Paper

The paper is a material made up of a thin sheet that is made from cellulose pulp, prepared with a paste of ground vegetable fibers suspended in water, generally bleached, and subsequently dried and hardened, to which substances such as polypropylene or polyethylene are normally added in order to provide it with special characteristics. The fibers that make it up are held together by hydrogen bonding.

Etymology

According to the DRAEː of cat. paper, east of lat. papȳrus 'papyrus', and this from gr. πάπυρος pápyros.

History

In Ancient Egypt, writing on papyrus began before the year 3000 BC. C. It was made from a very abundant plant on the banks of the Nile River, Cyperus papyrus, and was the first material that presented properties associated with paper. Later, in Greco-Roman antiquity, papyrus shared popularity with paper. parchment, which would be prevalent in Europe during the Middle Ages. The parchment consisted of calf, sheep, goat or ram skins tanned with lime and prepared to receive the ink. However, this process was expensive, so from the VIII century it was customary to erase the texts of the scrolls to rewrite over them (giving rise to palimpsests), thus losing an inestimable amount of creations.

The paper

Before paper was invented, Chinese scribes wrote using a rigid tip on strips of wood or bamboo, but these materials did not make writing easier and were problematic for archiving. After the introduction of the hair brush, the support was replaced by early attempts to make paper from waste cloth, silk, rice straw and hemp, and even cotton. The first process is traditionally considered to be The modern paper-making method was developed by the eunuch Cai Lun, advisor to Emperor He of the Eastern Han Dynasty, in the II< century. /span>. His innovation consisted in the use of vegetable fibers with a high cellulose content extracted from mulberry, ramie and cotton, as well as old rags and cloth. He placed the material in a mortar with water and crushed it until obtaining a homogeneous and compact paste that he then laminated and dried.

For about 500 years, the art of papermaking was confined to China; but in the year 610 a Korean monk introduced its method of manufacture to Japan, from morus, gampi and mitsumata leaves, and around 750 it passed to Central Asia. The knowledge was then transmitted to the Arabs, who They would then be introduced into Spain in the XI century, establishing the first European paper mill in Játiva (year 1056). The first document on paper in Europe is a letter dictated in Spanish and written in Greek and Arabic characters that Countess Adelaide sent in 1109 to her son Roger, the future King of Sicily. This new writing material arrived in Paris, through Spain, coinciding with the inauguration of the University in that city. From this moment the technique spread to Sicily in the 12th century and Italy (13th century) and the South of France (S. XIV). From where it spreads throughout the continent, creating paper mills in Italy, in the Champagne region (France) and the Netherlands, which implied the introduction of watermarks or watermarks to identify the source of the paper.

In Europe, the only raw material used was linen and cotton rags, so the advent of printing generated an increase in the use of paper from the 19th century XV, causing a shortage of these materials. Although attempts were made to use other materials as substitutes, none were commercially successful until 1845, when a German industrialist introduced the mechanical process of grinding wood shavings to make the pulp, a procedure that, however, left behind an acid, lignin., which when oxidized with the oxygen in the air burned, cracked and cracked the paper turning it yellow, so that the paper, which until then could resist some five hundred years without deterioration by xylophagous insects, saw its durability considerably reduced, even though this acid would make the paper poisonous to xylophages; Currently, only the coarsest and worst quality paper, which is the ephemeral used in newspapers, contains lignin. In 1850 the first chemical process was introduced.

Since then, paper has become one of the emblematic products of our culture, being made not only from old rags or cotton but also from a wide variety of vegetable fibers; In addition, the growing invention of dyes allowed a generous supply of colors and textures. With the help of mechanical printing, at first xylographic (that is, with a wooden matrix; the first book printed in this way was in China, the Diamond Sutra, 868) and later by means of movable type of lead according to Gutenberg's printing press in 1453.

Although paper can now be replaced for certain uses by synthetic materials, it continues to hold great importance in our lives and in our daily environment, making it a personal item and therefore difficult to replace.

The appearance and rapid rise of information technology and new telecommunication systems allow the writing, storage, processing, transport and reading of texts with more advantageous electronic means, relegating traditional supports, such as paper, to the background.

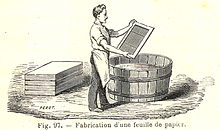

Traditional paper manufacturing

In essence, in the traditional papermaking process, a slurry of fibers is made in water and drained through a screen, producing a layer of randomly interlocked fibers. Immediately afterwards, the water is removed from this layer by pressing and drying. In the past, these fibers were extracted from rags or old cotton or linen garments, or from the hemp plant. The first machine to replace the manual production process was built in 1798 and later improved in 1803 under the name of the Fourdrinier machine.

Subsequently, most paper has been made from wood pulp, due to its lower cost. However, textile fibers will continue to be used to this day for the manufacture of high-quality paper.

