Ergonomics

Ergonomics is the discipline that deals with the design of workplaces, tools, and tasks, so that they match the physiological, anatomical, and psychological characteristics and capabilities of the workers that will be seen. involved. It seeks the optimization of the three elements of the system (human-machine-environment), for which it develops methods of the person, the technique and the organization.

Derived from the Greek έργον (ergon, 'work') and νόμος (nomos, 'law'), the term denotes the science of work. It is a systematically oriented discipline, now applied to all aspects of human activity with machines.

The Council of the International Ergonomics Association (IEA), which brings together all scientific societies worldwide, established the following definition in 2000, which encompasses the interdisciplinarity that underlies this discipline:

Ergonomics (or human factors) is the scientific discipline related to the understanding of the interactions between humans and the elements of a system, and the profession that applies theory, principles, data and design methods to optimize human well-being and the entire performance of the system.

History and etymology

The foundations of the science of ergonomics appear to have been established within the context of Ancient Greek culture. A good deal of evidence indicates that the Greek civilization in the 5th century B.C. C. uses principles of ergonomics in the design of tools in their workplaces.

It can be found in Hippocrates' description of the design of tools and the way the workplace should be arranged for a surgeon (see Marmaras, Poulakakis, & Papakostopoulos, 1999). It is also true that there are archaeological records of the Egyptian dynasties, where it is observed that they made tools, household equipment, among others that illustrate the application of ergonomic principles. It is therefore questionable whether the claim by Marmaras, et al., about the origin of ergonomics, can be justified (IG Okorji, 2009). The term ergonomics, from the Greek Έργον, meaning "work", and Νόμος, meaning "natural laws", entered the modern lexicon, when Wojciech Jastrzębowski used the word in his article on 1857 «Rys ergonomji czyli Nauki o pracy, opartej na prawdach poczerpniętych z Nauki Przyrody» («The scheme of ergonomics, the science of work, based on the observations of the Natural Sciences»).

Later in the 19th century, Frederick Winslow Taylor pioneered Scientific Labor Management (Taylorism), method that proposes the way to find the optimal method to carry out a certain task. Taylor discovered that he could, for example, triple the amount of coal that workers were shoveling, gradually enlarging the size and reducing the weight of the coal shovels until the fastest rate of shoveling was achieved. Frank and Lillian Gilbreth extended Taylor's methods in the early 1900s to develop "Motion and Time Study." Their goal was to improve efficiency by eliminating unnecessary steps. By applying this approach, the Gilbreths reduced the number of masonry moves from 18 to 4.5, allowing masons to increase their productivity from 120 to 350 bricks per hour.

World War II marked the development of new weapons and complex machines, it also placed new demands on the cognition of operators. The machine operator's decision making, attention, situational awareness and hand-eye coordination became the key to the success or failure of a task. Fully operational aircraft, flown by the trained pilots, were observed to be in plane crashes. In 1943, Alphonse Chapanis, a US Army lieutenant, showed that this so-called "pilot error" could be greatly reduced, when the controls were replaced by more logical and less confusing layouts in the aircraft cockpit.

In the decades since the war, ergonomics has continued to flourish and diversify. The space age has created new human factors problems, such as weightlessness and G-forces. How far could the human body tolerate these environments in outer space, and what effects would they have on the mind and body? The dawn of the information age has been translated in the field of ergonomics as human-computer interaction (HCI).

The long-term coining of ergonomics, however, is widely attributed to British psychologist Hywel Murrell, at the 1949 meeting at the Admiralty in the UK, which led to the founding of the Ergonomics Society. He used it to encompass the studies in which they had participated.

Overview

- Ergonomics is defined as interactions between humans and the elements of a system.

- Its characteristics are physiological, physical, psychological and sociocultural.

- Its best known factors are man, machines and the environment.

- According to its domain, it is divided into cognitive, physical and organizational.

- Cognitive ergonomics studies mental processes.

- Physical ergonomics studies physical adaptability.

- Organizational ergonomics studies the optimization of psychotechnical systems.

The ergonomist's practice must have a broad understanding of the entire panorama of the discipline, taking into account the physical, cognitive, social, organizational, and environmental aspects, among other relevant factors. Ergonomists may work in one or several particular economic sectors or application domains. These application domains are not mutually exclusive and are constantly evolving. Some new ones are created, the old ones take new perspectives. Within the discipline, domains of specialization represent deep competencies in specific human attributes or characteristics of human interaction.

Ergonomics, as a multidisciplinary science, summons professionals from various areas: engineers, designers, doctors, nurses, kinesiologists, occupational therapists, psychologists, human resources specialists, architects, and many others.

