Pendulum clock

The pendulum clocks are characterized by using an oscillating weight to measure time. The pendulum's advantage in measuring time accurately is that it is a harmonic oscillator: its swing cycles occur at equal time intervals, depending solely on its length (discounting the effects of movement resistance). From its invention in 1656 by Christiaan Huygens until the 1930s, the pendulum clock was the most accurate timekeeping system available, and its use became widespread. Throughout the 18th and 19th centuries, clocks pendulum, ubiquitous in homes, factories, offices, and railway stations, served as the main reference for scheduling daily life, work shifts, and public transportation. Its precision allowed us to adopt the faster pace of life typical of the Industrial Revolution.

Fandum clocks must remain in a fixed position to operate correctly; any displacement or acceleration affects the movement of the pendulum, causing inaccuracies in its operation, which is why they cannot be used as portable watches. Since the widespread use of quartz clocks, pendulum clocks are mostly kept for their decorative value and as antiques.

History

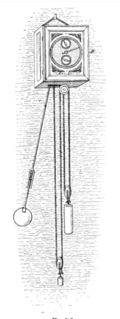

The pendulum clock was invented in 1656 by the Dutch scientist Christiaan Huygens, and was patented the following year. Huygens commissioned the watchmaker Salomon Coster to build his designs, and was inspired by the pendulum investigations begun by Galileo Galilei around 1602. Galileo discovered the key property that makes pendulums useful for timekeeping: isochronism, which means that its period of oscillation depends only on its length. Galileo had the idea of the pendulum clock in 1637. His son began its construction in 1649, but never finished it. The introduction of the pendulum, the first harmonic oscillator discovered, increased enormously the precision of the clocks, which went from about 15 minutes a day to about 15 seconds a day, promoting with its rapid acceptance that the old 'foliot' adapted to add a pendulum to their primitive mechanisms.

These old adapted clocks, due to the type of their escapements, had pendulums with oscillations of up to 100° amplitude. In his 1673 analysis of pendulums, Horologium Oscillatorium, Huygens showed that large oscillations made the pendulum inaccurate, causing irregularities in its frequency, and therefore in the speed of the clock. He came to the conclusion that only pendulums with small oscillations of a few degrees are isochronous, which led to the invention of the lever escapement around 1670, allowing the pendulum oscillation to be reduced to values between 4° and 6th. The lever became the standard escapement used in pendulum clocks. In addition to greater precision, the reduced pendulum movement required by the anchor system made it necessary to adopt longer pendulums, which require less energy and cause less wear on the movement. The seconds pendulum (also called the 'Royal pendulum'), 0.994 m long, with each oscillation lasting one second, became widely used in quality watches. The first clocks with their characteristic long and narrow boxes around these pendulums, were built around 1680 by William Clement, they became famous, and were known as the longcase clock or grandfather clock >. The increased precision resulting from these advances led to the appearance of the (previously very rare) minute hand, which was added to clock faces around 1690.

The wave of watchmaking innovations in the 18th and 19th centuries that followed the invention of the pendulum brought many improvements to pendulum watches, such as the recoilless escapement invented in 1675 by Richard Towneley and popularized by George Graham around 1715 in its precision watches, with the new "regulator" which gradually replaced the lever escapement and is used in most modern pendulum clocks. The observation that pendulum clocks lost time in summer showed that the expansion and contraction of the pendulum rod with changes in temperature was a source of appreciable error. This was solved by the invention of temperature-compensated pendulums: George Graham's mercury pendulum in 1721; and John Harrison's grill pendulum in 1726. With these improvements, precision mid-century pendulum clocks XVIII achieved accuracies of a few seconds per week.

Until the 19th century, clocks were built by hand by individual craftsmen and were very expensive. The rich ornamentation of pendulum clocks from this period indicates their value as status symbols for the upper social classes. In Europe, watchmakers from each country and region developed their own distinctive styles. In the 19th century, the creation of watch factories made pendulum clocks gradually affordable to middle-class families.