Paper making (20th and 21st centuries)

The following describes different processes that are currently used to make paper:

- Trap clamp

- It is created from cotton fibres, linen or hemp. It was the main way to make paper until the middle of the centuryXIXwhen the production of wood pulp paper began. In the first half of this century you can find machine-shaped rag papers. The process to get the rag pulp is as follows:

- Classification (is separated by the type of fiber and fabric status)

- Troceado (cuts are cut to a uniform size)

- Washing (cleaning impurities)

- Whitening (inks and dyes are removed)

- Macerado (it leaves the cloth "pudrite" in a watered tub)

- Battery (the fabrics are beaten with wooden bushes while a water current cleanses the impurities until they are completely undone with what is generated by the defibrate). The defibrado material is mixed with water until you get a paste, which is extracted from the container by means of a mould or mesh allowing the filtration of the water, to then be pressed and dried to obtain the cloth paper sheet. Most of this type of paper presents verbid and watermark.

- Mechanical wooden clap

- Starts production in the middle of the centuryXIX, and is composed of pulp made from wood fibers. The highest percentage of the pulp of this paper comes from mechanical processes, so the fibers are small and weak, besides having a certain percentage of lignin, which eventually makes it yellowish and brittle.

- By the end of the centuryXIX other processes were developed to obtain paper from wood such as those of chemical pulp, in which the lignin is eliminated by generating more resistant papers to those of mechanical pulp.

- There are two types of chemical pulp: the one generated to the sulphite, in which the pulp of wood is warmed and added sulfurous acid and calcium bisulfite, and the one generated to sulfate, in which the bisulfite is replaced by sodium sulphate: Most of these papers are of smooth appearance and do not have versed.

- Brunette cake

- It is obtained simply by defibrating the wood after having washed and boiled (to remove embedded materials and facilitate the defibration). You get a long and resistant fiber paste. It is used for cartons, packaging paper, paper bags, etc.

- Strawberry pie

- It is obtained from cereals and rice. It has a yellowish colour and is used for the elaboration of butcher papers and for the inside of the wavy carton.

- Cutting paste

- Paper cut is mixed with pasta to lower costs. Where appropriate the cut is divided into the following categories:

- Coil cuts: at the factory when cutting coils, good quality papers.

- Guillotine: here it is classified according to the whiteness, composition, etc.

- Domestic cuts: these come from offices, to produce low-quality papers.

- Street or printed: only used to manufacture gray cardboard.

Types of paper

- Wallpaper crystal

- Translucent paper, very smooth and resistant to fats, manufactured with very refined and subsequent cocooned chemical pastes. It's a superior quality similsulfurized heavily grounded. Transparency is essential property. Hard paper, quite sound, with little hand, sensitive to hygrometric variations. Because of its impermeability and beautiful presentation, it is used in luxury packaging, such as perfumery, pharmacy, confectionery and food. Lively composed by jealousy or imitations.

- Stretch paper

- Paper manufactured mainly from recovered paper (papelote) without classifying.

- Free acid paper

- In principle, any paper that does not contain any free acid. During its manufacture special precautions are taken to remove any active acid that may be in the composition, in order to increase the permanence of the finished paper. The most common acidity comes from the use of aluminum to precipitate the colophon resins used in gluing, reagents and residual products of money laundering (chlorine and derivatives) and the absorption of acidic gases (nitrogen and sulfur oxides) of surrounding contaminated atmospheres. An acid paper manufacturing process is incompatible with the production of durable papers.

- Rolling paper

- A role to smoke or play is a role that is used to make cigarettes. Smoking paper has an engomated end, with a gramage ranging from 12 to 25 g/m2 depending on its composition, brands and uses. Among the most renowned brands we can name three of the most popular, Smoking, OCB and Rizzla.

- For its finesse, the smoking paper can be used in a tool machine, to help the operator when you have to delay the tool (with the work surface).

- Paper kraft

- High resistance paper manufactured basically from chemical paste kraft (to sulfate). It can be raw or whitened. Sometimes, and in some countries, it refers to the paper manufactured essentially with raw kraft pastes of conifer woods. Crude is widely used for wraps and packaging and whitening, for accounting, records, records, official documents, etc. The term comes from the German word for resistance.

- Linear paper

- Light or medium gramage paper used on the covers, external faces, of the undulating cartons. It is called kraftliner when in its manufacture it is used mainly pasta to virgin, raw or whitened sulfate (kraft), usually of conifers. The quality in which recycled fibers are used is called testliner, often made up of two layers.

- Paper (carton) multilayer

- Product obtained by combination in wet state of several layers or strips of paper, formed separately, of equal or different compositions, which adhere by compression and without the use of any adhesive.

- Vegetable parchment paper

- True sulfurized paper.

- Simil-pergamino paper

- True sulfurized paper.