Domains of ergonomics

Cognitive ergonomics

Cognitive (or as it is also called 'cognitive') ergonomics is concerned with how, and to what extent, mental processes such as perception, memory, reasoning, and motor response affect interactions between beings humans and the other elements of a system. Such as the ergonomic triad (human-machine-environment).

Issues relevant to you include: mental workload, mental fatigue, decision making, expert functioning, human-computer interaction (for example, Fitts' law), human reliability, job stress, training and qualification, insofar as these factors can be related to the design of the human-system interaction.

- Theory of information

Information in the everyday sense of the word, is the knowledge received about a specific fact. In the technical sense, information is the reduction of uncertainty regarding that fact. Information Theory is measured in bits of information, where one bit is the amount of information required to decide between two equally likely alternatives.

- Human Information Processing Model

Numerous models have been developed to explain how people process information. Many of these models consist of black boxes that represent the various stages of processing. The figure presents a generic model consisting of four major stages or components; perception, decision, and response selection, response execution, memory, and attention resources distributed in the different stages. The decision-making component, combined with working memory and long-term memory, can be considered the central processing unit, while the sensory store is a transitive memory located at the input stage. (Wickens, Giordon and Liu, 1997).

Physical ergonomics

Physical ergonomics deals with the anatomical, anthropometric, physiological, and biomechanical characteristics of the user as they relate to physical activity.

His most relevant topics include work postures, overexertion, manual material handling, repetitive movements, work-related musculotendinous injuries (MLT), job design, occupational health and safety.

Visual ergonomics

Visual ergonomics is a concept that is related to the search for the best visual performance of office workers. Visual ergonomics, as a domain within the branch of ergonomics, focuses on basic recommendations that must be met by those people who, in the performance of their activity, spend long hours working with screens and monitors. These recommendations include aspects such as the separation between the user and the screen, the need to repeatedly separate the view from the monitor and focus it on a distant point, or the benefits of repeated blinking that hydrates the corneal layers of the eye.

Organizational ergonomics

Organizational ergonomics, or macroergonomics, is concerned with the optimization of socio-technical systems, including their organizational structures, policies, and processes.

Relevant topics to this domain are psychosocial factors of work, communication, human resource management, task design, design of working hours and shift work, teamwork, participatory design, community ergonomics, cooperative work, new work paradigms, virtual organizations, teleworking and quality assurance.

Ergonomics and people

Ergonomics is a science that produces and integrates knowledge from the human sciences to adapt jobs, systems, products, environments, to mental and physical abilities; as well as the limitations of people. It seeks at the same time to safeguard safety, health and well-being while optimizing efficiency and behaviour. Failing to consider the principles of ergonomics will lead to various negative effects that —in general— are expressed in injuries, occupational disease, or deterioration in productivity and efficiency.

Ergonomics analyzes those aspects that encompass the artificial environment built by man, directly related to the acts and actions involved in all his activity, helping him to accommodate himself in a positive way to the environment and composition of the human body.

In all applications, its objective is common: it is about adapting products, tasks, tools, spaces and the environment in general to the capacity and needs of people, in a way that improves efficiency, safety and well-being of consumers, users or workers. From the user's perspective, it encompasses concepts of comfort, efficiency, productivity, and adequacy of an object.

Ergonomics is a science in itself, which forms its body of knowledge based on its experience and a broad base of information from other disciplines such as kinesiology, psychology, physiology, anthropometry, biomechanics, industrial engineering, design, physiotherapy, occupational therapy and many others.

The ergonomic approach consists of designing products and jobs in order to adapt them to the capacities, needs and limitations of people; the concept seeks to avoid that the solution to the problems of the workplace is the opposite way, that is, to demand repeated and numerous adaptations to the person to adapt to the job position.

The logic used by ergonomics is based on the axiom that people are more important than objects or production processes; therefore, in those cases in which any type of conflict of interest arises between people and things, the people must prevail.

As a principle, the design of products, tasks or jobs must be focused on the knowledge of the capacities and abilities, as well as the limitations of people (considered as users or workers, respectively), designing the elements that these used taking into account these characteristics.

Benefits of ergonomics

- Reduced risk of injury and accidents

- Decrease of errors / remake

- Ergonomic risk reduction

- Reduction of labour diseases

- Decrease in lost working days

- Decrease in Labour Ausentism

- Decrease in staff rotation

- Increased production rate

- Efficiency gain

- Increased productivity

- Increased production standards

- Increased good organizational climate

- Simplify tasks or activities

- Performance at work

Areas of ergonomics

Product design

Ergonomics is a very important factor when designing a product, since this will ensure its usability. By developing a product with the support of ergonomics you get:

- Maintenance facility: cleaning is facilitated, dirt accumulation is avoided, friction parts are reduced and lubrication is facilitated.

