Mining

Mining is an economic activity in the primary sector when we refer to the extraction of minerals, and in the energy sector if we refer to the extraction of fossil fuels. It consists of the exploitation or extraction of minerals. Depending on the type of mineral to be extracted, the activity is divided into metallurgical mining (copper, gold, silver, aluminum, lead, iron, mercury, etc.) that are used as basic raw materials; Non-metallurgical mining or also called quarry and construction mining (clay, quartz, sapphire, emerald, granite, marble, mica, etc.) obtains construction materials and raw materials for jewelry and ornamentation, among other uses. Another type of mining is the extraction of energy or fuel minerals, used mainly to generate energy, such as oil, natural gas and coal or coal.

Mining is one of humanity's oldest activities, and since prehistoric times man has used various minerals to manufacture tools and weapons. It is an important industry, which has developed a series of techniques, studies and physical-chemical analyzes to improve the exploration and exploitation of deposits. For their part, mining companies or companies are in charge of carrying it out as an industry, whose competitiveness depends on the production of extracted mineral and its quality and quantity. To understand it better, the activity is divided into large, medium and small mining. However, in some countries there is a fourth category, artisanal.

Certain organizations, such as the World Bank, consider mining as one of the basic indicators of the possibilities of economic development of a locality, region or country. In 2021, mining was estimated to create $1.8 trillion in economic activity (or $1.8 billion). A 25-year-old miner can earn a salary of $200,000 per year, even without completing the high school. Most of the world's governments closely monitor or control the mining industry. Many laws seek to care for the environment and the safety of miners. In some countries, governments restrict or prohibit mining.

History

Prehistoric mining

Since the dawn of civilization, people have used stones, ceramics, and later metals taken from the earth's surface to make tools and weapons. A clear example of this is the high-quality flint found in northern France, Hungary and southern England, which was manipulated to create flint tools. The first mines of flint have been found in areas surrounded by of Crete, the most famous being Grime's Graves in England, dating from the Neolithic. Another of the rocks exploited at that time was the green shale, mined mainly in the Lake District in North West England.

The oldest known archaeological mine is the Lion's Cave in Swaziland, which, according to carbon-14 dating, is 43,000 years old. In this place, Paleolithic men they were digging for hematite with which they probably produced ocher pigments. According to the Swaziland National Trust Commission more than 1,200 tons of hematite, rich in specularite, were mined from the Lion's Cave during the prehistoric era.

Ancient Egypt

Mining in Ancient Egypt began during the first dynasties, where its inhabitants extracted malachite in Maadi, which was used for ornamentation and ceramics. Later, between 2613 and 2494 BC, and with the great projects construction sites, they were forced to trek through foreign lands such as Wadi Maghara, in order to secure minerals and other resources that did not exist in Egypt. Within these expeditions, they found quarries of turquoise and copper in Wadi Hammamat, Tura, Aswan and other Nubian sites, as well as in the Sinai Peninsula and at Timna.

For its part and according to the Greek historian Diodorus Siculus, Nubia had the largest and most extensive gold mines in the area. He mentioned that fire-settings called fire-setting were used with the aim of breaking the rock and thus releasing the gold, which was then ground to create a kind of powder, since it was more practical to melt it and so give it shape

Mining in Ancient Greece and Rome

With the arrival of the Greek and Roman civilizations, the mining industry in Europe had an important boom. During Ancient Greece, a wide variety of minerals and precious stones were mined for the construction of palaces, temples, and sculptures. The silver mines located in Lavrio greatly helped the economic boom of Athens, where an estimated 20,000 slaves worked. In addition, the need to obtain minerals, either for war or technological purposes, allowed the Greeks to exploit deposits of gold and silver in northern Thrace and copper, gold and iron in Cyprus, for example. Another Greek people, the Parians, complied important work in the extraction of white marble when they discovered rich deposits on the island of Thassos in 680 BC. C.

Many of the techniques used by the Greeks were adopted in Ancient Rome. However, the construction of numerous aqueducts allowed them to exploit various minerals on a large scale, since the water could be transported hundreds of kilometers until it reached the quarries themselves. The water was used for various purposes both to remove overburden and waste rock, called hydraulic mining, as well as for the comminution process and transport of simple machinery.

