Monotype

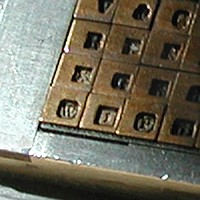

The monotype is a printing system developed by the company Monotype. It consists of a machine with a keyboard, as if it were a typewriter, with which the text is composed from a series of individual matrices of each character in which the same composition is cast in metal. Once printed, the lead is re-melted and is ready for the new composition.

Typographically, monotype is preferable to linotype, but it requires two separate machines with their respective operators, and is slower. It is a unique print variety; only a good reproduction of each sheet comes out. The artist draws on any smooth surface, using oil, watercolor or ink. Glass is generally used, but a sheet of polished copper or porcelain is also valid. The image can be created by simply painting it on the surface of the sheet or by means of an inversion process, it consists of covering the plate with a thin layer of pigments and gradually removing them with the fingers or with a brush until the image is formed. The paper is then applied to the sheet and the image is transferred, either by rubbing the back of the paper or using an etching press.

History

The Monotype typesetting machine, or monotype, was invented and patented in 1887 by Tolbert Lanston of Ohio, typed and cast single letters. It was developed along with the linotype (since it adds different typefaces and allows the use of large letters) for use in printing. same as the old hand cast types. It consists of two individual machines, each of which needs an operator. The keyboardist, who has a keyboard similar to that of a typewriter, produces a strip of paper punched with a code of holes. When approaching the end of each line, the operator decides how far to cut, whether in the same or heading or by word. Finally, the key that divides the excess space of the line by the number of spaces between the words is pressed, establishing the real distance between them (this is essential to facilitate reading).

The strip of paper is then fed back into the smelter (one operator can run two or more smelters) to receive the signal that sets the spaces between the words before composing the line. The foundry offers column after column of characters in completely massive metal, which are easily corrected, since each letter and each punctuation mark are separated; However, it is necessary to pay attention that this activity has been necessary since the invention of the printing press, because if only one line were to become pasted (when the typefaces fall off or become disordered), it would be necessary to reorganize it letter by letter.

This raises serious problems. If a linotype set page falls to the floor all that could happen is that the line is rearranged incorrectly, which would hardly go unnoticed by the proofreader. But if the same thing happened with a monotype set page, it would be necessary to recompose it completely and reread it. Each handcorrection of a single monotyped letter carries the risk of new errors.

Contenido relacionado

Control system

Document Object Model

DocBook