Scissors

A scissors, often called in its plural scissors, is a hand tool that is used to cut different types of materials. It is made up of two steel blades that rotate around a common axial screw, with respect to which the cutting edges are located on one side and the handles on the opposite side. The handles have holes for holding and maneuvering with the thumb and finger. The mechanism formed is a typical example of a first-order lever, in which the fulcrum is located between resistance (resistant effort) and power (motor effort). The blades rub against each other in such a way that when they close they leave no space between them, thus cutting the desired object.

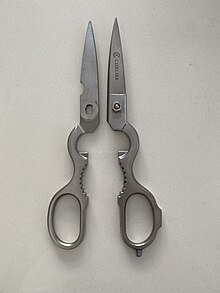

There are several types of scissors, whose design and prototype depends on the specific application for which they are intended, for example in offices, kitchens, sewing, hairdressing, nursing, surgery or gardening, even with several types for every job.

History

The first known scissors appeared in Mesopotamia between 3000 and 4000 years ago. They were of the 'spring scissors' type; which comprised two bronze blades connected at the handles by a thin, flexible strip of curved bronze that served to keep the blades aligned, to allow them to be squeezed together, and to separate them when released.

Spring scissors continued to be used in Europe until the 16th century. However, bronze or iron pivoting scissors, in which the blades pivoted at a point between the tips and the handles, direct ancestors of modern scissors, were invented by the Romans around 100 AD. C. They came into common use not only in ancient Rome, but also in China, Japan and Korea, and the idea is still used in almost all modern scissors.

Early manufacturing

During the Middle Ages and Renaissance, spring scissors were made by heating a bar of iron or steel, then flattening and shaping its ends into blades on an anvil. The center of the bar was heated, bent to form the spring, and then cooled and reheated to make it flexible.

The Hangzhou Zhang Xiaoquan company, in Hangzhou (China), has been manufacturing scissors since 1663.

William Whiteley & Sons (Sheffield) Ltd. produced scissors in 1760, although it is believed that the business began operating even earlier. The first trademark, 332, was granted in 1791. The company continues to manufacture scissors today, and is the oldest company in the West to do so.

Pivoting scissors were not manufactured in large quantities until 1761, when Robert Hinchliffe of Sheffield produced the first pair of modern scissors made of hardened and polished cast steel. His biggest challenge was shaping the arches; First, he made them solid, then he drilled a hole and then filed the metal so that it was large enough to accept the user's fingers. This process was laborious, and Hinchliffe apparently improved it to increase production. Hinchliffe lived in Cheney Square (currently the site of Sheffield Town Hall), and put up a sign identifying himself as a 'maker of fine scissors'. It achieved great sales in London and other places.

During the 19th century, scissors were hand-forged with elaborately decorated handles. They were made by hammering the steel onto serrated surfaces known as "protuberances" to form the leaves. Handle rings, known as bows, were made by drilling a hole in the steel and enlarging it with the pointed end of an anvil.

In 1649, in Sweden, an iron factory was founded in the town of Fiskars, between Helsinki and Turku. In 1830, a new owner started Finland's first cutlery factory, manufacturing, among other items, scissors under the Fiskars brand.

Modern manufacturing regions

China

The vast majority of global scissor manufacturing takes place in China. In 2019, China was responsible for 64.3% of global scissor exports. When combined with exports from Chinese Taipei, this rises to 68.3%. The main scissors producing region in China is located in Guandong Province.

The Zhang Xiaoquan company of Hangzhou, founded in 1663, is one of the oldest scissor manufacturers in the world. The company was nationalized in 1958 and now employs 1,500 people who annually produce an estimated 7 million pairs of economical scissors that retail for an average of $4 each.

France

At the end of the 14th century the English word scissors began to be used. It was derived from the Old French word, "cisoires" which referred to the scissors.

There are several historically important scissor-producing regions in France: Haute-Marne in Nogent-en Bassigny, Châtellereault, Thiers and Rouen. These cities, like many other scissor-producing communities, began with the production of sabers, swords and bayonets, which passed to scissors and other blades at the end of the XVIII century and the beginning of the XIX century.

Thiers, in the Puy-de-Dôme department in Auvergne, remains an important production center for scissors and cutlery. It houses both the Musée de la Coutellerie, which displays the city's 800-year history of knife manufacturing, as well as Coutellia, a sector fair that is advertised as one of the largest annual gatherings of artisanal knife makers in the world.

Germany

Germany was responsible for manufacturing just under 7% of global scissor exports in 2019. Often called 'the city of blades', Solingen, in North Rhine-Westphalia, It has been a center of scissor manufacturing since medieval times. At the end of the 18th century it is estimated that there were more than 300 scissors in Solingen..

