Pulley

A pulley is a simple machine, a mechanical traction device, used to transmit a force. It consists of a wheel with a channel on its periphery, through which a rope passes that rotates on a central axis. In addition, forming sets—rigs or hoists—serves to reduce the magnitude of the force needed to move a weight.

According to La Goupillière's definition, "the pulley is the fulcrum of a rope that, while moving, wraps itself around it without making a complete turn" acting at one end of the resistance and at the other the power.

The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991-1802 BCE) and Mesopotamia in the early 2nd millennium BCE. In Roman Egypt, the pulley was identified by Hero of Alexandria (c. 10-70 CE) as one of six simple machines used to lift weights. The pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulleys are also assembled as part of belt and chain transmission to transmit power from one rotating shaft to another. Plutarch's work Parallel Lives recounts a scene in which Archimedes demonstrated the efficacy of compound pulleys and the block and latch system using one of them to pull a fully loaded boat towards it as if it were sliding through the water.

History

The only historical note on its use is due to Plutarch, who in his work Parallel Lives (c. 100 BC) reports that Archimedes, in a letter to King Hiero of Syracuse, who was a great friend of him, affirmed that with a given force he could move any weight and even boasted that if another Earth existed, going to it could move this one. Hiero, astonished, asked Archimedes to perform a demonstration.

They agreed that the object to be moved was a ship from the king's navy, since Hiero believed that it could not be removed from the dock and taken to dry dock without the use of great effort and numerous men. As Plutarch relates, after loading the ship with many passengers and with the holds full, Archimedes sat down at a distance and pulling the rope effortlessly raised the ship, lifting it out of the water as straight and stable as if it were still in the sea.

Pulley parts

It is made up of three parts:

- La llanta: It is an outer zone of the pulley and its constitution is essential, as it will be adapted to the shape of the belt.

- The body: The pulleys are formed by a solid piece when they are small. When their dimensions increase, they will be provided with nerves and/or arms that generate the pulley, joining the bucket with the tire.

- The Cube: It is the conical and cylindrical hole that serves to attach to the axis. Conical couplings in the pulleys are now widely used, as their assembly is very comfortable.

Designation and types

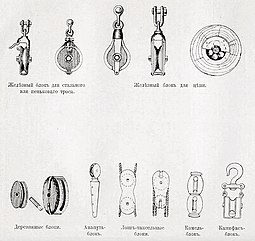

The constituent elements of a pulley are the wheel or pulley itself, on whose circumference (rim) there is usually a groove called a "throat" or "cashier" whose shape conforms to that of the rope in order to guide it; the "arms", armor in the shape of an inverted or rectangular U that completely surrounds it and at whose upper end it mounts a hook by which the assembly is suspended, and the "axle", which It can be fixed if it is attached to the arms with the pulley traversed by it ("eye pulleys"), or mobile if it is attached to the pulley ("shaft pulleys"). When, as part of a transmission system, the pulley rotates freely on its axis, it is called "idle".

According to their displacement, pulleys are classified as "fixed", those whose arms are suspended from a fixed point (the structure of the building) and therefore, do not undergo any translational movement when used with "mobiles", which are those in which one end of the rope is suspended from a fixed point and during its operation they generally move vertically.

When the pulley works independently it is called "simple", while when it is joined with others forming a system it is called "combined" or "compound".

Compound pulleys

There are multiple pulley systems that aim to obtain a great mechanical advantage, that is, to lift large weights with little effort. These pulley systems are diverse, although they have something in common, in any case, they are grouped into groups of fixed and mobile pulleys: the hoists stand out:

Hoists or rigging

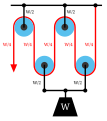

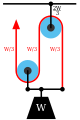

The hoist (from the Latin polyspaston, and this from the Greek πολύσπαστον), is the most common configuration of a compound pulley. In a hoist, the pulleys are distributed in two groups, one fixed and one mobile. An arbitrary number of pulleys is installed in each group. The load is attached to the mobile group.

Rope and pulley systems

A rope and pulley system, that is, a block and tackle, is characterized by the use of a single continuous rope to transmit a tension force around one or more pulleys to lift or move a load; the rope can be a light line or a strong cable. This system is included in the list of simple machines identified by Renaissance scientists.

If the rope and pulley system does not dissipate or store energy, then its mechanical advantage is the number of parts of the rope acting on the load. This can be demonstrated in the following way.

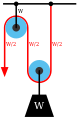

Consider the set of pulleys that make up the moving block and the parts of the rope that support this block. If there are p of these parts of the rope that support the load W, then a balance of forces in the moving block shows that the tension in each of the parts of the rope string should be W/p. This means that the input force on the rope is T=W/p. Therefore, the block and rig reduce the input force by the factor p.