The Romans used hydraulic mining to explore veins, with an obsolete technique called hushing. This consisted of collecting the water from the aqueducts in large reservoirs and tanks that, at the moment of opening their doors, the enormous flow carried away all the layers of earth, exposing the bedrock and with it the possible vein of some mineral.. Afterwards, the rock was heated with fire-setting and then cooled with water jets, whose thermal shock ended up cracking it. This method is known to have been used by the Romans in cassiterite mines in Cornwall and lead deposits in the Pennines, both located in Great Britain. They were also used in Spain in the middle of 25 AD, to exploit large alluvial gold deposits located mainly in Las Médulas, where seven long aqueducts were built to take advantage of the local rivers. Many of the ancient Roman mining methods are now preserved in the British Museum and the National Museum of Wales.

Medieval Europe

Mining in the Middle Ages focused mainly on the extraction of copper, iron and other precious metals, which were initially extracted through open-cast mines —but shallow— and used to mint coins. Around the 14th century the demand for weapons, armor, stirrups and horseshoes greatly increased the extraction of iron. For example, medieval knights carried up to 45 kg of iron, not counting swords, spears, or other weapons. This reliance on iron for military purposes contributed to increased iron production and new extraction processes. However, this dependence on precious metals caused the silver crisis to occur in 1456, as the open pit mines had reached their depth limit and could not be drained with available technology.

In the mid-16th century, the need to exploit mineral deposits spread from Central Europe to England. In Continental Europe, all mining deposits belonged to the crown and that right was firmly maintained for hundreds of years; but in England only gold and silver mines were owned by the crown, by a court decision in 1568 and then by law in 1688. Therefore every Englishman whose land held reserves of some other mineral or coal, had a strong incentive to extract or lease such deposits and collect royalties from the workers of the eventual mine. In the mid-17th century century, the German, English, and Dutch capitals joined forces to finance the extraction and refining of some minerals. This union allowed hundreds of German technicians and many other skilled workers to create, in 1642, a colony of about 4,000 foreigners around the copper mines at Keswick.

The power of water and gunpowder was widely used during Medieval Europe. On the one hand, the water mills were used to crush and lift the ore from the shafts, and to ventilate the galleries through huge bellows. While gunpowder was used to blast rocks and earth, with the idea of loosening and revealing the veins of a mineral. This process was much more effective and faster than fire-setting, allowing the extraction of other minerals. As a matter of fact, gunpowder was first used in mining at Selmecbánya in the Kingdom of Hungary, in 1627.

The adoption of agricultural innovations, such as the iron plow, and the increasing use of metals as construction materials, were a driving force for the growth of iron mining in those years. In addition, new inventions such as the drag, a device that was driven by animals and that used the same principles of threshing, made it possible to more easily pulverize the recently extracted ore.

Much of the knowledge we have today about medieval mining comes from books, such as Vannoccio Biringuccio's De la Pirotechnia (1540) and perhaps the most important De re metallica by Georgius Agricola (1556), detailing the different extractive methods carried out in the mines of Germany and Saxony. One of the main problems that medieval miners had to face, and which Agricola gives quite a few details about, was the removal of water from the shafts. As the miners dug deeper and deeper in order to find new veins, the floods from groundwater became greater and greater. That is why the invention of mechanical or animal-driven pumps made the mining industry more efficient and prosperous.

Classical Philippine Civilization

Mining in the Philippines began around 1000 BC, with the earliest miners mining gold, silver, copper, and iron. The manufacture of jewelry, gold ingots, calombigas, earrings and other household artifacts such as daggers, plates, ornaments and teeth plating made with gold, were transmitted from ancient times and adopted by the following generations. In the work Tantric elements in pre-hispanic Philippines gold art by Laszlo Legeza, it is mentioned that some pieces of gold jewelry from the ancient kingdom of Butuan (centuries VIII to XV AD) found their way to Egypt, where they were mistaken by later European collectors for local jewelry. In addition, according to Italian explorer Antonio Pigafetta, the people of Mindoro possessed great skill in mixing gold with other metals, which gave it a perfect and natural appearance, and which could even fool the m best of silversmiths Finally, the native Filipinos were known for their belts, necklaces, bracelets, and rings made of precious stones such as carnelian, agate, and pearls.

