No. 2,474,994 describes this feature.

Robertson

The Robertson screwdriver, also known as the square, or Scrulox screwdriver, has a square-shaped socket on the head of the screw and a square protrusion on the tool. Both the tool and the socket have a conical shape, which makes insertion of the tool easier and also tends to help keep the screw in the tip of the tool without the user needing to hold it there. (The cone's primary raison d'être was to make screw manufacturing practical using cold-formed heads, but its other advantages helped popularize the unit.) Robertson screws are common in Canada, although they have been used elsewhere, and have become much more common in other countries in recent decades. Robertson screwdrivers are easy to use with one hand, because the tapered socket tends to retain the screw, even if it is shaken. They also allow the use of angled screwdrivers and trim head screws. Socket head Robertson screws are self-centering, reduce cam, stop a power tool when tightened, and can be removed if painted or old and rusted. In industry, they speed production and reduce product damage. One of its first major industrial uses was the production of the Ford Motor Company Model A and Model T. Henry Ford found them highly reliable and saved considerable production time, but was unable to license them in the United States, so limited their use to his Canadian division only. Robertson head screwdrivers are available in a standard range of tip sizes from 1.77mm to 4.85mm.

Reed and Prince

Reed and Prince, also called Frearson, is another historic cross head screw configuration. The cross on the head of the screw is sharper and less rounded than a Phillips, and the bit has 45° wings and a sharper, more pointed end. Also, the slot of the Phillips screw is not as deep as the Reed and Prince slot. In theory, different size R&P screws will fit any size R&P bit.

Pozidriv

Pozidriv and the related Supadriv are widely used in Europe and most of the Far East. While Pozidriv screws have cross heads such as Phillips and sometimes, thought to be the same, the Pozidriv design allows for a higher torque application than Phillips. It is often claimed that they can apply more torque than any of the other Phillips screwdriver systems in common use, due to a complex spline (mesh) configuration.

Japanese Industrial Standard (JIS)

Japanese Industrial Standard (JIS) Phillips screwdrivers are still another standard, often incorrectly called "Japanese Phillips". Compatible screw heads are generally identified by a single depressed point or an "X" to one side of the transverse groove. This is a bolt on standard throughout the Asian market and Japanese imports. The driver has a 57° tip with a flat tip.

Other types

Many modern electrical appliances, if they contain screws, use screws with heads that are not the typical slotted or Phillips styles. Torx is one such pattern that has become widespread. It is a knurled point with a corresponding recess in the head of the screw. The main cause of this trend is manufacturing efficiency: Torx screwdriver tips do not slide out of the holder as easily as a Phillips or slotted screwdriver would. (Slotted screws are rarely used in mass-produced devices, since the driver is not inherently centered in the fastener.)

Atypical holders are common in consumer devices for their ability to make disassembly more difficult, which is seen as a benefit to manufacturers, but seen as a disadvantage by users than if more common head types were used. In microwave ovens, these screws prevent casual access to high-power kilovolt electrical components, which are very dangerous.

However, Torx and other drivers are widely available to the consumer due to their increasing use in industry. Some other styles fit a three-pointed star socket and a five-lobed slot with rounded edges instead of the square edges of Torx. This is called a pentalobe.

Specialized patterns of security screws are also used, such as the Line Head (LH) style from OSG System Products, Japan, as used on many Nintendo consoles, although drivers for security screw heads most common security are, again, readily available. Another type of security head has smooth curved surfaces instead of the edges of the slots that would allow the screw to loosen; it is found on privacy screens in public restrooms and cannot be removed with conventional screwdrivers.

Special screwdrivers

Precision screwdrivers are small in size and have a rotating plate at the end of the handle to facilitate handling with one hand. They are used in activities such as watchmaking or others that require working with small screws such as glasses or mobile phones.

A pole finder is a screwdriver with a high reactance lamp built into its handle to check that a conductor is connected to a phase of the alternating current network.

Variations

Torque Screwdrivers

Screwdrivers are available (manual, electric, and pneumatic) with a clutch that slips at a preset torque. This helps the user to tighten the bolts to a specified torque without damaging or over-tightening them. Cordless drills designed to be used as screwdrivers often have such a clutch.

Motorized Screwdrivers

Interchangeable drills allow the use of motorized screwdrivers, commonly using an electric or pneumatic engine to rotate the drill. Wireless drills with speed control and torsion are commonly used as electric screwdrivers.

![]()

Ratchet Screwdrivers

Some hand screwdrivers have a ratcheting action whereby the screwdriver blade locks into the handle to rotate clockwise, but disengages to rotate counterclockwise when pulled. adjusts to tighten screws, and vice versa to loosen.

Spiral ratcheting screwdrivers, often colloquially called the "Yankee screwdriver" (a mark), provide a special mechanism that transforms linear motion into rotational motion. Originally, the name "Yankee" it was used in all tools sold by the North Brothers Manufacturing Company but later, after the company was purchased by Stanley, it became synonymous with only this type of screwdriver. The user pushes the handle into the workpiece, causing a ratchet in a spiral groove to rotate the shank and removable bit. The ratchet can be set to rotate left or right with each press, or it can be locked so the tool can be used like a conventional screwdriver. One drawback to this design is that if the bit comes out of the vise, the resulting sudden extension of the spring can cause the bit to scratch or damage the workpiece.

Once very popular, versions of these spiral ratcheting screwdrivers that use proprietary bits have been largely discontinued by manufacturers like Stanley. Some companies now offer a modernized version that uses standard 1⁄4 inch hex shank power tool bits. Since there are a wide variety of drill bits available in this format, the tool can do double duty as a "push drill" or Persian drill.