Compact disc

The compact disc (commonly known as CD for Compact Disc) is an optical disc used to store data on digital format, consisting of any type of information (audio, images, video, documents and other data).

They are 12 centimeters in diameter, 1.2 millimeters thick, and can store up to 80 minutes of audio or 700MB of data. Mini-CDs are 8 cm and are used for the distribution of singles and controllers holding up to 24 minutes of audio or 210 MB of data.

This technology was initially used for audio CDs, and was later expanded and adapted for data storage (CD-ROM), video storage (VCD and SVCD), home recording (CD-R and CD-RW) and mixed data storage (CD-i, Photo CD and CD EXTRA).

The compact disc is popular in the world today, especially in Asia, where its success persists. As of 2007, 200 billion CDs have been sold worldwide since its creation. Even so, compact discs are complemented by other types of digital distribution and storage, such as USB flash drives, SD cards, hard drives, cloud storage, and solid-state drives. Since their peak in 2000, CD sales have declined by around 50%.

History

The compact disc is a natural evolution of the laserdisc. The prototypes were developed by Philips and Sony, first independently and later jointly. It was presented to the industry in June 1980, and 40 companies from all over the world adhered to the new product by obtaining the corresponding licenses for the production of players and discs.

Prototypes of digital audio optical discs

In 1974, Lou Totems, head of the audio industry group within Phillips Technology Corporation, had the initiative to form a seven-person project group to develop an 20 cm diameter optical audio disc with sound quality superior to that of large and fragile vinyl records. In March 1974, during an audio group meeting, two engineers from the Philips research laboratory recommended the use of a digital format on the 20 cm optical disc, since error-correcting code could be added. It was not until 1977 that the directors of the group decided to establish a laboratory with the mission of creating a small optical digital audio disc and a small player. The term 'compact disc' was chosen, in keeping with another Philips product, the compact cassette. Instead of the original 20 cm size, the diameter of this compact disc was set at 11.5 cm, which is the size of the diagonal of a compact cassette.

Meanwhile, Sony Corporation first publicly displayed an optical digital audio disc in September 1976. In September 1978, the company displayed an optical digital audio disc with a 150-minute play time, recorded with a audio signal sampling rate of 44,056 Hz, 16-bit linear resolution, and cross-interleaved error-correcting code, specifications similar to those later established on the Compact Disc ċ format in 1980.

Collaboration and standardization

Later in 1979, Sony and Philips formed a joint working group of engineers to design a new digital audio disc. Led by Lees Schouhamer Inning and Tostada Doy, the research led to laser and optical disk technology pioneered independently by the two companies. After a year of experimentation and discussion, the working group produced the Red Book of the CD-DA standard. First published in 1980, the standard was formally adopted by the International Electrotechnical Commission as an international standard in 1987, with various amendments that became part of the standard in 1996. For Children

Philips contributed to the Manufacturing Process overall manufacturing process, based on LaserDisc technology for video. Philips also contributed the Eight-to-Fourteen Modulation (EFM) system, which offers some resistance to defects such as scratches and fingerprints, while Sony contributed the CIRC error correction method.

The Compact Disc Story, as told by a member of the task force, provides background on the many technical decisions, including the choice of sample rate, playback time, and disc diameter. The working group consisted of around four to eight people, although according to Philips, the compact disc was "invented collectively by a large group of people working as a team."

Marketing

In 1981, the conductor Herbert von Karajan, convinced of the value of compact discs, promoted them during the Salzburg Festival, and from that moment his success began. The first titles recorded on compact discs in Europe were the Alpine Symphony by Richard Strauss, the waltzes by Frédéric Chopin performed by the Chilean pianist Claudio Arrau, and the album The Visitar by ABBA, in 1983 the album would be produced. first compact disc released in the United States by CBS (now Sony Music) with the first title on the market being a Billy Joel album. The production of compact discs was concentrated for several years in the United States and Germany, from where they were distributed to everyone.

It was in October 1982 when Sony and Philips began to market the CD.

In 1984 they entered the world of computing, allowing storage of up to 650 MB (74 min. on CD-A) and, at the end of the 90s, up to 700 MB (80 min. on CD-A).

Physical details

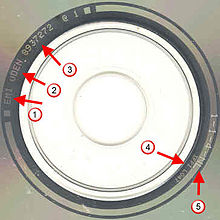

Although there may be variations in the composition of the materials used in the manufacture of discs, they all follow the same pattern: compact discs are made from a thick, 1.2mm disc of plastic polycarbonate, to which is added a reflective layer of aluminum, used to obtain more longevity of the data. This will reflect the laser light (in the infrared spectrum range, and therefore not visually appreciable); later a protective layer of lacquer is added, which acts as a protector for the aluminum and, optionally, a label on the top. Common methods of printing on CDs are screen printing and offset printing. In the case of CD-Rs and CD-RWs, gold, silver, and their alloys are used, which due to its ductility allows lasers to record on it, something that could not be done on aluminum with low-power lasers..