In 1995, the city of Solingen passed the Solingen Ordinance, an update of a law from the 1930s that decreed that "Made in Solingen" They could only apply to products manufactured almost entirely in the former industrial area of Solingen. In 2019 this applied to around 150 companies manufacturing high-quality blades of all types, including scissors.

Freidrich Herder, founded in Solingen in 1727, is one of the oldest scissor manufacturers still operating in Germany.

Italy

Premana, in the province of Lecco, has its origins in blacksmithing and knife making from the 16th century. In 1900 there were ten scissor manufacturing workshops, 20 in 1952 and 48 in 1960. Today, the Premax Consortium, an industrial association, organizes more than 60 local companies dedicated to the manufacture of scissors for world markets. In In 2019, Italy exported 3.5% of the scissors manufactured worldwide.

One of the oldest Premanese scissor manufacturing companies still in operation is Sanelli Ambrogio, founded in 1869.

Japan'

The manufacture of scissors in Japan evolved from the manufacture of swords in the 14th century. Seki, in Gifu Prefecture was a renowned center of sword-making beginning in the 1200s. When citizens were no longer allowed to carry katana, the city's blacksmiths turned to making scissors and knives. There are many specialized types of swords. Japanese scissors, but sewing scissors were introduced by American Commodore Matthew Perry from the United States in 1854.

Sasuke's workshop in the city of Sakai, south of Osaka, is run by Yasuhiro Hirakawa, a fifth generation of scissors. The company has been in business since 1867. Yasuhiro Hirakawa is the last traditional scissors manufacturer in Japan, making traditional style scissors in which the blades are believed to be thinner, lighter and sharper than European scissors. In 2018 He was profiled in a documentary that featured a pair of his bonsai scissors that sold for $35,000.

Spain

In Solsona, Spain, the manufacture of scissors began in the 16th century. In the 18th century, when the industry was at its peak, there were 24 workshops, organized as the Guild of Saint Eligius, patron of the knife makers. In the mid-1980s there were only two left, and in 2021, Pallarès Solsona, founded in 1917 by Lluìs and Carles Pallarès Canal, and still family-run, was the only manufacturer of artisanal scissors left in the city.

United Kingdom

Sheffield, York, was the place where scissors were first mass-produced, starting in 1761. In the 19th century it is estimated that there were around 60 steel scissors companies in Sheffield. However, since the 1980s, the globalization of the industry and the shift towards cheaper, mass-produced scissors led to price deflation, with which many artisan manufacturers could not compete. In 2021, the Sheffield scissors industry only had two local companies.

The two remaining scissor makers in Sheffield are William Whiteley, founded in 1760, and Ernest Wright, who was established in 1902. Both now focus on the high-end/niche craftsmanship of "products for all life" rather than mass production. Between these two firms it is estimated that there are no more than ten "Putter-Togetherers" or "Putters" who are the master craftsmen responsible for assembling high quality Sheffield scissors. In 2020, Ernest Wright was recognized with the Crafts in Danger Award by the British Heritage Crafts Association.

Description and operation

A scissors consists of two pivoting blades. In lower quality scissors, the cutting edges are not particularly sharp; It is primarily the shearing action between the two blades that cuts the material. In high-quality scissors, the blades can be extremely sharp and tension spring-loaded, to increase cutting and shear stress only at the exact point where the blades meet. Hand movement (pushing with the thumb, pulling with the fingers) can increase this tension. An ideal example is high-quality tailor's scissors or shears, which should be able to perfectly cut (and not simply tear) delicate fabrics such as chiffon and silk.

Children's scissors are usually not particularly sharp, and the tips of the blades are usually blunt or "rounded" For security.

Mechanically, the scissors are a first class double lever with the pivot acting as a fulcrum. For cutting thick or heavy material, the mechanical advantage of a lever can be taken advantage of by placing the material to be cut as close to the fulcrum as possible. For example, if the force applied (on the handles) is twice as far from the fulcrum as the cutting location (i.e., the point of contact between the blades), the force at the cutting location is twice the force applied to the handles. Scissors cut the material by applying a local shear stress at the cut site that exceeds the shear resistance of the material.

Some scissors have an appendage, called a finger bolster or finger shank, under the hole of the index finger for the middle finger to rest on to provide better control and more power in precision cutting. The finger tang can be found on many quality scissors (even cheap ones) and especially hair cutting scissors (see image of hair scissors below). In the haircut, some claim that the ring finger goes in where some place the index finger, and the little finger rests on the spike of the finger.

For people who do not have use of their hands, there are scissors specially designed to be operated with the foot. Some quadriplegics can use a mouth-operated motorized scissors.

Contenido relacionado

PHP nuke

DirectX

Horizontal and vertical parity

Button (computing)

Commodore 128