Mining in America

Copper mines have also been found on the American continent, the exploitation of which began hundreds of years ago. Some of them have been discovered in Lake Superior in North America, where the clearing that comes from colonial times is still preserved. However, and with subsequent studies, it was confirmed that the Amerindians had been extracting it for more than 5,000 years. with which they created tools, arrowheads and other artifacts that according to scientists established a large commercial network between the peoples. When the first settlers arrived in America they discovered several exploited mines of obsidian, flint and other minerals, which were impossible to transport them to Europe due to the complexity of the terrain. In addition, French colonists found quartz deposits in the Saskatchewan region as they moved into the center of what is now Canada.

Colonial mining was characterized by large gold and silver exploitations, mainly extracted from Central and South America, which were transported to Spain in galleons. On the other hand, and according to various scientists, turquoise was another of the minerals valued by the Amerindians, whose exploitation began around 700 AD in the Cerrillos Mining District in New Mexico, where it was estimated that more than 15,000 tons of rock were removed from Mount Chalchihuitl with stone tools alone, before 1700.

Since the XIX century, mining in the United States began to be more frequent, to the point that in 1872 approved the General Mining Law, whose objective was to regularize and promote mining operations. The expeditions to find possible exploitable deposits became an important factor in the colonial expansion of the west of said country, which with the subsequent help of the railway, originated several mining centers that over the years became cities.

Modern Period

With the arrival of the XX century, mining boomed in several countries around the world, for example in the United States States, where the extraction of copper, lead, coal and iron was promoted, in addition to gold and silver that began in the previous century. This policy led to states such as Montana, Utah, Arizona and Alaska becoming the main copper suppliers in the world. For its part, the mining industry in Canada grew much more slowly, due to limitations in transportation, capital and direct competition with its neighboring country. Yet his domestic politics allowed Ontario to be the leading producer of nickel, copper, and gold at the turn of the century.

In the middle of the 19th century Australia experienced one of the most important gold rushes, which during the 1850s positioned itself as the main producer of said mineral, covering 40% of the world market. The establishment of the Mount Morgan mine, which was mined for almost a hundred years, the Broken Hill deposits, one of the largest deposits of lead and zinc, and the iron mines at Iron Knob, greatly increased the capital of the country. Even so, and during the first half of the XX century, Australian industry suffered a great decrease in production, but it was reactivated in the mid-1950s. 1960. Currently, the oceanic country is still positioned as one of the main mineral producers.

Since the middle of the last century, multinational corporations, and in some cases state-owned companies, have created a globalized mining industry with a large participation from other countries such as Peru, Brazil, Chile and South Africa, among others. In addition to this, several governments have generated a series of policies for the care of the environment and the regularization of overexploitation. In addition, countries such as the United States and China have invested more capital in the exploration and exploitation of minerals that contain rare earths, to meet the demand for new technologies.

Mine development and life cycle

Current mining is made up of several stages; from the discovery of the deposit, through the exploitation, until finally the closure and post-closure of the mine. The first phase is the discovery of the deposit, which is carried out through prospecting and exploration, whose objective is to know and define the extension, location and value of the mineral. Once that is done and through statistical and mathematical calculations, the size and grade of the deposit is estimated and used to create the pre-feasibility study, which theoretically determines the economics of the deposit, the initial investment and possible key risks. The next step is the feasibility study, which assesses the economic feasibility, technical and financial risks, and the soundness of the project.

Both studies provide the mining company with as much information as possible about the deposit, with which they make the decision to invest or abandon the project. If the mineral deposit is economically viable, the mining company begins to plan how it is going to be extracted, the metallurgy, the amount of mineral that is going to be recovered, the possible buyers and the type of concentrate that is going to be obtained. It is also concerned with engineering, the costs of comminution and infrastructure, the legal and environmental requirements demanded by the mining institutes of each country, but above all, how to obtain the necessary capital to make the extraction of the mine work.

To access the mine of the deposit it is necessary to extract the material that does not have an economic interest, also known as gangue. In the vast majority of cases, the amount of gangue is double the mineral that is extracted during the entire life of the mine, therefore the company must consider its removal and placement of said residue. The establishment of the so-called tailings dams must have a detailed study of the geography of the place, to avoid possible environmental risks that may affect the fauna, flora and communities adjacent to the mine. Once the construction of the plant and the tailings dam are defined, the extraction and commercialization of the mineral begins. The functionality and duration of the mine depends on the amount of mineral that the deposit has, and if, over the years, its extraction continues to be economically profitable.