- Toilet paper

- The toilet paper (also called toilet roll, toilet paper, toilet paper or toilet paper) is a type of fine paper that is used for anal and genital cleaning after the act of defecation or urination. It may be perfumed or not. Its most common format is the paper roll, but it is also possible to find it in packages. It is usually sold in markets, supermarkets and pharmacies in packages of several units. The paper is usually designed to decompose in contact with the water, contrary to the paper towels for the hands. In some cases special papers are produced to avoid damaging or jamming septic wells.

- Similsulfurized paper

- Paper free of mechanical paste that has a high resistance to fat penetration, acquired simply by means of an intensive mechanical treatment of the paste during the refined operation, which also produces an extensive gelatinization of the fibers. Its porosity (permeability to gases) is extremely low. It differs from the true sulfurized in that by dipping it in water, for a sufficient time, variable according to quality, the simile loses all its resistance while the sulfurized preserves its solidity at least in part.

- Sulfurized paper

- Paper whose essential property is its impermeability to fatty bodies and also a high resistance in wet and good waterproofing and resistance to water disintegration, even in boiling. Waterproofing is obtained by passing the paper sheet for a few seconds by a concentrated sulfuric acid bath (75 %, 10 °C) and subsequent elimination of acid by washing. In contact with acid, cellulose is partially transformed into hydrocellulose, gelatinous matter that obstructs the pores of paper and makes it waterproof.

- Paper tissu

- Low-grain paper, soft, often slightly crespated in dry, composed predominantly of natural fibers, virgin or recycled chemical paste, sometimes mixed with high-performance paste (chemical-mechanics). It is so thin that it is hardly used in a simple layer. Depending on the requirements, two or more layers are usually combined. It is characterized by its good flexibility, surface softness, low density and high capacity to absorb liquids. It is used for hygienic and domestic purposes, such as handkerchiefs, napkins, towels and similar absorbing products that are disintegrated in water.

- Permanent role

- A role that can withstand major physical and chemical changes over a long period (various hundreds of years). This paper is generally acid free, with alkaline reserve and a reasonably high initial resistance. Traditionally the cultural community has considered it crucial to use high purity fibres (lino or cotton) to ensure the permanence of the paper. Today, it is considered that less emphasis should be placed on the type of fiber and more on manufacturing conditions. An acid manufacturing process is incompatible with the production of permanent papers.

- Fluting paper

- Paper made expressly for its indulation to give it stiffness and damping properties. Normally manufactured from semi-chemical paste of hardwoods (neutral sulfite process, NSSC), high-performance cereal straw paste or recovered paper, is used in the manufacture of undulating cartons.

- Stone paper

- It is a combination of calcium carbonate (80 %) with a small amount of nontoxic resins (20 %) to create a strong sustainable substrate. Calcium carbonate comes mostly from waste from the construction industry, such as marble, limestone and plaster, which are ground in a very fine powder. Polyethylene comes in part from recycled post-industrial residues and acts as a link for calcium carbonate. The symbiosis of these materials is a product that resists strongly, both water and breakages. It is a process of ecological manufacture and of the most modern, during the production process energy consumption represents approximately 50% of what is consumed by making normal paper paste, it is not necessary to use water for anything and no toxic gas is issued.

- Paper China

- The first Chinese papers were created from cocoons and silk residues embedded in water, which were grinded and pulverized, and that adding water was reduced to a clay that spread over a very fine branches mat. The water was filtered through the mat and the mud by drying gave rise to a fold of paper but of poor quality for writing. Therefore, given their characteristics of malleability, they were used mainly to wrap, make lamps or lamps and comets (papallets, barrels, potatoes, etc.). To give the delicate paper more attractive, it was added sometimes color.

Properties

- Durability of paper

- The durability mainly expresses the ability of the paper to perform its functions during intensive and continuous use, without reference to long periods of storage. A paper can be durable (by resisting intensive use for a short time) but not permanent (due to the presence of acids that slow down cellulose chains).

- Dimensional stability

- Ability of a paper or cardboard to retain its dimensions and planity when it changes its content in humidity, for example, under the influence of variations in the surrounding atmosphere. A high content in hemicelulose promotes the swelling of the fibers and their instability.

- Hand

- Term applied to a paper that expresses the relationship between its thickness and gramage. Its value decreases when compaction and leaf density increase.

- Permanence

- It refers to the retention of significant properties of use, especially mechanical resistance and color, after prolonged periods. A paper can be permanent (retains its initial characteristics) but not durable, due, for example, to its low initial resistance.

- Resilience

- Paper capacity to return to its original form after being curved or deformed. The presence of mechanical pasta in the composition confers such property.

- Carting

- Combination of touch and sound that produces a sheet of paper when stirring manually.

- Permeable

- The ability to get penetrated by liquids is high.