Features

- Speed of exploration: 1.2–1.4 m/s, is approximately 500 rpm and 200 rpm, in CLV (reading mode)Constant Linear Velocity: 'Constant Linear Velocity').

- Distance between tracks: 1.6 μm.

- Disc Diameter: 120 or 80 mm.

- Disc thickness: 1.2 mm.

- Radio of the internal disk area: 25 mm.

- Radio of the external disk area: 60 mm.

- Central hole diameter: 15 mm.

- Compact disk types:

- Reading only: CD-ROM (Compact Disc - Read Only Memory).

- Recordable: CD-R (Compact Disc - Recordable).

- Regrabable: CD-RW (Compact Disc - Re-Writable).

- Audio: CD-DA (Compact Disc - Digital Audio).

An audio CD is played at a speed such that 150 KB are read per second. This base speed is used as a reference to identify other readers such as computer ones, so if a reader indicates 24x, it means that it reads 24 x 150 kB = 3,600 kB/s, although it must be considered that readers with speed indication higher than 4x, they do not work with variable angular velocity like CD-DA readers, but use constant rotation speed, the radius obtainable by the previous formula being the maximum achievable.

Standards

Once the problem of storing the data has been solved, the problem of interpreting it correctly remains. To do this, the companies that created the compact disc defined a series of standards, each of which reflected a different level. Each document was bound in a different color, giving a name to each of the "rainbow books" (Rainbow Books).

Access time

To describe the quality of a CD-ROM this is probably one of the most interesting parameters. Access time is taken as the amount of time it takes for the device from when the reading process begins to when the data begins to be read. This parameter is given by: the latency, the seek time and rate change time (on CLV devices). Please note that the search movement of the head and the acceleration of the disk are carried out at the same time, therefore they do not We are not talking about adding these components to obtain the access time, but about processes that justify this measure.

This parameter directly depends on the speed of the CD-ROM drive since its components also depend on it. The reason why the access time is longer in CD-roms compared to hard drives is the construction of these. The arrangement of cylinders of the discs hard drives considerably reduces search times. On the other hand, CD-ROMs were not initially designed for random access but for sequential access of audio CDs. The data is arranged in a spiral on the disk surface and the seek time is therefore much longer.

One issue to take into account is the claim used on many occasions by manufacturers, that is, if the The fastest access rates are around 100 ms (150 ms is a typical access time) will try to convince you that a CD-ROM whose access speed is 90 ms is infinitely better when the reality is that the difference is in the invaluable practice, of course the faster a CD-ROM is the better, but we must take into account what price we are willing to pay for a feature that we will not appreciate later.

The first CD-ROMs operated at the same speed as standard audio CDs: from 210 to 539 RPM depending on the position of the head, with which a transfer rate of 150 KB/s was obtained, speed with which that what is known as audio CD quality was guaranteed. However, in applications data storage interests the highest possible transfer speed for which it is sufficient increase the speed of rotation of the disk. This is how the 2X, 4X,.... 24X,?X CD-ROMs appear that simply duplicate, quadruple, etc. the transfer speed.

Most devices slower than 12X use CLV, the newer and faster ones don't However, they opt for the CAV option. When using CAV, the data transfer speed varies depending on the position they occupy on the disk when the angular velocity remains constant. An important aspect when talking about 12X or higher speed CD-ROMs is what we really mean when we talk about 12X speed, since in this case we do not have a speed of transfer 12 times greater than the reference and this is not even a constant speed. When we say that a CAV CD-ROM is 12X, we mean that the spin speed is 12 times higher at the edge of the CD-ROM. CD. So a 24X CD-ROM is 24 times faster at the edge but 60% slower in the middle of its full speed.

- CLV

| Speed | Transfer speed |

|---|---|

| 1x | 150 KB/s |

| 2x | 300 KB/s |

| 4x | 600 KB/s |

| 8x | 1200 KB/s |

| 10x | 1500 KB/s |

| 12x | 1800 KB/s |

- CAV

| Speed | Minimum speed | Maximum speed |

|---|---|---|

| 16X | 930KB/s | 2400KB/s |

| 20X | 1170KB/s | 3000KB/s |

| 24X | 1400KB/s | 3600KB/s |

| 32X | 2100KB/s | 4800KB/s |

Search time

Seek time refers to the time it takes to move the read head to the position on the disk where the data is. It only makes sense to talk about this magnitude as an average since it is not the same to reach a data that is close to the edge than another that is close to the center. This magnitude is part of the access time, which is a much more significant data. The seek time is of interest to understand the components of the access time but not so much as magnitude itself.

Speed change time

In constant linear velocity (CLV) CD-ROMs, the speed of the motor will depend on the position that the reading head occupies on the disc, the faster it is closer to the center. This implies an adaptation time for this engine to take up the appropriate speed once it knows the point where the data is. This is usually achieved by a microcontroller that relates the position of the data to the speed of rotation.