After several years of operation, the mining company must begin the closure and post-closure of the mine, the process of which is gradual and therefore can take a long time. According to the laws and mining codes of each country, the closure of the works can be definitive or, to a lesser extent, partial. The vast majority of nations with large-tonnage mining industries demand the total closure of the mine, which implies dismantling the plant facilities and closing the entrances of the mines that were exploited underground. This process can be accompanied by the reforestation of the place, in order to restore the geographical and environmental characteristics that existed prior to the start of operations.

Exploitation methods

There are two methods to exploit a mineral: open pit mining and underground mining, the former being the most common today. According to researcher H.L. Hartmann in his essay Introductory Mining Engineering, open pit mining produces 85% of the minerals extracted in the United States, of which 95% are metallic ores. open-pit mining is that of placer deposits or also called placer-type deposits, which consists of valuable minerals contained in river gravel, beach sand or sediments produced by alluvium, whose extraction process varies from time to time employees in open pit mines.

However, and on certain specific occasions, such as in the extraction of uranium and rare earths, there are unusual methods, such as in situ leaching. This new technique consists of creating holes from the surface to the respective deposit, but even so it is not considered as an open or underground method. In situ leaching requires minerals to be soluble in water, such as potassium, potassium chloride, sodium chloride, and sodium sulfate. Other minerals such as uranium and copper oxides need acid or carbonate solutions for their dissolution and subsequent extraction.

Open Pit Mining

Open-pit mining or also called surface mining is carried out by removing vegetation (stripping) and the upper layers of rock, in order to reach buried deposits. Surface mining can be divided into open pit mining —in our language known simply as a pit mine or open pit— which consists of the extraction of minerals through a huge pit in the ground, which it can even reach several kilometers in length; quarrying, identical to open pit mining, but used in deposits of rock, sand and clay; the strip mining or discoveries that are used in deposits that are are relatively close to the surface and that is carried out mainly in the extraction of coal and lignite; the mountaintop removal mining or also called mountaintop mining, which involves a topographic alteration to the top of the mountain where the deposit is located, mainly coal. Within open pit mining are placer deposits and the technique called landfill mining and reclamation (LFMR), which consists of extract already processed minerals from garbage in landfills.

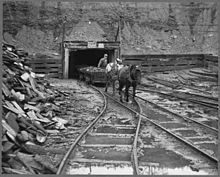

Underground Mining

Underground mining or on certain occasions called subsoil mining is carried out by building tunnels or galleries, with the aim of penetrating the rock in order to reach the deposits. This type of method is classified according to the form of access; drift mining (horizontally), slope mining (diagonally) and shaft mining (vertically), or according to the extraction technique; sinking or cascades. Within those of subsidence are the block caving, sublevel caving and panel caving, while by mansions they are divided into voids ( sublevel stoping and vertical crater retreat (VCR)), supported (cut & fill and shrinkage) and self-supported (open stopes and room & pillar).

Machinery

Throughout the useful life of a mine, different machinery is used, the choice of which will depend on the environmental conditions, the characteristics of the deposit and the geometry of the exploitation, and its specific requirements. Broadly speaking, the machinery used in mining is divided into three; loading equipment, transport equipment and mine service equipment. The purpose of the loading machinery is to load the recently blasted material and deposit it in transport equipment or directly in transfer shafts, in the case of underground mining. For its part, the objective of the transportation is to move the mineralized and/or sterile material from the deposit to the possible destinations, be it crushing, ore stock or waste dumps. Finally, the mine service teams carry out a specific task in the industry, which can be the transport of work material or personnel, earthworks and construction of roads, trenches, embankments and petriles, and drilling and loading of explosives., among others. Within this machinery are bulldozers, wheeldozers, motor graders, tank truck, backhoe, excavator, drilling jumbo, mixer truck, shocretera, roboshot and lifting equipment, among others.