Stages of the process

- refined

- The pasta is refined to defibrate and cut the fibers in order to adapt them to the desired type of paper. From this process depends the degree of resistance that the paper will have to the fold, busted and torn.

- The paper can suffer two types of refinement: fat or wizard:

- the fat leaves the very hydrated fibers with the role of resistance, stiffness and some transparency, but it removes flexibility and makes it brittle, with difficulty for folding (plant paper, smoking, parchment).

- the wizard leaves the entire or truncated fibers, which gives the paper flexibility, ease for folding, thickness, softness and opacity (for example, absorbing, printing, offset, etc.).

- Cold

- At this stage, you add glue to the paper, to avoid that on paper corra the ink when printing or writing. The degree of permeability depends on this process.

- The gluing can be done in two moments: mass or surface:

- mass is done in the course of manufacture, at the time when the masses are prepared (the pasta).

- on surface when the paper is almost dry, in the third of the drying.

- The glue consists of the addition of hydrophobic products such as resin tails, gelatin, reinforced tails and fixed products such as aluminum sulfate (called frequently and incorrectly allumina sulfate).

- The purpose is to avoid the penetration of fluids in the paper that cause resistance and printing problems (e.g. characters may lose sharpness).

- Mass gluing delays fluid penetration through the wrapping into materials. Porosity decreases if jellies are used as a tail. Softness also decreases as the substances used are less white than cellulose. The opacity also decreases (in general the gluing decreases the physical characteristics of the papers such as folds, lengthening, bursting, etc.).

- It also serves to favor the retention of the next step: the incorporation of loads and the improvement of color uniformity.

- Cargo

- They are powdered products (usually from rock grinding) that contribute to giving body to paper, in addition to contributing substantially to other features such as reducing shine, increasing mechanical resistance, creating a suitable microporosity for its breathability, facilitating its sanding, increasing its filling power, etc.

- The most commonly used loads are minerals such as limestone (calcium carbonate), caolin, mica, talc, silica, plaster, baritin (barium sulphate) or organic substances such as potato, starch, etc.

- Since the loads are more economical than cellulose, the price of the paper decreases. The loading products fill all the gaps between the fibers, so the paper acquires a uniform surface while softening, reduces its transparency and improves the conditions for printing.

- The softness of the paper, its brightness or opacity, depends on the kind of cargo product. The finest grain, for example, produces greater opacities and a higher whiteness. The loads are products that give body to the paper that does not possess much cellulose. The proportion of loads added to pastas varies proportionally to their quality (more load, worse quality).

- Pigments

- Like the loads, fill the holes of paper giving more opacity and softness. They differ from these by the way they apply and because the particles are smaller. The pigments are applied on surface and mass loads.

- Coloring

- It is added to the pasta coloring substances of mineral or organic nature (according to the type of paper). The colors obtained from mineral substances are more light resistant than organic derivatives.

- You can add the mass color (in the mixers) or in some types of paper it is made when the sheet is formed in the continuous machine.

- Optical Blanket Agent (A.B.O.)

- The optical laundering agent is used to give a visual effect of greater whiteness to paper. He is responsible for seeing that bluish shine when the paper is under an ultraviolet light.

- League

- Due to the organic character of the fibers and the inorganic character of some additives (loads, pigments...) the ligants are needed to be able to unite them. These create "bridges" that bind the additives between themselves and then bind them to the fiber. The most used are:

- starch

- latex

- Polyvinyl alcohol.

Manufacturing processes (continuous machine)

The refined paste passes into reserve tanks (called vats) where agitators keep the paste in continuous movement. It then goes through a probabilistic scrubber and a dynamic or cyclonic scrubber. The probabilistic purifier separates the large and light impurities (plastics, chips...) and the dynamic ones separate the small and heavy impurities (sand, staples...) Then the paste is taken to the input box through the distributor, which transforms the cylindrical shape of the paste (it reaches the vats through a distribution network of pipes) in a wide and thin sheet.

Then it reaches the manufacturing table, which contains a metallic bronze or plastic mesh, which, by constantly rotating on the rollers, acts as a sieve that allows part of the water to drain, and at the same time performs a transverse vibration movement to intertwine the fibers. The fabrics are transported to the paper by dewatering or vacuum elements, among them we find the foils, the vacuofoils, the suction boxes, the dewatering roller or Dandy Roll and the suction cylinder. The function of these elements is to absorb the water that is next to the fibers, making the sheet have a good profile (thickness) homogeneous throughout the width.

Then the sheet is passed through the presses. These are provided with cloths that transport the paper and at the same time absorb the water from the sheet when it is pressed by the presses. Wet pressing consists of 4 phases:

- 1.a phase, compression and saturation of the sheet

- The air leaves the spaces between fibers and their space is occupied by water, until reaching the saturation of the leaf, which is when the leaf cannot absorb more water.