During the Industrial Revolution, daily life in homes was organized around the pendulum clock. More accurate pendulum clocks, called regulators, were installed in business centers and were used to schedule work and set the time on other clocks. The most precise, known as astronomical regulators, were used in astronomy observatories, in topography, and in astronomical navigation. In the early 19th century, the astronomical regulators of naval observatories served as the primary standards for setting the time of each country. Since 1909, the "US National Bureau of Standards" (later renamed NIST) sets the standard of time in the United States using pendulum clocks fitted with Riefler escapement, with accuracies approaching 10 milliseconds per day. In 1929 he switched to free pendulum clocks of the Shortt-Synchronome type, shortly before the gradual introduction of the quartz clock, which became the standard in the 1930s. With an error of about one second per year, the Shortt was the most accurate commercially produced grandfather clock. Pendulum clocks have been the world standard for precision timekeeping for 270 years, until the invention of the quartz clock in 1927, and were used as time standards throughout World War I. The French Time Service used pendulum clocks as part of its standard set of clocks until 1954. The pendulum clock began to be replaced in homes during the 1930s and 1940s by the electric clock, which gave more accurate time. because it was synchronized with the oscillation of the electrical network. The most accurate pendulum clock to date (2007), was the experimental Littlemore clock, built by Edward T. Hall in the 1990s. (donated in 2003 to the Clock Museum, Columbia, Pennsylvania, USA).

Mechanism

All mechanical pendulum clocks have at least these five parts:

- A power source; either a weight on a string or string (which triggers a pulley or a dented wheel), or a spring.

- A gear or wheel train that intensifies the speed of power supply so that the pendulum can use it.

- An escape that gives the pendulum the precise synchronized impulses to keep its balance, and that releases the gear train wheels to advance a fixed amount to each oscillation. This is the source of the "tic-tac" sound characteristic of an ongoing pendulum clock.

- The pendulum, with a weight mounted on a rod.

- An indicator or marker that shows the records of the frequency with which the escape has rotated, that is, the amount of time elapsed, usually with the traditional game of needles (horaria, minute and sometimes seconds) on one or several numbered spheres.

In watchmaking, additional functions on watches (other than telling normal time) are called complications. More elaborate pendulum clocks may include the following complications:

- Sound watch - every hour hits a bell or gong, with the number of touches equal to the number of the hour. More elaborate types, technically called Carrylon watches, mark the quarters of the hour, and can interpret various melodies, such as the popular touch of the rooms of Westminster that sounds regularly from the Big Ben of London.

- Calendar - indicators showing the day of the week, the day of the month, and sometimes the month.

- Fases of the Moon - Dial showing the phases of the moon, usually with a drawing of the moon painted on a rotating disk.

- Midday - this rare complication was used in the first days to know the sun pass by midday. It shows the difference between the time indicated by the clock and the time indicated by the position of the sun, which varies in up to ± 16 minutes during the year.

- Repeater - designed to give the time by bells when a pusher is activated manually. This rare complication was used to check what time it was at night, before the generalization of artificial lighting.

There are also electromechanical pendulum clocks, which are used in mechanical master chronographs. The power source is an electric solenoid that provides impulses to the pendulum by means of magnetic force. The escapement is replaced by a switch or a photodetector that determines when the pendulum is in the correct position to receive the impulse. They should not be confused with the more recent quartz pendulum clocks, in which an electronic module (quartz clock) swings a pendulum. These devices are not true pendulum clocks because the timekeeping is controlled by a quartz crystal module, and the swinging pendulum is merely a decorative simulation.

Effects on the swing of the pendulum

The pendulum swings with a period that varies as the square root of its effective length. With small oscillations, the period (T) is short (on the order of seconds). Then, for the time of a complete cycle (two oscillations in the opposite direction), it is necessary to:

| Symbol | Name | Unit |

|---|---|---|

| T{displaystyle T} | Period | s |

| L{displaystyle L} | Pendulum length | m |

| g{displaystyle g} | Acceleration of local gravity | m/s2 |

All pendulum clocks have a system for adjusting the pendulum to local gravity conditions. This is usually an adjustment nut located under the pendulum, which moves the mass of the pendulum up or down on a threaded stem. If it moves up, the effective length of the pendulum is reduced, the period of oscillation is shortened, and the clock goes faster. On some pendulum clocks, fine adjustment is done with an auxiliary system, which may be a small weight that moves up or down on the pendulum rod. On some main clocks and tower clocks, adjustment is made by a small pan mounted on the rod, where small weights are attached or removed to change the effective length, so the rate can be adjusted without stopping the clock.