Classification of machinery

Process

Once the ore is extracted it has to be processed according to certain protocols that have been analyzed for years. The science that studies this process is extractive metallurgy, which is an area of metallurgy that studies the extraction of precious metals from ores by chemical, mechanical, or electrolytic means. One of the studies of said science is mineral processing., which analyzes the mechanical means of crushing, grinding and washing, which allows the separation of metals with economic value from the gangue. Since the vast majority of metals are present in oxide and sulfide ores, it is necessary to process them by smelting or electrolytic reduction. The science that combines all these processes, be it mining, extractive metallurgy, and geological sciences, in addition to the economics of the deposit and the possible environmental damage, is called geometallurgy.

Productive circuit

The productive circuit, or also called the productive process, is defined as the stages through which a mineral undergoes until it becomes a marketable product. Below is a list of the main processes that are applied to a metallic mineral, of course, this list is general, since depending on the metal some threads can be included.

- Exploitation: Mineral extraction from the mine.

- Cargo and transport: Charge and transport of the mineral to the different delivery points (process plan, boots, etc.).

- Processing: Reduction of size by physical methods to release metal particles from the rock. Increased concentration of metals by physical-chemical methods.

- Foundry: Separation of the metals contained in the concentrates.

- Refinal: Purification of the metals product of the casting, for its industrial transformation.

- Marketing: Sale and purchase of purified metal.

- Recycling: After your useful life the material can be recycled, that is, to be recast.

Environmental impact of mining

Like many human activities, mining causes serious problems for the environment, due to its various mining and chemical processes. These effects can include erosion, sinkhole formation, loss of biodiversity, contamination of groundwater and surface water, as well as soil contamination. In some cases, deforestation around the mine is included as an additional factor, with the aim of creating enough space for the facilities necessary for its operation and waste storage. For its part, the contamination resulting from the leaks of chemical substances directly affects the local population, if it is not adequately controlled. An extreme case of environmental damage is the fire at the Centralia coal mine in Pennsylvania, which has been burning since 1962. through its tunnels located under the American town.

In many countries, mining companies are required to follow and comply with strict environmental protection codes in order to minimize their environmental impact and prevent potential problems for the adjacent community. These codes or regulations oblige mining companies to carry out an environmental impact assessment, develop environmental management plans, schedule mine closure, and prepare environmental monitoring during operation and after closure. For their part, if large companies need to seek international financing from institutions such as the Equator Principles and the International Finance Corporation, they must comply with another series of environmental regulations and, in addition, meet the criteria of socially responsible investment.

Beyond the requirements established by financial institutions or government agencies in each country, over the years large mining companies have self-regulated their effects on the environment through a series of codes of conduct. In 2001, nine of the large companies created the International Council on Mining and Metals (ICMM), whose objective is to mitigate damage to the environment, reduce, reuse and recycle inputs, integrate into the market concept sustainable development and contributing to the conservation of biodiversity, among other points. Currently, 23 mining and metals companies together with 35 national and regional mining associations make up this international council. In turn, some of them are active members in the creation of eco-efficiency policies of organizations such as the International Chamber of Commerce and the World Business Council for Sustainable Development.

Contamination of tailings

One of the main elements of contamination generated by the mining industry is that caused by tailings, which are classified as sterile or mineralized waste, with high levels of acids and chemicals, and whose storage is an important part of the planning process. leaf. In simple terms, a tailings is the gangue or material that is not economically viable from the extractive process of the mining operation, whose quantities vary according to the metal that is to be extracted. For example, a mineral that contains 20% metal will produce about 4 tons of tailings, while if it has only 1% metal, its extraction could generate up to 99 tons of tailings. In the case of gold mining, considered as one of the highest gold producers in the industry, only 5.3 grams of gold is mined for each tonne, meaning to achieve one tonne of Au, close to 200,000 tonnes of tailings will be produced.

To store the tailings, dams are built, which are engineering works made up of a retaining wall and a bucket, and which serve the same purpose as dams. Up to the year 2000, it was estimated that there were 3,500 dams in operation and that every year between two or three large-scale dams and 35 smaller ones were created. Poor planning and construction of the same can lead to severe risks for its environment, due to the failure of the retaining wall produced by the pressure of the tailings, the dragging of waste due to extensive rains, the seepage of its waters into the surroundings. and infiltration under the dam, lifting and dragging of fine material due to the wind, among others. The collapse of a dam causes critical contamination of surface and groundwater, biodiversity, soil and surrounding populations due to high concentrations of acid, mercury, iron, arsenic and lead, among other chemicals typical of mineral processing.