- Assimilationability: the learning curve is diminished, i.e., a lower demand is made for the previous abilities of the user. It requires less effort, fewer movements and less scopes.

- Inability: comfort conditions are established, immediate direct damages that the user may suffer are eliminated and risk factors are eliminated or reduced.

In order to design an effective ergonomic product, it is very important to carry out a prior study of the target audience, as well as create prototypes that allow validating the design.

Workstation design

Its application to the workplace has traditionally been the most frequent; although it is also very present in the design of products and in related fields such as home activities, leisure or sports. The design and adaptation of products and environments for people with functional limitations (elderly people, people with disabilities, etc.) is also another area of action of ergonomics.

All ergonomic design must consider the objectives of the organization, taking into account aspects such as production, efficiency, productivity, profitability, innovation and quality of service.

Product ergonomics

The objective of this scope is the consumers, users and the characteristics of the context in which the product is used. The study of ergonomic factors in products seeks to create or adapt products and elements for daily or specific use in such a way that they adapt to the characteristics of the people who are going to use them. In other words, ergonomics is transversal, but not to all products, but to the users of said product.

The ergonomic design of products tries to find that these are: efficient in their use, safe, that contribute to improve productivity, without generating pathologies in humans, that in the configuration of their shape indicate their mode of use and usage characteristics.

To achieve these objectives, ergonomics uses different techniques in the planning, design and evaluation phases. Some of these techniques are: functional and biomechanical analysis, anthropometric data of the target user segment of the design, cognitive ergonomics and analysis of the physiological behaviors of the body segments involved in the use of the product.

Strictly speaking, no object is ergonomic by itself, since the quality of such depends on the interaction with the individual. The characteristics of the object are not enough.

Universal Design Considerations

Most people experience some degree of physical limitation at some point in life, such as broken bones, sprained wrists, pregnancy, or aging. Others may live with a limitation or handicap every day. When considering product design, designers can recognize the special needs of different users, including people with disabilities. Issues related to accessibility for people with disabilities are becoming more prevalent, and employers may be required to make accommodations for these people in workplaces and other public spaces.

The Americans with Disabilities Act (ADA) does not specify requirements for your office furniture to accommodate people with disabilities. Therefore, it is incorrect to say that office furniture and products are "ADA compliant."

Designing with all people in mind is a principle known as universal design, which is important to keep in mind when designing products. In this section we will look at some universal design guidelines.

- Wheelchairs:

For standard wheelchairs, the seat height is 18" to 22", and the overall width is 22.5"-27.0". These values can help with furniture design, work surface height adjustment, and ease of wheelchair access. Persons who work seated in a wheelchair and may require reach considerations in the desk work area.

Some recommendations, regarding what dimensions are adequate to choose a wheelchair?; The first thing would be to sit in the wheelchair, adopt a correct posture and proceed to take the dimensions:

- Seat wound: 2.5 cm (two fingers) between the thighs and the side of the chair. Also 2.5 cm between thighs and armrests. If you use very wide clothes it is necessary to leave a little more space.

- Front edge of the seat: 3-5 cm (three fingers) between the seat and the back of the knee.

- Inclination back seat: 100o-110o; if adjustable can be better adapted to different activities.

Other dimensions to consider:

- Angle between arm and forearm: 120th with hand holding the highest part of the propulsor ring.

- Seat tilt: 1o-4o backwards; it is important to avoid slide forward and there is not much pressure on the sacral.

- Backup height: 2.5 cm below the scapula; backrest should not interfere when moving the arm back; for people with recent injuries or degenerative diseases the height adjustable backrests are more appropriate.

- Height of armrests: 2 cm above elbow with extended arm.

- Height of the footrest: 5 cm minimum, but it is recommended 10-13 cm to avoid stumbles. It is necessary to prevent the foot from slipping between the footrests.

Important facts for a wheelchair; chair tab:

A. seat width B. Back width C. Back-seat distance D. Footrest-seat distance E. Full width F. Full length

- Muletas, canes and walkers:

Some people, when they suffer an accident or a momentary disability, need the help of walking devices, such as crutches, canes or walkers. A minimum width of 36" from wall to wall, in a corridor or in a workplace is necessary to facilitate the mobility of these people. Studies have shown that 48" is the preferred aisle width for people using crutches, canes, or walkers. It is also important to keep these areas clear of obstacles to avoid the risk of a fall and further injury.

Objects that hinder the proper use and maneuverability of pedestrians must be moved and accommodated in a suitable place other than the corridors.