Operation method

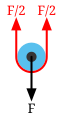

The simplest theory of operation for a pulley system assumes that the pulleys and lines are weightless. And that there is no loss of energy due to friction. Lines are also not supposed to stretch.

At equilibrium, the forces on the moving block must sum to zero. In addition, the tension in the rope must be the same for each of its parts. This means that the two parts of the rope that support the moving block must each carry half the load.

There are several types of pulley systems:

- Fix: A pulley fixed has a shaft mounted on bearings attached to a support structure. A fixed pulley changes the direction of force on a rope or strap that moves along its circumference. The mechanical advantage is obtained by combining a fixed pulley with a mobile pulley or other fixed pulley of different diameter.

- Movable: A pulley mobile has an axle in a mobile block. A single mobile pulley is supported by two parts of the same string and has a mechanical advantage of two.

- Composition: A combination of fixed and mobile pulleys forms a block and mates. A "block and gear" can have several pulleys mounted on the fixed and mobile axes, which further increases the mechanical advantage.

The mechanical advantage of the gun rig can be increased by interchanging the fixed and movable blocks so that the rope is attached to the movable block and the rope is pulled in the direction of the lifted load. In this case, the block and tackle is said to be "advantage shot". Diagram 3 shows that three parts of the rope now support the load "W", which means that the tension in the string is "W/3". Therefore, the mechanical advantage is three.

By adding a pulley to the fixed block of a gun rig, the direction of the pulling force is reversed, although the mechanical advantage remains the same, Diagram 3a. This is an example of the Luff tackle.

Free Body Diagrams

The mechanical advantage of a pulley system can be analyzed using free-body diagrams in which the force of tension in the rope is balanced by the force of gravity acting on the load. In an ideal system, massless, frictionless pulleys dissipate no energy and allow a change in direction of a rope that does not stretch or wear out. In this case, a balance of forces on a free body including the load, W and n support sections of a rope with tension T, gives:

The relationship between the load and the tension force that is exerted is the mechanical advantage MA of the pulley system,

Therefore, the mechanical advantage of the system is equal to the number of load-bearing rope sections.

Belt and pulley systems

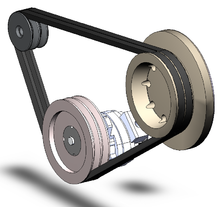

A belt and pulley system is characterized by having two or more pulleys in common with a belt. This makes it possible to transmit mechanical power, torque and speed through the shafts. If the pulleys have different diameters, a mechanical advantage is obtained.

A belt drive is analogous to a chain drive; however, a belt pulley may be smooth (devoid of discrete interlocking elements such as would be found on a chain sprocket, spur gear, or timing belt), so that the mechanical advantage is given approximately by the ratio of the pitch diameter of pulleys only, not fixed exactly by tooth ratio as in the case of gears and sprockets.

In the case of a drum type pulley, without a groove or flanges, the pulley is usually slightly convex to keep the flat belt centered. Sometimes referred to as a crowned pulley. Although once widely used on factory line shafts, this type of pulley is still found driving the rotating brush on upright vacuums, belt sanders, and band saws. Farm tractors built up to In the early 1950's they used to have a pulley for a flat belt (after which Belt Pulley magazine is named). It has been replaced by other mechanisms with more flexibility in the methods of use, such as the power take-off and hydraulics.

Just as the diameters of gears (and consequently their number of teeth) determine a gear ratio and thus the speed increases or decreases and the mechanical advantage they can provide, gear diameters pulleys determine those same factors. Tapered pulleys and stepped pulleys (which work on the same principle, although the names tend to apply to flat-belt versions and V-belt versions, respectively) are a way of providing multiple gear ratios in a drive system. belt and pulley that can be changed as needed, much like a transmission provides this function with a gear train that can be changed. V-belt stepped pulleys are the most common way drill presses provide a range of spindle speeds.

With belts and pulleys, friction is one of the most important forces. Some uses of belts and pulleys involve peculiar angles (leading to poor belt tracking and possibly belt slippage off the pulley) or low belt tension environments, causing unnecessary belt slippage. belt and, therefore, additional wear on it. To solve this, sometimes the pulleys are delayed. The term "lag" used to describe the application of a lining, cover, or wear surface with various texture patterns that is sometimes applied to pulley shells. The lagging is often applied to extend the life of the casing by providing a replaceable wear surface or to improve friction between the belt and the pulley. In particular, drive pulleys are often rubber coated (with a rubber friction layer) for precisely this reason.

Contenido relacionado

Radio network

Hawking radiation

Reradiation