Throughout history there have been serious accidents caused by tailings spills, for example, in 1965 and after an earthquake the dam of the El Soldado Mine, located in the Nogales commune in Chile, collapsed, the contamination of which was it extended for hundreds of kilometers, completely burying the El Cobre mining camp and caused the death of 200 people. In 1996, at the Marcopper mine on the Philippine island of Marinduque, 1.6 million cubic meters contaminated 27 kilometers of the riverbank. Boac river and the coastal area. Its devastation meant the death of fish, river shrimp and pigs, the contamination of drinking water sources, the complete destruction of the Hinapulan barangay, the isolation of more than 20,000 people and the evacuation of a third of the villages in the Marinduque province.

For its part, on November 5, 2015, the worst tailings disaster in South America occurred when two dams at the Samarco Mineração S.A. mine, a company created by Vale S.A. and BHP Billiton, collapsed in the Bento Rodrigues subdistrict in the state of Minas Gerais in Brazil. In all, an estimated 55 million cubic meters of mud and iron ore waste killed the biodiversity of the Doce River, destroyed a village of 300 families, forced the shutdown of water supplies to more than 250,000 people, left 15 dead and 12 missing, and left hundreds of millions of dollars in material and natural losses. Even, months later, it was confirmed that their waste reached the Regencia beach in the state of Espírito Santo.

Mining industry

Mining as an industry occurs in several countries around the world, with London being the world capital of this activity. The British city is home to the world's largest trading market for non-ferrous metals and is the headquarters of major mining companies such as Rio Tinto Group, BHP Billiton and Anglo American. Other important markets are the New York Mercantile Exchange, where financial derivatives of some precious metals and energy products such as oil and natural gas are contracted. Finally, the Shanghai Stock Exchange is focused on those countries that export minerals to China, such as the nations located on the shores of the Pacific Ocean. In the case of the United States, mining is considered a great financial activity, without However, it is dominated by coal and non-metallic mining. However, in recent years various regulations have tried to reduce the importance of the activity in the country. In other Anglo-Saxon countries such as Canada and Australia, mining for decades has become a significant part of the internal economy.

In 2002, the OECD ranked Chile and Peru as the main mineral producers in South America and estimated that they had great economic potential in the coming years in this area. For its part, the industry in Africa is one of the most important and at the same time emerging, since despite the fact that its participation in the production of copper, lead and zinc is relatively minor, it is estimated that the continent has a significant percentage of the world's minerals, such as 40% of mineral reserves. gold, 60% cobalt and 90% platinum group minerals. In 2010, two of the four fastest growing economies in the world are mineral exporters and in turn African, Botswana and the Republic of Congo, while the other two are oil exporters. Regarding rare earth minerals, in 2013 China controlled 95% of the world production of these elements. For its part, Chile is the main exporter of iodine with 60 % of the production worldwide and also, it is the only global producer of nitrates or saltpeter.

Mining Classification

Each mineral-producing country uses different criteria to organize the industry's production and have a better understanding of its impact on the regional and national economy. The vast majority of countries use the criterion of the number of metric tons produced per year, although in some specific cases the capital of the mine, infrastructure or job creation are also included. Broadly speaking, the industry is classified into large, medium and small mining, however, in some countries such as Peru, a fourth classification is considered, artisanal mining. Below are the characteristics of the three main mining divisions and an example of the production figures required by the laws of Chile and Peru, considered by the OECD as the main mineral-producing countries in South America.

- Great mining: It is the one where mining companies have a large investment capital, a huge infrastructure—which can include a foundation plant, a port of embarkation or ferroviary connectivity of their own—, state-of-the-art technology, high monetary resources to ensure the safety and occupational health of workers, high levels of productivity, has large machinery, the alternative to exploiting large deposits and establishing inter-industrial links at the international level. Another important point in large mining is that all production is exported abroad. However, each country defines this type of mining by the number of metric tonnes produced per year, for example in the case of Chile it must produce over 3 000 000 tm/year, while in Peru it must be more than 5000 tonnes per day.

- Median mining: This classification has several similarities with the large mining, although its main differences are the amount of capital and that much of the mining companies are national. For its part, production is mainly intended for the domestic market. However, in Chile its production ranges from 100,000 to 3 000 tons per year, while in Peru its productive capacity does not exceed 5000 tons per day, to give an example.