- Blades, handles and controls:

Knobs, handles and controls on products should be easy to use and intuitive. Some people are unable to get a firm grip on some types of doorknobs, while others may have prosthetic hands, which make it impossible to easily open doors. An L-shaped handle is preferable to a round one, as it allows access for a greater number of users.

Ergonomic design of workstations

The Gilbreths introduced manual labor design through motion study, in what is known as Therbligs, and the twenty-one principles of motion economy. The principles are classified into three basic groups:

- Use of the human body

- Settlement and conditions of the workplace

- Tool and equipment design

Something very important is that the principles are based on anatomical, biomechanical and physiological factors of the human body. These form the scientific basis of ergonomics and work design. The traditional principles of economy of motion have been expanded and are now known as principles and guidelines for work design:

- Manual work design

- Design of workstations, tools and equipment

- Design of the working environment

- Cognitive Work Design

- Ergonomic design of furniture.

Handwork Design

- Muscular bone system

The human body is capable of producing movements due to a complex system of muscles and bones, called the osseous-muscular system. There are three types of muscles in the human body: skeletal or striated muscles, attached to the bone; cardiac muscle, which is found in the heart, and soft muscle, such as that of the internal organs and the walls of the capillary vessels. It is necessary to know the conformation of the osseous-muscular system to delve into the analysis of manual work and develop applications to reduce the ergonomic risks present in the workplace.

| Force-speed ratio of the bone system |

- Achieving maximum muscle strength in the middle range of movement

The property of muscle that allows its use with a considerable decrease in muscle strength is known as the strength-length ratio. A task that requires considerable force must be performed in an optimal position. For example, the neutral or straight position provides the strongest grip for wrist movements. In elbow flexion, the best position would be with the elbow bent to a little more than 90°. In plantar flexion (such as pressing a pedal), again the optimal position is just over 90°.

- Achieving maximum muscle strength with slow movements

The force is sufficient only to move the mass of one segment of the body. This property is known as the force-velocity relationship and is especially important when dealing with heavy manual labor.

- Use of the time to help the worker whenever possible

Workstations should allow operators to leave the part in the delivery area while their hands are moving to pick up another component or tool and start a new cycle.

- Design tasks to optimize the capacity of human force

The capacity of human strength depends on three important factors:

- the type of force

- the muscle or body of movement that is used

- posture

There are three types of muscular effort, defined primarily by the way they are measured. The muscular efforts that result in body movements are the result of a dynamic force. In the case where the movement of the body is restricted, an isometric or static force is obtained. A third type of muscular strength capacity, psychophysical, has been defined for situations in which a demand for strength is required over a prolonged period of time.

- Use of large muscles for tasks that require strength

The force in the muscles is directly proportional to the size of the muscle, as defined by the cross-sectional area (87 psi (60N/cm²) for both men and women.) (Ikai and Fukunaga, 1968). For example, in heavy lifts the muscles of the legs and trunk should be used, and not weaker muscles.

- Stay 15% below the maximum voluntary force

Muscular fatigue is a very important criterion, but very little used in the adequate design of tasks for the human operator. The human body and muscle tissue rely on two primary types of energy sources, aerobic and anaerobic.

Because anaerobic metabolism can supply energy for only a short period, oxygen reaching muscle fibers via peripheral blood flow becomes critical in determining how long muscle contractions will last. For this reason, any activity that requires the use of force must be estimated at 15% below the maximum force, in order not to completely fatigue the muscle tissue and exhaust the operator. This relationship can be modeled by:

T = 1.2/(f - 0.15)0.618 − 1.21- T = resistance time (min)

- f = required force, expressed as fraction of the maximum isometric force

For example, a worker will be able to withstand a force level of 50% of maximum force for only about a minute:

T = 1.2/(0.5 − 0.15)0.618 − 1.21 = 1.09min- Use of intermittent, frequent and short work-reposive cycles

Whether performing repeated static contractions (such as holding a load with a flexed elbow) or a series of dynamic work elements (such as moving a lever with arms or legs), work and recovery should be assigned in short, frequent cycles (Micro Active Pauses). This is due, first of all, to a quick initial recovery period, which then tends to level off. Thus, most of the benefit is obtained in a relatively short period.

- Active Pauses

A program of Active Breaks within the worker's working hours improves motor skills, increases speed, coordination and, above all, aerobic capacity. Its objectives are:

- Activation of the respiratory and cardiovascular system

- Optimization of energy and oxygen supply

- Preparation of the neuromuscular system, of the passive and active locomotive

- Activation of psychovegetative systems for performance

Active pauses allow you to:

- Improve performance capacity

- Avoid, reduce or remove muscle imbalances

- Improved body posture

- Download joints and preserve them from discomfort

If the worker reaches full muscle (or whole body) fatigue, full recovery will require a longer time, perhaps several hours.

