Elevator

An elevator or elevator is a vertical transportation system, designed to move people or objects between the different levels of a building or structure. It is made up of mechanical, electrical and electronic parts that work together to make it work.

According to its method of operation, there are two types: the electromechanical elevator and the hydraulic or oleodynamic elevator.

History

The first reference to an elevator appears in the works of the Roman architect Vitruvius, who maintains that Archimedes (ca. 287 BC – ca. 212 BC) had probably built the first elevator in the year 236 to. C. Literary sources from later times mention elevators composed of cabins supported with hemp rope and powered by hand or by animals. It is estimated that elevators of this type were installed in a monastery in Sinai, Egypt.

Around the year 1000, in the Book of Secrets written by Ibn Khalaf al-Muradi, from Islamic Spain, the use of an elevator as a lifting device is described, in order to raise a great weight to hit and destroy a fortress.

In the 17th century, there were prototype elevators in some English and French palatial buildings.

Ancient and medieval elevators used traction systems based on the crane mechanism. The invention of another system based on the screw drive was perhaps the most important step in elevator technology since antiquity, ultimately leading to the creation of modern passenger elevators. The first model was built by Ivan Kulibin and installed in the Winter Palace in 1793, while several years later another Kulibin elevator was installed in Archangel, near Moscow. In 1823, an "elevator cabin" in London.

In 1851, Waterman invented the first prototype forklift. It was a simple platform attached to a cable, to raise and lower goods and people.

As taller buildings were built, people became less inclined to climb long stairs. Department stores began to prosper, and the need arose for a device that would move customers from one floor to another with minimal effort.

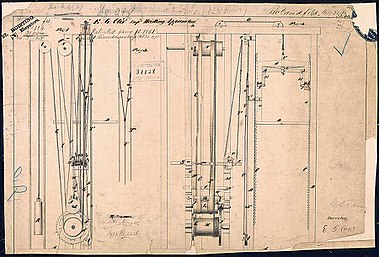

The elevator inspired the American from Vermont, Elisha G. Otis, to invent an elevator with a toothed system, which allowed it to cushion the fall of the elevator in case the support cable was cut. It was the first demonstration of a safety system for passenger elevators.

Oddly enough, Elisha Otis's talent as a designer was discovered while working as a master mechanic at a bed frame factory in Albany, New York. She invented various labor-saving devices, and so she was sent to Yonkers (New York), where she could better utilize her aptitude. There she designed and built this first elevator with an automatic safety mechanism in case there was a fault in the cable. In 1853 he had already established his own business to manufacture elevators, the Otis Elevator Company, which still exists today and is the largest elevator company in the world, having installed 2.5 million elevators and escalators all over the planet.. The following year Otis demonstrated this invention at an exhibition held in New York.

On August 30, 1957, an automatic door system was applied to passenger elevators, which made it possible to dispense with manually operated doors.

Another type of elevator is known as paternoster; It consists of a series of open booths, with limited capacity, that move slowly through two adjoining shafts. The cabins go up through one and, when they reach the top, they change to the other hole through which they go down in a continuous cycle, without stopping. Passengers get on and off as they go. It was very practical in places with a lot of movement of people between floors, although it had security problems, which is why it was replaced by escalators, which are much safer.

Elevators around the world

Businesses soon realized the potential of the invention, and in 1857 the first passenger elevator was installed in a department store located on Broadway Avenue, at the corner of Broome Street, in New York City, United States. Powered by steam, this elevator went up five floors in less than a minute. Back then, that was fast. In contrast to that, today the elevators in one of the tallest buildings in the world, the Willis Tower, in Chicago, go up 412 meters in less than a minute. Today, the tallest building in the world, the Burj Khalifa Tower in Dubai, 828 m high, it has elevators from the Otis Elevator Company that go up the longest distance in the world: 504 meters; It also has the highest elevator access in the world: 638 meters; and the fastest double cabin elevator in the world: 10 meters per second.

Constituent elements of an elevator

Cabin

The car is the basic element of the elevator system. It is made up of two parts: the frame or chassis and the box or cabin, or by a self-supporting cabin.

Counterweight

Most elevators have a counterweight, which has a mass equal to that of the car, plus half the maximum authorized load, so that the motor does not have to move the entire mass of the car, but only a fraction. Because of this, an empty elevator weighs less than the counterweight. The counterweight is also driven by some guides. Its function is to balance the load to facilitate the work of the motor and not force it to function.