- Small mining: It is the one where mineral reserves are small, it has less time of implementation of its operations and initial investment and has less infrastructure requirements, although it has higher employment ratios per unit of production. According to the analysis of developing countries, when small mining is located in economically backward regions, it stimulates income and distribution, the creation of new jobs and a better use of domestic resources, leading to a rapid increase in the standard of living of people. For its part, all of its production is marketed in the domestic market and its profits can be recycled in the region as a way of consumption or investment. In Chile it is defined as small mining to that which produces less than 100,000 tons per year, while in Peru it is that where its productive capacity reaches up to 350 tons per day.

Mining Companies

Mining companies are companies that carry out various activities to transform raw materials into specific products, whose competition depends on the production of extracted mineral and its quality and quantity. Many of the large companies are multinationals, private and also with capital open to the public in international markets. However, there are certain public or state companies with a large market share, such as the Chilean Codelco and the Indian National Mineral Development Corporation.

For their part, mining companies are classified into five categories according to the extraction and commercialization of the respective resources. These are oil and gas, coal mining, metallic minerals, non-metallic minerals and quarries, and mining support activities. Another form of classification is according to the net annual income that a company earns, categorizing itself from the following way:

- Great company: They are those where their annual net profits exceed 500 million dollars and have the financial capacity to develop an important mine under their own means.

- Medium companyThese are those where their annual net earnings range from $50 million to $500 million, whose financial capacity is not sufficient to develop an important mine by their own means, compelling them to seek financial support from national or international entities.

- Small company: These are those companies mainly intended for the exploration of a mineral, but they can also exploit at least. Their annual net gains should not exceed $50 million.

In 2012, the services firm PwC made a list of the main mining companies worldwide, where it also highlighted the number of companies by country. Canada ranked first with nine companies, followed by England with seven and the United States with five. It should be noted that BHP Billiton and Rio Tinto Group appear in both England and Australia, since they have capital from both countries. The same happens with Antofagasta plc, since it has capital from England and Chile.

Major mineral producers worldwide

In 2012, the United States Geological Survey (USGS) made a table with the largest countries producing gold, silver, copper and nickel worldwide. In turn, they were classified as developed, countries that have a track record in the field, emerging, countries that in recent decades have increased their participation worldwide, and developing, countries that have just started large-scale activity. Similarly, the strategic consultancy McKinsey & Company determined in 2012 that Latin America comprises 48% of copper production, 37% iron, 26% bauxite, 20% zinc and 16% nickel.

Note: Remember that the data reflected in the table were made in 2012, therefore the positions of the countries could change over the years. On the other hand, the dash (—) indicates that the country was not among the largest producers of a certain mineral until then.

Regulation

The governments of each country are the main regulators of the mining industry, which through legislative reforms seek to maintain harmony and stability in the productive sector. This occurs in the main mining countries, however, in African nations this regulation is still a pending issue due to the emerging nature of the activity. Since the beginning of the century XXI, mining companies provide slight benefits to local communities in terms of sustainability. This is partly due to the support and discussions offered in conjunction with the community and some NGOs, which have worked towards sustainable development, which includes transparency and revenue management and which can even be prolonged in time beyond the closure of the mine. In the early 2000s, this program was complied with by the World Bank, which included it in its requirements for mining projects financed by the entity. Despite this, the Fraser Institute —a think tank Canadian—exposed the precariousness of environmental protection laws in developing countries, as well as the voluntary efforts of companies to improve their environmental impact.

With the objective of knowing the monetary transactions between the private sector and governments, several mineral-producing countries created the Extractive Industry Transparency Initiative (EITI), which seeks to increase transparency about income received by the countries in which the mining or oil industries are based. In 2007, this initiative was implemented in all the countries that cooperate with the World Bank in the reform of the mining sector. However, criticism has cast doubt on two important points of the reform; whether or not to include small-scale mining and artisanal mining, and what to do about non-cash payments from companies to subnational governments. On the other hand, the disproportion of the industry's income in relation to the number of people it employs is also discussed. The issue of artisanal mining is a problem that manifests itself in the vast majority of EITI countries as a result of For example, Sierra Leone, the Republic of the Congo, the Democratic Republic of the Congo, Liberia and the Central African Republic, that is, this problem affects almost half of the countries in the initiative.