- Task design for most workers to perform

For a given group of muscles, there is a considerable range of strength in the normal healthy adult population, where the strongest is five to eight times stronger than the weakest. The difference is greater for the strength of the upper extremities and less in the lower ones. However, the primary cause of this effect is body size (ie total muscle mass) and not just gender; the average woman is considerably smaller and lighter than the average man. Furthermore, with the wide distribution for the strength of a given muscle, there are numerous women stronger than many men. In terms of age, muscle strength appears to peak around age 25 and then declines linearly from 20 to 25% by age 60. The decrease in strength is due to the reduction in muscle mass and the loss of muscle fibers.

- Use of little force for precise movements or fine motor control

Muscle contractions are initiated by neural innervation from the brain and spinal cord, which together form the central nervous system. The electrical activity of muscles, called an electromyogram (EMG), is a useful measure of local muscle activity. A typical motor neuron or nerve cell reaching the muscle from the central nervous system may have connections to several hundred muscle fibers. The innervation rate of the number of fibers per neuron ranges from less than 10 in the small muscles of the eye to more than 1000 in the large muscles and can vary considerably even within the same muscles. This functional arrangement is called a motor unit and has important implications for movement control.

- Accurate or fine-control movements should not be attempted right after heavy work

Lifting containers with heavy parts requires selecting the small motor units, as well as the large ones to generate the necessary muscular forces. During lifting and resupply, some motor units become fatigued and others are selected to compensate. When the operator finishes restocking the bins and returns to precise assembly work, some power units, including small precision ones, are not available. In other words, using large muscles in the first instance to perform heavy tasks at the work station will cause that when fine control movements are to be used to execute precision tasks, the muscle response will not be correct because it already exists. greater previous fatigue.

- The use of ballistic speed movements

Cross innervation of agonists and antagonists always occurs via spinal reflexes. This minimizes unnecessary conflicts between the muscles, as well as the consequent excessive energy expenditure. In other words, it is preferable to use movements that describe a ballistic trajectory or in the form of a parabola, from the center outwards and from the outside towards the center, than movements that are inaccurate and have sudden and abrupt changes.

- Start and finish movements with both hands at the same time

When the right hand works in its normal area to the right of the body and the left in his, to the left of the body, the feeling of balance tends to induce a rhythm in the performance of the operator, which leads him to the maximum productivity. The left hand on right-handed people can be just as effective as the right and should be used. The two hands should not be left idle, except during rest periods.

- Symmetric and simultaneous movements of both hands from and to the center of the body

It's natural for both hands to move in symmetrical patterns. Deviations from symmetry in a two-handed workstation lead to awkward operator movements. Many people are familiar with the difficulty of hitting the stomach with the left hand and rubbing the top of the head with the right. Another experiment that illustrates the difficulty of performing non-symmetrical operations is trying to draw a circle with your left hand and a square with your right.

- Use of the natural rhythm of the body

Spine reflexes that excite or inhibit muscles also lead to natural rhythms in the movement of body segments that can be compared to second-order mass-spring-damper systems, where body segments provide mass and muscle have internal resistance and damping.

Natural frequency is essential for the smooth and automatic performance of a task. Drillis (1963) studied a variety of very common manual tasks and suggested optimal work times, as follows:

- Last 60-78 metal polish per minute

- Courts 60 passes per minute

- Lever with hand 35 revolutions per minute

- Lever with leg 60-72 revolutions per minute

- Palear 14-17 pallets per minute

- Use of continuous curved movements

Due to the nature of the ligaments that join the segments of the body together (approximate to pin joints), it is easier for people to produce curved movements, that is, to pivot around a joint. Movements in a straight line that involve sharp and sudden changes in your direction require more time and are less precise. This law is easily demonstrated by moving either hand in a rectangular pattern, and then in a circular pattern of approximate magnitudes. Continuous curved movements do not require deceleration and are therefore faster per unit distance.

- Use of lower practical movements classification

This classification of movements finally ends up becoming a fundamental law of the economy of movements, to carry out an adequate study of methods

- Them finger movementsor first class movements, they are the fastest of the five types and are readily recognized because they are made by moving the fingers or fingers while the rest of the arm remains still. The typical movements of the fingers are to screw a nutshell, press the keys of a typewriter or take a small part.

- Them finger and wrist movements are made while the arm and arm are still, and are known as class movements two. Typical movements of fingers and wrists occur when placing a part on a device or assembling parts.