- 2.a phase, compression and saturation of the bayeta

- Hydraulic pressure is created on paper and water begins to move from paper to berry until it reaches the saturation of this.

- 3.a phase, expansion of the bayeta

- The bayette expands faster than the paper and continues to absorb water to the maximum dryness of the leaf

- 4.a phase, expansion of the sheet

- It creates a negative hydraulic pressure and the water returns from the berry to the paper, at this moment you have to separate the berry leaf as quickly as possible.

After wet pressing, the sheet passes to the dryers where it is dried by means of cylinders that are fed with steam. The sheet is transported by cloths that exert pressure on the dryers to facilitate the evaporation of water from the sheet.

From the dryers the paper reaches the calandria or calender. These are vertically superimposed cylinders pressed together inside which steam can circulate to heat the paper, or water to cool it (depending on the type of paper to be manufactured). This gives the paper a slight smoothing that can be definitive (if smoothed paper is being manufactured) or preparatory for the glossy calender (in which, depending on the intensity of the pressure of the cylinders, it is obtain different glossy). This process, in addition to smoothing and compacting the structure of the paper, gives the surface of the paper a greater shine.

Finally, the paper reaches the folder where it is collected on a reel.

Manufacturing

The fibers for their manufacture require special properties, such as high cellulose content, low cost and easy to obtain, so the most commonly used are vegetable fibers. The most common raw material is cellulose pulp, coming from wood from trees, mainly pines, due to its price and the quality of its fiber (very long), and eucalyptus, since it is very cheap and resistant. Other materials are also used, such as cotton and hemp. Depending on the type of raw material used and the process to which it has been subjected, the products obtained will be different in terms of the quality of the paper pulp, as well as the types of paper and cardboard. Likewise, it will also depend on the type of machinery used in each process.

The production of paper is described, since the process of obtaining pulp or pulp is a totally different topic.

Preparation of the fibers

Recycled paper

Obtaining paper with recycled raw materials. The steps of forming the sheet and its handling are the same. The difference is that the material used is already paper. This is obtained for the most part from publishing leftovers (better quality, less used, cleaner and more homogeneous) and selective collections (dirtier paper because it is used and its exact composition is unknown, newspapers mixed with magazines, cardboard boxes used, etc).

Virgin pulp paper

Once you have the cellulose pulp, obtained by chemical means (chemical pulp or Wood Free, which is obtained by dissolving the lignin) or mechanical means (mechanical pulp, which does not eliminate lignin but separates the fibers by friction), it must be conditioned for the manufacturing process.

Pulper

The paste is prepared in a device called a pulper (a device similar to a large mixer), where water is mixed with the pulp. The pulp can be in the form of bales and bales (many sheets of pulp), in bulk (shredded pulp) or, if it is an integrated mill where both pulp and paper processing take place in the same mill, in water suspension.

The pulper is a large vat, normally below ground level, inside which there is a large propeller. By adding the paper pulp, the fiber disintegration process begins, first by the impact of the bales falling, then by the friction of the propeller with the pulp and finally by the friction of the fibers themselves. This action generates heat that helps dispersion.

Depending on the type of production, old paper can be used, obtaining a lower quality paper (recycled paper). Although it is always mixed with virgin pulp, since the fibers spoil, break and are no longer useful for manufacturing. It is impossible to recycle or reuse paper indefinitely.

Refine

Next, the suspended fibers have to be physically treated through a friction process, to increase their ability to "felt" and bond with each other. This process is called "refining." It consists of rubbing the fibers together and against metal discs. This causes them to partially break and create a kind of hairs which are the ones that will create the hydrogen bonds and give the paper greater tensile strength.

Each type of paper fiber and each type of paper use a different refinement that is adapted to each need. As the degree of refinement of a paste increases, its opacity decreases, its tensile strength increases, and its porosity decreases. Thus, the onion skin (typical paper used in drawing, semi-transparent) is highly refined.

Once refined, it passes through various vats (liquid containers) where additives are added such as dyes, mineral fillers (to add whiteness, reduce porosity, etc.), special products (to increase resistance to water, tensile strength, etc.).

Once all the necessary elements have been added and the pulp has rested for a short time to eliminate latency (the propensity of the fiber to tangle, becoming clumps), it arrives at the paper machine where it will be treated for be then dried in a drying place.

The paper machine

It is the most important element. It is the place where the pulp in suspension becomes paper. Although there are several types, the most widespread is the flat table machine, derived from the first machine invented by Fourdrinier in Napoleon's time.

It consists of several elements, the most important ones are mentioned in order of use and the utility they perform.

Machine head

It is in charge of expelling the paper pulp in a thin layer on the cloth of the paper machine.