Tractor group in electro-dynamic elevators

Tractor groups for elevators are normally made up of a motor coupled to a speed reducer, on whose output shaft the grooved pulley that drags the cables by adhesion is mounted.

Parachute system

At the lower or upper ends of the cab frame, there is the parachute system, either instantaneous or progressive. This releases some wedges against the guides to brake the car in the event that it descends at a speed greater than that allowed by the governor, thus preventing the car from falling freely even if all the cables that hold it are cut. In modern elevators and according to the regulations of each country or region, it also brakes on the way up.

Sometimes, a braking system is also installed in the counterweight. For example, when under the floor of the pit there is an area where people pass through, such as a car park. If the counterweight, which can weigh 700 kg, were to fall in free fall, it could break the floor of the pit and injure people in the area below the lift.

Maneuvers control panel

Elevator systems are controlled by electronic systems, responsible for operating the direction of movement of the car and selecting the floors where it must stop.

In 1862 the Otis elevator company invented the first "memory" for groups of elevators, which allowed their automation and dispense with elevator operators.

Currently, elevator controls work with electronic microprocessors that, through artificial intelligence algorithms, determine the way to manage the response to call requests, coordinating the operation of the different teams.

The current control panels have an error information system, which in the event of a fault shows the error code on a screen so that the elevator mechanic knows what was the reason that the elevator stopped.

An elevator has multiple safety devices to avoid any risk of accidents and as soon as any device fails, the elevator is automatically stopped. Any elevator, no matter how old it may be, has contacts in: the exterior doors, cabin doors, cable break contact (currently they are no longer mounted), upper governor pulley release, lower governor pulley cable loosening, cabin wedge, etc. As soon as any of these contacts fails, the elevator will stop indicating the contact or device that has failed.

Safety devices

System safety is a key element in elevators. To maximize security, several specific devices are used:

Electromechanical interlocking of the doors

In the access to the floors, which makes it impossible to open all the access doors except the one on the floor where the car is stopped.

All the locks, one on each landing, have a strap or an arm with a wheel, which when pressed allows the door to be unlocked, and only when it is mechanically locked by means of the hook. double claw, the electrical contact of the interlock is closed, which allows power to reach the coils of the contactors, and movement of the elevator is allowed. There are two types of mechanisms that allow the exterior doors to be opened when the car arrives on the ground. In old elevators there is an element called an electrocam, which is responsible for pressing the door strap of the destination floor. This electric cam is retractable, that is, it travels with the car retracted so as not to press the straps of each floor through which it passes (which would allow the opening of each of the doors and the stopping of the elevator), so that only when the maneuver control indicates by means of an electrical signal that the car is at the relevant stop, the electro-cam expands and actuates the corresponding door strap. The reverse process occurs when the elevator is requested from another site: the electric cam retracts before departure and only expands upon reaching it. In modern elevators there are other types of mechanisms. If the exterior doors are automatic, that is, they open by themselves, one of the car leaves has a retractable skid installed that opens the exterior door at the same time that it opens the interior door of the cabin. If the exterior doors are manual or semi-automatic (they are opened by the person who is going to enter the elevator and they close on their own), the car doors incorporate a slider that pushes the pulley of the lock or interlocking lever to allow the door to be opened. Outer door.

Traction cable breakage or unbalance parachute (a. electro-dynamic)

There are instantaneous and also progressive ones, for high and medium speed elevators. It consists of a system of levers whose movement activates wedges or rollers that are located in a box next to the guides (wedge box). When the car falls or exceeds the nominal speed, the guides are bitten by the wedges or rollers and the car stops.

Speed limiter (a. electro-dynamic) (speed governor)

It is made up of two pulleys: one installed in the machine room and the other vertically aligned with the first one at the bottom of the shaft. Through both passes a steel cable whose ends are linked, one to a fixed point on the frame of the cabin, and the other to a system of levers whose end is at the top of the frame. The cable accompanies the cabin at all times and is completely independent of the traction cables, that is, it does not intervene in the fastening of the cabin and the counterweight. The cable stops abruptly in the upper pulley of the governor when the speed of said pulley (and therefore that of the cabin) exceeds 25% of the nominal speed. The limiting cable activates the system of levers, called a parachute. It also incorporates an electrical contact both in the cabin wedging mechanism and in the upper pulley that cuts the main series to prevent the motor from continuing to work once the cabin has been "nailed" to the guides by means of the wedging mechanism. This mechanism was patented by Rubén Lorenzo Curiel in 1853.