- Them finger movements, wrists and lower arm known as movements of class forearm three, and include those made by the arm below the elbow when the top does not move. As the forearm includes a strong muscle, those movements are not considered efficient because they are not fatigued. However, repetitive work with force of the extended arms can induce swelling, which is relieved by designing the work station so that the elbows are at 90° when performing the task.

- Them finger movements, wrist, lower part and upper arm known as movements of class four or shoulderand they may be used more than any other kind. This movement, for a given distance, takes much longer than the movements of the previous three classes. It is required to carry movements of parts that cannot be reached without extending the arm.

- Them class movements five include body movements, which are the most delayed. Body movements include ankle, knee and thigh, as well as trunk.

Class one moves require the least effort and time, while class five are considered the least efficient. Thus, the minor grading motion should always be used to do a proper job.

- Work with hands and feet at the same time

Since the hands are more capable than the feet, it wouldn't be smart to make the feet work while the hands are still. Devices such as foot pedals can often be arranged to allow clamping, ejecting, or feeding, freeing up hands for more useful work, thereby decreasing cycle time. When the hands move, the feet should not, since simultaneous movement of hands and feet is difficult; but the feet may be applying pressure to something like a pedal. In addition, the operator must be seated, since it is not easy to operate a foot pedal, and support the entire weight of the body on the other foot.

Design of work stations, tools and equipment

Methods Engineering recognizes these concepts by being able to adapt and adjust them to the operator as ergonomics. This approach helps achieve higher production and efficiency in operations and lower injury rates for operators.

- Anthropometry and design

The overriding guideline is to design the workplace to fit the majority of individuals in terms of the structural size of the human body. The science of measuring the human body is known as anthropometry, which uses caliper-like devices to determine structural dimensions, such as height, forearm length, and more.

- End design

Design for extremes implies that a specific feature is a limiting factor in determining the maximum and minimum value of a population variable to be adjusted, for example, the gaps, such as a door or the entrance to a storage tank, they should be designed for the maximum case, that is, for the height or shoulder width corresponding to the 95th percentile. In this way, 95% of men and almost all women will be able to pass through the clearing. The reach for things like a brake pedal or control knob is designed for the minimal individual, i.e. for legs or arms of women in the 5th percentile, so 95% of women and almost all men will have greater reach and they will be able to activate the pedal or control.

- Design to be adjustable

Design to fit is generally used for equipment or facilities that must accommodate a wide variety of individuals. Chairs, tables, desks, vehicle seats, a gear shifter, and tool holders are devices that fit a population of workers between the 5th percentile for women and the 95th percentile for men. It is obvious that designing to fit is the most convenient method of designing, but there is a trade-off with the cost of implementation.

- Design for the average

Design for the average is the least expensive but least preferred approach. Although there is no such thing as an individual with all average dimensions, there are certain situations in which it would be impractical or too costly to include fit possibilities for all characteristics. It is useful, practical, and cost-effective to build a one-to-one model of the equipment or facility being designed and have the users evaluate it.

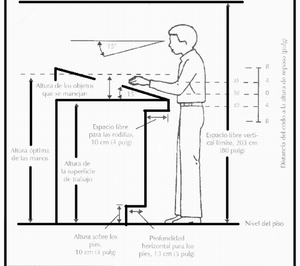

- Determine the height of the work surface according to the height of the elbow

The height of the work surface (with the worker either sitting or standing) should be determined by a comfortable working posture for the operator. In general, this means that the forearms are in the natural position down and the elbows are flexed at 90°, so that the arm is parallel to the ground. Elbow height becomes the proper operating or work surface height. If it is too high, the forearms curl up and cause shoulder fatigue, if it is too low, the neck or back sags, causing back fatigue.

- Adjust the height of the work surface according to the task performed

There are exceptions to this first principle. For heavy assembly with heavy lifting, it is more advantageous to lower the work surface up to 20 cm, to take advantage of the stronger muscles of the trunk. For a fine assembly that includes small visual details, it is more advantageous to raise the work surface 20 cm, to bring the details closer to the optimal 15° line of sight. Another alternative, perhaps it is better to tilt the surface around 15°, this way both principles are satisfied. However, the rounded parts have a tendency to roll off the surface.

These principles also apply to the sit-down station. A large proportion of tasks, such as writing or light assembly, are best done at resting elbow height. If the work requires the perception of fine detail, it may be necessary to elevate the work so that it is closer to the eyes. Sit-down stations must have adjustable chairs and footrests. Ideally, once the operator is comfortably seated with both feet on the ground, the work surface is positioned at the appropriate elbow height to accommodate operation. Thus, the work station also needs to be adjustable. Short operators whose feet do not reach the ground even after adjusting the seat should use a footrest that provides proper support.