It is an elongated box, inside which the paste circulates. At its lower end, it has an opening along its length through which the paste film comes out. The width of this opening is controlled with lips, which, as their distance from each other increases, drop more or less. By controlling the output of paste from the lips, different properties of the formed sheet are obtained.

When leaving the lips, it falls directly on the machine cloth, this at its beginning, it is given a horizontal movement to mitigate a pronounced sense of the grain.

When the fibers fall, they tend to be placed in a position parallel to the movement of the cloth. If this is not partially eliminated, the paper will have a series of unsuitable characteristics, such as less dimensional stability (when the paper gets wet, the cellulose will swells, if all the fibers go in the same direction, they will swell more longitudinally than transversely), greater tearing (less united fibers).

A simple experiment to discover the direction of the fiber: take a sheet of newspaper (they have a very marked direction), tear it (without scissors, use your hands), first in the direction of the printed letters and then in the opposite direction, it can be seen that an almost straight line comes out in one direction, while in the other it is difficult to achieve.

In other high quality papers this difference is almost imperceptible, more complicated tests have to be carried out (stiffness for example).

Fabric

It is a very fine mesh where the pulp is placed and the dewatering and drying begins.

The first part of drying is by gravity, the water falls through the fabric and the fibers are retained in the upper part.

Afterwards, the excess water does not drain on its own, so you have to help it with various elements.

- Foils

Some pieces, generally plastic, that are placed in the lower part of the canvas. They have a slight angle of descent that, when in contact with the mesh, generates a certain vacuum.

- Vacuum foils

The same as foils, but they also absorb water using vacuum pumps.

- Dandy.

A large hollow roller, the exterior of which is covered with mesh. It is placed on top of the canvas in direct contact with the paper. Using pressure and, in some cases, vacuum pumps, it squeezes out the water.

It can also have a series of drawings in relief, which when pressed on the wet paper creates the watermarks. It is possible to see watermarks if, for example, a bank note is held up to the light.

By removing most of the water, the paper begins to have consistency and is placed in the section of presses and dryers.

Press and dryers

Once the paper has acquired consistency, as much moisture as possible must be removed. This stage uses pressure and heat.

Pressure is given by pairs of rubber-coated rollers; Between the rollers and the sheet of paper runs a felt strip that absorbs the water drained by the pressure of the roller.

The pressed paper web is passed through a series of hollow rollers through which steam at high temperatures circulates. To do this, it is accompanied by a felt blanket that prevents the sheet from separating from the cylinder, helping drying and guiding the sheet through them.

Kitchen

It is a separate process from paper manufacturing in which products are made to be applied to the surface of the paper to modify aspects of the final product. Then another series of presses continues to finish drying.

This product applied in the paper machine is called precoated. Then the paper can be taken to the coating machine to be coated applied which together with an application of pressure and heat gives the paper a shine.

Smooth and calenders

Once dry, the fibers have joined together finally becoming what we consider paper. On some occasions, a very shiny paper is required, or with a special smoothness; this is achieved by pressing between two rollers called smooth. The calenders have several metal rollers placed one on top of the other, some heated by steam.

Another application of the smooth ones is to modify the caliber or thickness of the paper by means of pressure.

Pope

Finally, the manufactured paper is rolled into large reels for later use. It is a cooling cylinder with water inlet and outlet for proper rolling.

Manipulated

- Rewinding

The paper machine delivers a continuous sheet of fixed width and with defects. In a rewinding stage, the defects are eliminated and the sheet is cut to length according to the needs of the users. The large coils obtained in pope are made into smaller, easier to handle finished coils.

- Court

The transformation of paper reels into cut paper is done in a machine called a cutter.

Once the paper is cut, it is separated into packages:

- Row: 500 leaves

- Average cream: 250 leaves

- Fourth: 125 leaves

- Fifth: 100 leaves.

These measurements are given because in the past the paper was counted by hand. The sheets were separated five by five (finger = 5 sheets) equivalent to a notebook, with each five notebooks of paper a hand was formed. (hand = 25 sheets), and twenty hands of paper made a ream.

Formats

To make printing easier and to save on paper costs, there are a series of rules on the format of paper.

In most European countries, the UNE standard (an adaptation of the DIN standard).

The most common formats are:

- Standard DIN Serie A

More information about paper formats.

Recycling

Background

Although paper was once obtained from other plants (including hemp from which high-quality cellulose is extracted), most paper is made from trees. To make one kilogram of conventional paper, one hundred liters of water are used.[citation required]

With paper and cardboard are manufactured:

- Paper bags for various uses.

- Cardboard boxes for various uses.

- Corrugated cardboard boxes.

- Cardboard and cardboard banners for pastries and for beverage packages.

- Paper for printing presses, offices and many other types.

In the world, the industry consumes around four billion trees each year, mainly pine and eucalyptus. Modern pulping techniques use very specific species of these trees.