World Bank

The World Bank has been involved in mining since 1955, mainly through funds from the International Bank for Reconstruction and Development, and the Multilateral Investment Guarantee Agency, which offers country risk insurance. Between 1955 and 1990, about two billion dollars was provided to 50 mining projects, in terms of refurbishment and rehabilitation, mine construction, mineral processing, technical assistance and engineering. These projects have been the subject of criticism, particularly the Ferro Carajás project located in northwestern Brazil and which began construction in 1981, because it is located in a concession area of the Carajás national forest, a park protected by the Brazilian state.

In addition to financing mining projects, the bank prepares reports that seek to strengthen the sector, through codes and instructions that sometimes influence the laws of developing nations. However, some have been criticized for certain slogans, for example the pressure he has exerted in some countries to privatize all state-owned mining companies, which began in 1992 with his report The Strategy of African Mining. With the publication of the book Assistance for Minerals Sector Development and Reform in Member Countries in 1998, the bank approved the mandatory nature of the environmental impact assessment and attention to the concerns of the local population. In addition, it included new codes intended to encourage development through tax exemption, zero customs duties, reduced income taxes, and other related measures. The results of these codes were analyzed by a group from the University of Quebec, which they concluded that they promote foreign investment, but do not allow for high sustainable development. This observed negative correlation between natural resources and economic development is known as the resource curse. The United States, one of the richest countries in the world, operates mines in all its states or provinces, is the world leader in the production of various minerals, and generates 2.3 million jobs in mining and in the industries that supply mining.

Security

One of the important points of current mining activity is the safety of workers, which has achieved a fundamental consideration in national legislations from serious accidents that occurred especially in the XX. One of the most terrible was the Courrières catastrophe, which occurred in northern France on March 10, 1906, where 1,099 miners died and is considered the worst mining disaster in Europe. It was later surpassed by the Benxihu coal mine accident in China on April 26, 1942, which killed 1,549 miners. Despite the fact that mining safety is substantially better than in decades past, it is still there are still disasters worldwide. According to Chinese government data, about 5,000 people are killed in accidents each year, while other reports have suggested that the number is even higher than 20,000. produce a considerable number of deaths. Among the accidents that have occurred in recent years, the 2007 disaster at the Ulyanovskaya mine in Russia (108 deaths), the explosion at the Heilongjiang mine in China in 2009 (108 deaths) and the accident at the Upper Big Branch mine in the United States stand out. United States in 2010 (31 deaths).

The vast majority of fatal accidents occur in underground mines, which is why mine ventilation is a major problem for many companies. Poor mine ventilation causes exposure to noxious gases, heat and dust to cause injuries, occupational diseases and even death. The concentration of methane and other contaminants in the air below ground can be controlled by dilution (venting), capturing it before entering it (drainage), or by isolation (sealing or stopping). Poor control of noxious gases or high levels of rock, coal or silicon dust can cause suffocation and long-term diseases such as silicosis, asbestosis and pneumoconiosis (colloquially known in coal mining as black lung disease).).

Another point of consideration in underground mining is avoiding the ignition of methane gas, because if it occurs in a coal mine, it can start a coal dust fire and spread in all directions following the tunnels. For this reason, rock dusts such as limestone are used to reduce the chances of coal explosions, as well as limit the extent of coal explosions after ignition. It should be noted that a coal dust fire can also be caused by frictional heat or sparks from work equipment. Due to this, the work with said machinery is accompanied with water to cool the rock cutting work.

The use of rock drilling machinery in an underground mine causes high noise levels, which is the main source of gradual hearing loss, if proper personal hearing protection equipment is not used. The use of drilling rigs, together with the enclosed space in which underground miners work, can produce high levels of estimated power as high as 115 dB. However, drilling rigs are not the only machines that cause high noise levels, as that excavators, scoops, continuous transport equipment, trucks, front loaders and bulldozers are also considered the main sources of excessive noise in a mine. According to data provided by the Center for Disease Control and Prevention of the United States, the 90% of coal mine workers in the United States suffer from hearing loss by the age of 50, one of the highest levels compared to other types of jobs.

In recent decades, the development of new mine construction techniques and the mandatory use of personal protective equipment have reduced occupational accidents and the number of deaths in mines. However, landslides still represent up to 50% of the deaths produced in a mining operation.