- Provide a comfortable chair for the sitting operator

Sitting is important from the point of view of reducing both stress on the feet and overall energy expenditure. Since comfort is an individual response, it is quite difficult to set strict principles for good sitting. Furthermore, few chairs will accommodate the comfort of many possible sitting postures. It is very important to provide lumbar support through a protrusion in the back of the chair or with a lumbar cushion placed at belt height. provide easy adjustment for specific seat parameters. Height is most critical, where the ideal is determined by the person's popliteal height. A seat that is too high will uncomfortably compress your lower thighs, decrease your trunk angle, and again increase pressure on your discs. In addition, elbow pads are recommended to support the shoulders, arms, and footrests for shorter individuals. In general, chairs should have a smooth contour, padded seat, and covered in a breathable fabric to prevent moisture from sweat. A seat with cushion that is too soft restricts posture and can restrict circulation in the legs.

- Encourage flexibility in posture

The height of the workstation should be adjusted so that it is possible to work efficiently whether sitting or standing. The human body is not designed for prolonged periods of sitting. The discs between the vertebrae do not have a blood supply of their own, relying on pressure changes resulting from movement to receive nutrients and remove waste. Stiff posture also reduces blood flow to the muscles and induces fatigue and cramps in the muscles.

- Provide anti-fatigue tapes for workers who work standing

Different researchers report that more than a third of all workers have to work standing or walking for periods of more than four hours a day. Prolonged standing, defined as standing for more than two hours a day, has been linked to different health problems, such as:

- Lumbalgia (Drewezynski 1998, Hansen 1998, Redfern 1995)

- Pain in feet and legs (Drewezynski 1998, Hansen 1998, Redfern 1995)

- Plant Fascitis (Rys, 1994)

- Restriction of blood flow (Hansen 1998, Goonetilleke 1998)

- Swelling of legs and feet (Drewezynski 1998, Hansen 1998)

- Varicose veins (Drewezynski 1988)

- Increase in degenerative bone changes (osteoarthosis) in legs and knees (Manninen 2002)

- Preterm and low birth weight (Mozurkewich 2000, Hae E, 2002)

People who stand for 45 to 50% of their working day have foot and leg discomfort and those who stand for more than 25% of their day have low back pain (Rys 1994).

It's tiring to stand for long periods of time on a concrete floor. Operators should be provided with elastic anti-fatigue mats that allow small muscle contractions in the legs, which forces blood to move and prevent it from pooling in the lower extremities.

- Locate all tools and materials within the normal work area

In each movement a distance intervenes. The greater the distance, the greater the muscular effort, control, and time. Therefore, it is important to minimize distances. The normal working area of the right hand in the horizontal plane includes the area circumscribed by the forearm as it moves in an arc with a pivot at the elbow. This area represents the most convenient zone within which the hand performs movements with a normal expenditure of energy. The normal area of the left hand is established in a similar way. As the movements are made in the third dimension, as in the horizontal plane, the normal working area is also applied to the vertical plane.

- Fixed locations for all tools and materials that allow the best sequence

When driving a car, we are all familiar with how little time it takes to apply your foot to the brake. The reason is obvious: since the brake pedal has a fixed position, it does not take time to decide where it is located. The body instinctively responds by applying pressure to the area where the driver knows the brake pedal is. If its location were to change, the driver would need much more time to stop the car. Likewise, providing fixed locations for all tools and materials on the workstation eliminates, or at least minimizes, the little guesswork required to find and select the objects needed to get the job done.

- Use channel by gravity and surrender by dropping to reduce the times of reaching and moving

Gravity chutes allow for a clean work area, whether finished material is sent outside, rather than piled around it. A bin elevated off the work surface (so your hand can slide material under it will also decrease the time required to perform this task by 10-15%). Gravity chutes allow finished parts to be shipped within the normal area and eliminate the need for far movements.

- Optimal assembly of tools, controls and other components to minimize movements

The optimal arrangement depends on many characteristics, both human (strength, reach, senses) and the task (loads, repetition, orientation). It is obvious that not all factors can be optimized. The designer must establish priorities in the distribution of the work area. Once the location has been determined for a group of components, that is, the parts most frequently used for assembly, the principles of functionality and sequence of use must be taken into account. Functionality refers to the grouping of components according to the similarity of their function, for example, all fasteners in one area, all gaskets and rubber components in another area. It is very important to place the components or subassemblies in the order in which they are assembled, as this will go a long way in reducing wasted moves.