Limit switches

They stop feeding when the car passes the rising or falling ends.

Mechanical travel safety devices

The car of an electric elevator can never be crushed against the ceiling of the shaft since shortly after exceeding the end of the ascent run, the counterweight already rests on the spring of the pit and the traction pulley that moves the cables, lose traction. The same thing happens in a hydraulic elevator, but because of the size of the piston. A few centimeters after the cabin passes the upper limit switch, the piston rod cannot extend further since it stops inside the piston and at the stops of the guides.

Emergency stop device

Interrupts the manoeuvre, cuts power to the tractor group and engages the brake. Allows the elevator to stop leaving the car and floor controls without effect. It normally lets the cab down to the lowest stop. If we refer to STOP or PARADA, normally you must let the car stop at the next stop, both up and down. This emergency system can also be called a "Rescue-matic". In old elevators, pressing the PARADA or STOP button produced an instantaneous stoppage of the car, and the traveler could be trapped between two floors with no possibility of exit. In current models, this button has ceased to exist on the cab panels, leaving only the alarm button as an emergency device in the hands of the user.

Alarm bell

For passengers to use in an emergency. In current elevators it is connected to a telephone line from which assistance can be requested in case of being trapped.

- Operation: When an electric power supply cut occurs, the emergency lighting inside the cabin is automatically switched on, the electronic alarm continues to be in operation due to its own feeding with accumulators. When the supply is re-established, the relief light is switched off and the equipment automatically starts reloading.

Emergency light

Illuminates the cabin in case normal lighting is interrupted.

There must be an automatic recharging backup source that is capable of powering at least one one-watt lamp for one hour, in the event of a power cut for normal lighting. The emergency lighting must be connected automatically as soon as the normal lighting supply fails.

Load weighing system

In modern elevators, a device called a load scale is usually installed. The function of this element is to prevent the elevator from moving more weight than the maximum allowed, thus avoiding excessive wear on the traction group and brakes. There are several types of weighing system and currently all of them are digital, so they have a fairly high accuracy.

In old elevators to which a load weighing system wants to be adapted, a mechanism consisting of sensors that are adapted to the traction cables and a control unit that collects the information given by the sensors is usually used. This switchboard is in turn connected to the elevator inspection box, so the control panel knows at all times if the elevator has more weight than allowed.

In new elevators, the system is similar, but the sensors are placed between the floor of the car and the chassis, allowing for even greater accuracy.

The control panels have 3 different states as far as the load scale is concerned:

- Normal: The cabin has less weight than the maximum allowed, so all systems will work normally.

- Complete: The lift has reached the maximum weight allowed, so the manoeuvre box will allow the cabin to make the trip programmed, but will not allow anyone else to enter the cabin until one of the passengers or cargo goes down. In case of elevators with selective manoeuvre (the elevator is picking up passengers as it goes up or down), it will not stop on any floor until the state of the weighloads is normal again, that is, until someone or cargo leaves the cabin.

- Overload: The elevator will not allow any trip until any person or any lump leaves the cabin. In this case there is usually a bright and sound indication indicating the state of excess load. The doors won't close and the elevator won't move until it returns to the normal state.

Mechanisms

The construction and characteristics of the tractor groups and the motors with which they are equipped, vary according to the nominal speed of the elevator and the service they must provide.

Electric Traction Elevator

This is the name given to the suspension system made up of a cabin on one side, and a counterweight on the other, which are given a vertical movement using an electric motor. All this works with a system of vertical guides and consists of safety elements such as the damper located in the pit (lower part of the elevator shaft) and a mechanical speed limiter, which detects excess speed in the car to activate the system. parachute, which automatically stops the elevator in the event that this occurs.

The electric elevator is the most common for transporting people at low and high speed (greater than 0.8 m/s), elevators with high comfort requirements (hospitals, hotels) or elevators that serve more than 6 floors.

One speed

Traction groups with single-speed motors are only used for elevators with speeds no greater than 0.7 m/s. In general, they are installed in residential elevators with a maximum load of 300 kg or 4 people.

Its stop level is very imprecise and varies a lot with the load, it is even different going up and going down. In many countries, its installation for new elevators is prohibited due to its lack of precision when stopping.

Two speeds

The two-speed tractor groups have triphasic motors with switchable poles, which operate at fast speed and at slow speed depending on the connection of the poles. In this way, with a low leveling speed, braking is obtained with the minimum error (approximately 10 mm error) and a more comfortable ride.