If the amplitude of a pendulum's oscillation is considerable, its movement becomes more irregular, and its period fluctuates. On the other hand, when limited to small oscillations of a few degrees, the pendulum is practically isochronous; that is, its period is independent of changes in the amplitude of motion. Therefore, the oscillation of the pendulum in clocks is limited to values between 2° and 4°.

Thermal compensation

One source of error in these clocks is that the pendulum rod varies in length slightly with changes in temperature. An increase in temperature causes the rod to expand, making the pendulum longer, so its period increases and the clock will tend to lose time. Wood expands much less than metals, which is why many high-quality clocks had their pendulum rods made of wood. To compensate for this effect, the first high-precision clocks used mercury pendulums , invented by George Graham in 1721. These clocks had the pendulum weight consisting of a container filled with mercury. An increase in temperature causes the rod of the pendulum to expand, but the mercury in the container would also expand, and its level would rise slightly in the container, keeping the center of gravity of the pendulum at the same height.

The most widely used temperature-compensated pendulum was the "grill pendulum," invented by John Harrison in 1726. This system consists of a "grid" of parallel bars of a metal with high thermal expansion (such as zinc or bronze) and another of bars of a metal with low thermal expansion (such as steel), which are mounted on a frame in opposite directions. It was constructed so that the high expansion rods compensated for the change in length of the low expansion rods, achieving zero length change with temperature variations. This type of pendulum has become a symbol of quality, which is why it is common to see clocks with "fake" (which have no real temperature compensation function) for purely decorative reasons.

Some of the high-precision scientific clocks, built around 1900, had "high-tech" in his time, using low-expansion materials such as nickel-steel alloy (invar) or fused silica.

Atmospheric friction

The viscosity of the air through which the pendulum swings varies with atmospheric pressure, humidity, and temperature. This drag also requires energy that could otherwise be applied to extend the running time each time the watch is wound. Traditionally, the pendulum is made with a narrow lenticular shape, optimized to reduce air resistance, which is where most of the drive power is lost in a quality watch. Late 19th century and early XX, the pendulums of precision master clocks used in astronomical observatories, were often located in a low-pressure chamber from which air had been pumped, thereby reducing resistance and making the operation of the lowercase pendulum even more accurate.

Leveling and "rhythm"

To keep time accurately, pendulum clocks must be perfectly level. If they are not, the pendulum swings more to one side than the other, upsetting the symmetrical operation of the exhaust. This condition can often be seen audibly in the "tic-tac" of the clock. The "beats" they must be located at evenly spaced intervals, accurately enough to produce a "tick...tock...tick...tock" sound; if they are not, and have the sound "tic-tac... tic-tac...", the clock is out of beat and should be leveled. This problem can easily cause the watch to stop working, and is one of the most common causes of failure. With the use of a spirit level or timing machine, a more precise adjustment can be achieved than by relying on the 'beat' sound. Precision watches often have a built-in spirit level for this task. Some models have feet with adjustable screws to facilitate leveling; the more modern ones have an automatic leveling adjustment as part of the movement. Even certain types of modern pendulum clocks have self-regulating rhythm synchronization devices, and this adjustment is not necessary.

Local Gravity

Since the weight of the pendulum will increase with increasing gravity, and local gravity varies with latitude and elevation of the Earth, pendulum clocks must be reset to keep correct time when moved from one location to another. For example, a grandfather clock moving from sea level to an altitude of 4,000 feet (1,219.2 m) will lose about 16 seconds per day for this reason. Even moving a clock to the top of a tall building will cause it to be delayed by an appreciable amount of time due to less gravity.