Consumption of paper and cardboard in Argentina reaches 42 kg per person per year; in the United States, 300 kg per person per year, and in China and India 3 kg per person per year.

In Chile, between four hundred and five hundred thousand tons of paper are produced per year and around 47% is recovered. The pulp and paper industry uses a third of the national wood production.

Recycling saves 25% of energy in the manufacturing process.

Paper and cardboard recycling

Waste paper can be shredded and recycled multiple times. However, in each cycle, 15-20% of the fibers become too small to be used. The paper industry recycles its own waste and that which it collects from other companies, such as packaging manufacturers and printers.

Paper and cardboard are collected, separated and then mixed with water to be turned into pulp. The lower quality pulp is used to make cardboard boxes. Impurities and some inks are removed from the best quality pulp to make recycled paper for printing and writing. In other cases, recycled fiber is mixed with new pulp to make paper products with a percentage of recycled material.

One of the industrial sectors that uses a large amount of waste material is the manufacture of paper and cardboard. In Chile, the Paper and Cardboard Manufacturing Company, CMPC, is the main buyer of this waste. In the beginning, the Papelera bought the material at its plant in Puente Alto. With the increase in commercialized volumes, the Papelera created a subsidiary company, SOREPA, which since 1972 is supplied, throughout the country, by independent collectors and intermediaries.

Other companies that carry out this work in this country are: Eco-lógica, Recupac S.A., Comercial Ecobas Ltda., Sociedad de Servicios Industriales Ltda., Reciclados Industriales Ltda. In addition, some collection centers have recently been incorporated and recycling companies (these generally come from groups of cardboard collectors), which use this structure to enter the wholesale market. As a result of this, the following have emerged: Ecores Ltda., Conchalí Solid Waste Collection Center, Santiago Centro Collection Center, among others.

Actions for consumers

The main thing is to buy products that are minimally wrapped.

It is possible to promote the reuse, reduction and recycling of boxes and other containers and packaging, as well as encourage community organizations, supermarkets, schools and stores, to install paper recycling programs and cardboard.

World production

| Position | Country | Production (in Mt) | Position | Country | Production (in Mt) | |

|---|---|---|---|---|---|---|

| 1 | United States | 80.8 | 11 | Brazil | 7.8 | |

| 2 | China | 37.9 | 12 | Indonesia | 7 | |

| 3 | Japan | 30.5 | 13 | United Kingdom | 6.5 | |

| 4 | Canada | 20.1 | 14 | Russia | 6.3 | |

| 5 | Germany | 19.3 | 15 | Spain | 5.4 | |

| 6 | Finland | 13,1 | 16 | Austria | 4.6 | |

| 7 | Sweden | 11,1 | 17 | India | 4,1 | |

| 8 | South Korea | 10.1 | 18 | Mexico | 4,1 | |

| 9 | France | 9.9 | 19 | Thailand | 3.4 | |

| 10 | Italy | 9.4 | 20 | Netherlands | 3.3 | |

| Source: Handelsblatt - Die Welt in Zahlen (2005) | ||||||

Technical characteristics

Depending on the use to which it is directed, it needs specific technical characteristics. To do this, the qualities of the paper are measured.

The most common are:

- Weight - Gramaje

- Weight in grams per surface unit (g/m2). It was previously measured by the weight of a resma, a dozen folds, each fold of the size of eight leaves, of the old folio size (215 mm x 315 mm). Currently, the cream has another value (500 leaves).

- Breaking length

- The amount of paper (in thousands of meters) needed to break a paper strip for its own weight is measured.

- Desgarro

- Resistance that offers the role following a tear.

- Strike resistance

- Resistance that offers paper to break by pressure on one of its faces.

- Rigidity

- Pressure resistance of a paper sample.

- Double folds

- Quantity of folds that supports a sample until its breakage.

- Porosity

- The amount of air that passes through a sample of paper is measured.

- Blancura

- Whiteness.

- Opacity

- It is the property of the paper that reduces or prevents the passage of light through the leaf. It's the opposite of transparency.

- Dimensional stability

- Basically dimensional stability refers to changes in size of a sheet of paper depending on the humidity conditions in the environment. This means that depending on the humidity the paper will tend to vary its size; it usually does in the direction of the fibers (fusiform) so it can be predicted approximately how it deforms.

- Ascension capillary

- Height in millimeters that reaches the water in a partially submerged sample.

- Planning

- Some of the changes listed above affect the planning of the paper, the latter is an important factor for the ophset printing.

Conservation

Paper is one of the main sources of information, as well as constituting the historical and cultural memory of civilizations, not only those who use it but also those who manufacture it. For this reason, it is necessary to take into account its conservation and adequate protection, since both what is embodied in it, as well as the support, are part of the documentary memory of humanity.