These powertrains are currently being retired as they consume too much power and are somewhat noisy.

Frequency variation

Acceleration at start-up and deceleration before the brake activates are carried out by means of a frequency variator coupled to the control panel. The brake acts when the elevator is practically stationary, thus achieving leveling and comfort that even exceed those of the two-speed system.

Hydraulic or oleodynamic lift

In hydraulic elevators, the drive is achieved by means of a pump, coupled to an electric motor, which injects oil under pressure, through maneuvering and safety valves, from a tank to a cylinder, whose piston supports and pushes the cabin, to ascend. On the descent, the oil piston is allowed to empty by means of a valve with a high pressure loss so that it is done smoothly. In this way, the hydraulic elevator only consumes energy during the ascent. On the contrary, the energy consumed in the ascent is four times higher than that consumed by the electro-mechanical elevator, so the result is that, on average, they consume more or less double than these. This type of elevator does not have a counterweight.

The driving group performs the functions of the electric elevator traction group, and the cylinder with its piston converts the energy of the motor into movement.

The fluid used as a transmitter of movement works in an open circuit, so the installation requires an oil tank. The machinery and warehouse of this type of elevator can be housed anywhere, located at a distance of up to 12 meters from the shaft, which allows more possibilities to install this elevator in locations with limited space.

They are the safest, slowest and consume the most energy, although they are the most suitable for installing in buildings without elevators.

Elevator without machine room

The electric elevator without machine room or MRL (Machine Room Less) is currently becoming more widespread. The advantages from the architectural point of view are clear: the volume occupied by the machine room of a traditional execution disappears, saving the costs of the traditional machine room, being able to be used for other purposes or making it possible to reach it with the elevator to the terrace or highest floor where the machine room was previously located. In this type of elevators gearless motors with permanent magnets are usually used, actuated by means of a maneuver controlled by a frequency inverter, located in the upper part of the shaft on a bench directly fixed to the guides, which are anchored to each slab. With this, the loads are transferred to the pit instead of being transmitted to the walls of the shaft, thus avoiding vibrations and disturbances to the adjacent houses.

Twin Elevators (twins)

The German company ThyssenKrupp Elevator is the first elevator manufacturer to invent and implement a system of two cabins traveling independently in the same elevator shaft. Thanks to extraordinary engineering work and an advanced control system, with a high security concept, it is possible for the two cabins to operate independently, creating huge potential benefits for use in new installations and building retrofits.

The heart of the system is a destination selection control, capable of intelligently assigning calls from different floors to each elevator. When a user calls an elevator from the corridor, before the passenger enters there, he collects the information of the floor he is on and the one he is going to, and assigns him the most suitable elevator for his journey.

The main advantage of this system is that it increases the transport capacity of the elevators in the building, using a smaller volume of construction and space.

Maneuver algorithms

To achieve more efficient operation, the most modern elevator systems have a memory that stores call requests and attends to them, prioritizing requests that are in the direction of the car, according to different operating algorithms:

Descending Collective

The keypads placed in the corridors of the intermediate floors have a single button.

Upward: The elevator stops at all the floors marked from the car, but does not answer any floor calls, except for the highest floor above the last registered by the passengers. Once the car reaches the last floor whose call has been registered, and after a period of time without new orders, the elevator changes direction.

Downhill: The elevator stops at all the floors registered in the car and also responds to the call requests from the floors, which it assumes are going down, until it reaches the lower floor that has a service request. In the event that the elevator has a load weighing device, the elevator will not stop at the intermediate floors if the car has a full load.

Collective ascending-descending

The button panels located in the corridors of the intermediate floors have two buttons: one for requests to go up and the other to go down.

Upward: The elevator stops at all floors marked from the car and also at floor requests marked as going up, but not going down. Upon reaching the highest floor above the last registered by the passengers or from the landings, and after a period of time without new orders, the elevator changes direction.

Downhill: The elevator stops at all the floors registered in the car and also attends to the call requests from the floors going down but not those going up, until it reaches the lower floor that has a service request.

Coordination System

Modern elevators have advanced artificial intelligence systems with logical algorithms that maximize the performance of the equipment by coordinating the operations of each one, in order to speed up call handling and increase transport capacity.

This operating mode, called on battery, achieves maximum efficiency through indices that calculate the operating circumstances of each piece of equipment several times per second, deciding which of all of them has a more advantageous compared to the set to meet the call request.

The latest generation equipment uses a microprocessor especially to perform the coordination task, due to the large number of variables and real-time data that complex algorithms take into account.