Torsion pendulum

Also called a torsion spring pendulum, it is a circularly symmetrical mass (often four spheres on radial arms) suspended from a vertically arranged spring steel wire. It is used as a regulation mechanism in torsion pendulum clocks. The rotation of the pendulum twists the suspension spring in both directions alternately, taking advantage of the momentum of the energy applied to the upper part of the wire. As the period of one cycle is quite slow compared to the swing speed of a normal pendulum, it is possible to make these clocks only need to be wound only once every 30 days, or even only once a year or more.. Models with one year of operating autonomy are sometimes called "400-day clock", "perpetual clock" or "anniversary watch", the latter is sometimes given as a gift to commemorate wedding anniversaries. Companies like Schatz and Kundo, both German, were the main manufacturers of this type of watch. The operation of this type of pendulum is independent of the local force of gravity, but it is more affected by changes in temperature than an uncompensated swinging pendulum.

Escape

The escapement drives the pendulum, usually via a gear train, and is the part that makes the "tic-tac" of the clock. Most escapes have a lock state and a move state. In the locked state, nothing moves. In the movement phase, the pendulum drives the escapement position, while the escapement pushes the pendulum at some point in the swing cycle. A notable but rare exception to this principle is John Harrison's grasshopper escapement. In precision watches, the escapement is often driven directly by a small weight or spring that is reloaded at regular intervals by a separate mechanism called a remontoire. This frees the exhaust from the effects of variations in the gear train. In the 19th century, electromechanical escapements were developed. In these, a mechanical switch (or a photoelectric cell) in combination with an electromagnet makes it possible to maintain the oscillation of the pendulum. These escapement systems were used in some of the most accurate watches known to date. In astronomical pendulum clocks, casings in which a vacuum is made are usually used. The pulse of electricity that drives the pendulum can also control a plunger to move the gear train.

In the 20th century, W.H. Shortt invented a free pendulum clock accurate to one hundredth of a second per day. In this system, the timing pendulum does no work and is kept oscillating by the impulse of a weighted arm (gravity arm) which is brought down on the pendulum by another clock (slave) just before it is needed. The gravity arm then pushes the free pendulum, preventing it from going out of range, while synchronizing with the free pendulum. Once the gravity arm is released, a mechanism is triggered to reset the pitch by the slave clock if necessary. The entire cycle is kept in sync by a small diaphragm spring located in the pendulum of the slave clock. The slave clock is set to run with a slight delay, and the gravity arm reset circuit activates a pivoting arm that only contacts the tip of the diaphragm spring. If the slave clock has lost too much time, the diaphragm spring pushes it against the arm and this speeds up the pendulum. The amount of this gain is such that the diaphragm spring is not involved in the immediate cycle, but is involved in the next. This type of watch became the standard for use at observatories from the mid-1920s until it was superseded by quartz technology.

Hour indicators

The display system is almost always the traditional "clock face" with moving hour and minute hands. Many watches have a small third hand indicating the seconds on a subsidiary dial. Pendulum clocks are generally designed to be set by opening a glass cover that protects the dial, and manually pushing the minute hand around its axis until the correct time is reached. The minute hand is mounted on a sliding friction sleeve that allows it to be rotated on its axis. The hour hand does not release from the gear train. From the axis of the minute hand, a small set of gears is arranged, which synchronously move the hour hand when the minute hand is turned manually.

Styles

Fandulum clocks are more than just utilitarian instruments for measuring time; they were symbols of social class that expressed the wealth and culture of their owners. They evolved into various traditional styles, specific to each country and era, and depending on the use to which they were to be put. Their outward appearance sometimes reflects the style of furniture popular during the corresponding period. Experts can often identify a vintage watch's construction date by looking at subtle details on cases and dials. Here are some of the different types of pendulum clocks:

- Clock Act of Parliament

- Watch Banjo

- Bracket watch

- Cartel watch

- Comtoise or Morbier watch

- Cuckoo clock

- Longcase watch (commonly known as a standing watch)

- Clock flashlight

- Clock

- Master watch

- Ogee

- School regulator clock

- Shortt-Synchronome watch

- Torsion pendulum clock (uses a torsion pendulum)

- Watch Torreta

- Vienna Regulatory Watch

- Clock Zaandam

Contenido relacionado

Russian painting

Spanish subgroup

Vapor pressure