- Make multiple cuts when possible with the combination of two or more tools in a

The most efficient advanced production planning for manufacturing includes making multiple cuts with combination tools and simultaneous cutting with different tools. Of course, the type of work to be processed and the number of parts to be produced determine whether it is desirable to combine cuts, such as square and hex turret cuts.

- Use devices instead of holding hands

If either hand is used for holding during the processing of a part, then the hand is not doing useful work. A device can always be designed to hold work satisfactorily, and allow both hands to do useful work. The devices not only save processing time for parts, but also allow work to be held more accurately and firmly. Many times, foot-operated mechanisms allow both hands to perform productive work.

- Locate all control devices with greater accessibility and power capacity for the operator

Many machine tools and other devices are perfect in the mechanical sense, but they do not provide effective operation, because the designer of the installation did not take into account the different human factors. Handwheels, cranks, and levers must be sized and positioned to be operated by the operator with maximum skill and minimum fatigue. Controls that are used frequently should be positioned between elbow and shoulder height. Seated operators can apply maximum force to levers that are at elbow level; the operators stand, to the levers that have the height of the shoulder. The diameter of the steering wheels and handlebars depends on the torque to be applied and the riding position.

- Use shape, texture and size codes for controls

Shape codes, with geometric configurations of two or three dimensions, allow identification both by touch and visual. It is useful, especially in low light conditions, or in situations where redundancy or duplicate quality of identification is desired, to help minimize errors. Multi-rotation knobs are used for continuous control where the range of adjustment is greater than one full turn. Fractional Rotation knobs are used for continuous control with intervals less than one turn, while Positioning knobs are used for discrete adjustments.

- Use the size, displacement and resistance of appropriate controls

In their work assignments, operators use various types of controls and control designs all the time. The three parameters that have a large impact on performance are:

- Control size

- Reason control-responsive

- Control resistance when operating

A control that is too small or too large cannot be activated efficiently.

- Control-responsive reason (C/R) is defined as the amount of movement in a control divided between the amount of movement in the response. A low C/R ratio indicates high sensitivity, as in the thick setting of a micrometer. A high C/R ratio means low sensitivity, such as the fine micrometer setting. The global control movement depends on the combination of the primary travel time to achieve the approximate goal and the secondary adjustment time to achieve the exact target position accurately. The optimal C/R reason that minimizes this total movement depends on the type of control and the conditions of the task.

- Control resistance is important in terms of providing feedback to the operator. Ideally, it can be of two types: pure displacement without resistance, or pure force without displacement. The first one has the advantage of causing less fatigue, while the second one has the characteristics of the dead point, that is, the control returns to zero by dropping it. (Sanders and McCormick, 1993)

- Ensure proper compatibility between controls and screens

Compatibility is defined as the relationship between controls and displays that is consistent with human expectations. The basic principles include:

- Labour

- mapping and mapping

- feedback

so that the operator knows that the function has been achieved. For example, a door with a pull-open handle or a door with a push-open plate is good performance. Space mapping is observed in well-designed stoves. Movement compatibility is provided with direct action, scale readings that increase from left to right, and clockwise movements that increase setting. For circular displays, the best compatibility is achieved with a fixed scale and moving pointers or needles.

Warrick's principle is used on horizontal or vertical screens, which says that the closest pointers on the screen and the control movement in the same direction provide the best compatibility. (Sanders and McCormick, 1993)

- Noise dose

Noise dose that is above 80 dBA causes whoever listens to that amount to be affected by a partial dose. If said total daily exposure consists of several partial exposures to different noise levels, the partial doses are added to obtain a combined exposure:

D = 100 X (C1/T1 + C2/T2 + … + Cn/Tn) <= 100

Where: D = noise dose C = time spent under the effects of a specific noise level (h) T = time allowed under the effects of a specific noise level (h)

Total exposure to different noise levels cannot be exceeded at 100% dose.

Permitted noise exposures

| Duration per day (hours) | Sound level (dBA) |

| 8 | 90 |

| 6 | 92 |

| 4 | 95 |

| 3 | 97 |

| 2 | 100 |

| 1.5 | 102. |

| 1 | 105 |

| 0.5 | 110 |

| 0.25 or less | 115 |

When daily noise exposure is made up of two or more periods of exposure to noise of different levels, their combination effect should be considered instead of the independent effects of each of them. If the sum of the following fractions C1/T1 + C2/T2 + … + Cn/Tn exceeds unity, the combined exposure must be considered to exceed the maximum value. Cn indicates the total exposure time to a specific noise level, while Tn is equal to the total exposure time allowed during a working day. Exposure to impact noise must not exceed the peak sound pressure level of 140 dB.

Contenido relacionado

Otto Lilienthal

Invention

ISO 9000 standards