How to brake an elevator in the event of an accident

In theory, a body that fell from 443 m high would fall at a speed of 320 km/h. But those elevators are equipped with security mechanisms.

The improvement of modern elevators had its origins in 1854, when the American engineer Elisha Graves Otis installed the first safety mechanism in a freight elevator, at the Crystal Palace exhibition in New York. Previously, elevators of this type were very unsafe: their cables frequently broke and sometimes fatal accidents occurred.

With a certain theatrical spirit, Otis demonstrated his elevator: he climbed in it, along with boxes, barrels and other loads; then he ordered the cable to be cut. On earlier forklifts, this would have been deadly. But the safety mechanism worked and the elevator stopped immediately.

Otis' secret? A stout spring attached to the top of the lift platform. As the platform was raised, the spring bowed and its ends did not contact the guide rails on each side. But when the cable was cut, the spring recovered its shape and its ends locked into the rails, thus preventing it from collapsing. In 1857, Otis installed the first passenger elevator, in a five-story building on Broadway, New York. The invention of the safety elevator was a decisive factor in the emergence of skyscrapers. Before the buildings were a maximum of six floors, since people were opposed to climbing too many stairs, because it was exhausting. The passenger elevator and iron frame construction techniques provided the means for high-rise buildings.

Modern elevators do not differ in essence from the Otis model. They consist of a cabin that is hoisted, by means of steel cables, by two guide rails, and also have a safety mechanism that prevents it from collapsing. The cables come out of the cabin and go to a pulley located in the upper part of the elevator hub, and which is driven by a motor. The cables are lowered by the force of a counterweight that runs on guide rails.

Speed limiter

A key component of the protection is the speed limiter, which is linked by a cable to the safety device mounted under the elevator car.

The limiter uses the speed, when it reaches a speed higher than the nominal speed of the elevator this device locks in turn and through friction pulls the cable and this activates the parachute system mounted on the bottom from the cabin, just before the speed limiter engages, an electrical contact is activated which sends a signal to the control to stop the equipment electrically. If this contact does not work, the speed limiter is activated, then we have two ways to stop the elevator one is mechanical by means of the parachute and another is electrical by means of electrical contacts. The first to activate is the electrical contact if it does not work it stops mechanically.

Axle elevator motion controller

The elevator has a tran shaft, or reinforced tran tracks which prevent the box from leaving its axis, providing greater safety and less repair effort for the operators of some elevators. The tran is an element of metal or iron reinforced with titanium or the same elements excentes of metal or iron.

If the car continues to accelerate, the governor pulls hard on its cable, which activates the safety mechanism. In some special mechanisms, rollers or cams with toothed edges are used, which fit into the guide rails and stop the car. Others use shims similar to automobile brake shoes. As such, the elevator is a safe means of transport that avoids the fatigue and inconvenience that currently involves going up and down stairs, this is also a very favorable means for the use of people with physical disabilities.

Regulations

Spain

In Spain, elevators are regulated by Royal Decree 2291/1985, of November 8, which approves the Regulations for Lifting and Maintenance Devices. In it, the general regulations have been separated from those other technical ones more affected by foreseeable progress, which are included in the Complementary Technical Instructions (ITC).

As of September 1, 2017, the much more updated and complete EN 81-20 and EN 81-50 standards come into force, thus annulling the previous regulations.

Maintenance

The maintenance of elevators according to regulations includes different coverages: Standard, Semi Risk and All Risk. During standard maintenance, which is considered the mandatory basic maintenance of an elevator, 5 fundamental points are addressed:

- Routine reviews.

- Repair breakdowns that have occurred and the worn-out parts are replenished.

- Cleaning, lubrication and greasing of the different parts of the elevator.

- Inspections as appropriate.

- Amendments that the law compels to introduce.

On the other hand, every 3 or 4 months it is mandatory to clean the pit, check the brake, control the oil level of the engines and machinery, check for possible leaks and cleaning services in the cabin and machine room.

A more thorough annual review is also necessary. Essential points that are reviewed in an elevator annually:

- Correct state of emergency light, operator and state of skating and tension of cables.

- The counterweight moorings, the cabin moorings, the parachute and the elevator joints.

- The cables, pulley, impellers, detectors, end of the race and switches or fixes and cabin insulation are also checked.

- Proof of the security parachute the elevators have. The good condition of the system is checked and a working test is performed.

Contenido relacionado

Complementary metal oxide semiconductor

Graphic card

Rectifier