There are different factors, both intrinsic and extrinsic, that alter and deteriorate paper, so it is necessary to know the immediate conditions that surround it.

- Humidity and temperature

- Excessive humidity can lead to the presence of fungi, undulations and degradation of paper by hydrolysis, which can be aggravated if the temperature is high as it catalyzes the degradation reaction. Instead the low humidity higher temperatures makes paper fragile and brittle.

- Light

- Lights, whether solar or artificial, when breaking cellulose chains, can degrade the paper. It is usual to observe the damage in the discoloration of inks and colors.

- Plates

- It is easy to find pests and insects in conditions similar to those required for the appearance of mushrooms. The most common are book worms, silver fish, book lice, cockroaches and rodents.

- Acidity

- It weakens the role, causes acid hydrolysis, and makes it more rigid and fragile. It can be generated by atmospheric pollutants, impurities, paints, ferrogálic inks, adhesives, assembly papers or presence of materials that are not acid free. The papers most affected by acidity are those produced from 1860, since it is very likely that they have been made with unpurified wood pulp and glued with light and collophony.

- Mancha

- It is all undesired alteration of the original color, caused by external elements. They can be the product of dust or dirt, humidity, fungus attack, adhesive tapes and food among others.

- Foxing

- It is thus called the appearance of ochre to brown stains, whose origin is unknown. There are two hypotheses about their origin; the first suggests that they are the product of iron metal impurities on paper, while the other mentions that it is a biological attack by bacteria or fungi.

- Oxidation

- It is given slowly and progressively and is caused by breaks in the cellulose chain. It can be accelerated by the presence of high acidity and humidity and temperature or presence of ferrogálic inks.

- Deformations

- They are caused by excess humidity or mechanical action.

- Rotations

- There are three types of breakages: torn, broken by fold and cut. In the first two cases the fibers are not fragmented while in the cuts the fibers are selected.

- Alterations of graphic elements

- It is generated when the alteration of the elements embodied in the paper negatively affect the support. They can be identified as the chromatic deterioration of the dyes, diffusion of the dyes by generating halos or stains and pigment drags by mechanical means or by humidity.

- Ferrostal inks

- They are inks created from iron and tannins and are classified into three types. Balanced inks have a balanced proportion of iron and tannins so they are stable. Ink unbalanced to iron, the amount of iron is greater than that of tannins, are susceptible to corrosion which causes the complete degradation of paper. And the inks unbalanced to the tannins, which act as protection against oxidation but they acquire a yellow coffee tone and tend to discoloration.

Storage conditions are essential for proper paper preservation, so a relative humidity range of 40 to 55% and a temperature range of 18 to 23 °C are recommended. They should be stored flat, not folded, and in the presence of acid-free material.

Applications

Paper is used for many things. Apart from the most common (writing, printing...) there are a number of curious uses:

- For papyroflexia.

- Doors. Some low-quality doors consist of two wooden sheets in which inside are a bee-type cells, which give consistency, made of paper.

- Decorative as wood substitute. For example, in those of Oak in whose interior appears when broken sawdust and a layer with drawing simulating wooden veins. It's wallpaper and melamine (treatment that gives it a plastic look). It is also used to make decorative objects by overlaying layers of gummed pieces by giving it the desired shape, or by moulding it after converting it into pasta, techniques called mache paper or pesta card.

- Money (billetes). It is a complicated role to make, and very complicated to imitate. It is made with a large percentage of cotton paste, which gives it resistance (very long fibers). Special fibers that shine with ultraviolet light are added, and water marks are applied.

- The decorative wallpaper of paraments in interior architecture.

- In the sculpture, although it always had its place for the realization of certain figures, more or less artistic, for which the so-called stone cardboard is used, it has been integrated for the realization of those "most noble". The role has, against what could be assumed, a great strength and persistence in time.

- Within the restoration of works on paper and books, the hand-made Japanese paper is used in its various frames, this by the quality of its long and resistant fibers and that it is acid free.

Museums

The Capellades Paper Mill Museum, located in Capellades, province of Barcelona, Spain, is one of the most important museums in terms of the theme of paper. It is located in an old paper mill. Its collection includes traditional papermaking machinery and papers and documents from the 13th century. In the basement, where paper is still being made by hand, it shows the traditional paper-making process.

The Valencian Paper Museum, located in Bañeres, province of Alicante, Spain, exhibits the traditional process of making paper, illustrated with the objects used and models of old mills. It includes 1,300 booklets of rolling paper, watermarks and paper toys, as well as a specialized library.

The Swiss Museum of Paper, Writing and Printing, located in Basel, Switzerland, is dedicated to papermaking, printing and writing. It shows the ancient artisan techniques of making paper, printing and binding. The museum is located in a restored building that already functioned as a paper mill more than 500 years ago.

Contenido relacionado

Electronic microscope

Website colors

Active Server Pages