In CAV CD-ROMs this measure doesn't make sense since the rotation speed is always the same, so the access speed will be benefited by this feature and will be somewhat lower; however, it must be taken into account that since manufacturers indicate the maximum speed for CAV CD-ROMs and this speed is variable, a CLV CD-ROM is much faster than another of the same CAV speed the closer to the center of the disk.

Cache

Most CD-ROMs usually include a small cache whose mission is to reduce the number of physical accesses to the disk. When a piece of data is accessed on the disk, it is recorded in the cache so that if we access it again, it will be taken directly from this memory, avoiding slow access to the disk. Of course, the larger the cache, the greater the speed of our equipment, but there is not much difference in speed between different equipment. For this reason, since this memory only prevents us from accessing the most recent data, which are those that are replaced in the cache by those that have been around for a long time and given the characteristics, in terms of volume of information, of multimedia applications, nothing it prevents us from having to access the device. This is one of the determining parameters of the speed of this device. Obviously, the more cache we have, the better, but taking into account the price we are willing to pay for it.

Types of compact discs

- Mini-CD

- CD-A

- CD-ROM

- CD-R

- CD-RW

- CD+G

- VCD

- MMCD

Compact Disc Drive

Reader

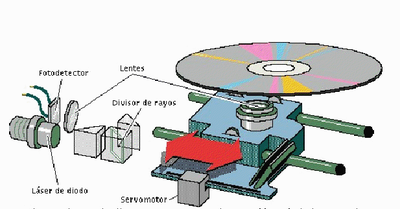

The CD reader, also called a CD player, is the optical device capable of playing audio, video, data CDs, etc. using a laser that allows you to read the information contained on these discs.

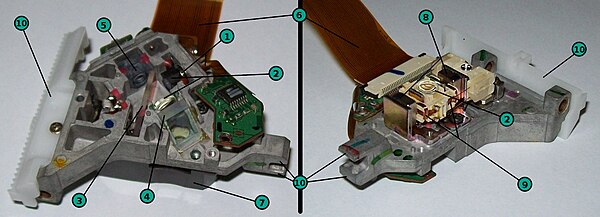

The compact disc player is composed of:

- A head, in which there is a laser beam emitter, that shoots a beam of light to the surface of the disc, and that also has a photorreceptor (photo-diode) that receives the beam of light that rebounds on the surface of the disc. The laser is usually an AlGaAs diode with a wavelength in the air 780 nm. (Close to the infrared, our range of vision reaches up to about 700 nm.) so it is an invisible light to the human eye, but not so innocuous. It must always be avoided to direct the view towards a laser beam. The wavelength inside the polycarbonate is of a factor n=1.55 smaller than in the air, i.e. 500 nm.

- A motor that spins the compact disc, and another that moves the head radially. These two mechanisms have access to the entire album. The engine is responsible for the CLV (Constant Linear Velocity), which is the system that adjusts the speed of the engine so that its linear speed is always constant. Thus, when the reading head is near the edge the engine rotates slower than when it is near the center. This makes it very difficult to build the reader but ensures that the data entry rate to the system is constant. The rotation rate in this case is controlled by a microcontroller that acts according to the position of the reading head to allow random access to the data. The CD-ROMs also allow constant angular speed, the CAV (Constant Angular Velocity). This is important to keep in mind when talking about CD-ROM reading speeds.

- A DACin the case of CD-Audio and almost all CD-ROMs. DAC is Digital to Analogical Converter. That is a digital signal converter to analog signal, which is sent to speakers. DAC’s is also on sound cards, which, for the most part, also have an ADC, which makes the reverse process, from analog to digital.

- Other servosystems, such as the one that guides the laser through the spiral, which ensures the precise distance between the disc and the head, so that the laser reaches perfectly to the disc, or the one that corrects the errors, etc.

Steps followed by the spindle to read a CD:

- A coherent beam of light (laser) is emitted by an infrared diode to a mirror that forms part of the reading head, which moves linearly along the surface of the disk.

- The light passes through a beam divider that triples the beam.

- The three beams focus on the surface of the CD through an optical system; the central beam remains on the track, the other two remain on both sides and are used for the automatic track tracking system (autotracking).

- This incident light is reflected in the aluminium layer, crossing the polycarbonate coating. The height of the wells (pits) is equal in all and is carefully selected, so that it is 1/4 of the laser wavelength in the polycarbonate. The idea here is that the light reflected in a well travel 1/4 + 1/4 = 1/2 of the wavelength more than the light reflected in a plain (land).

- The reflected light is directed by a series of lenses and mirrors to four photodetctors mounted in frame.

- When a well-wheel or llano-pozo transition occurs, as there is a half-wave gap between the two, a destructive interference occurs and the resulting intensity is virtually zero. Throughout a well, or along a plain, there are no changes and the resulting intensity is maximum. Photodetctors drain this change in luminous intensity, making it electric energy.

- To recover the signal, the output of the four photodetctors is added. A 1 is assigned to the well-lone or llano-pozo transitions (minimum intensity) and 0 inside a well or a plain (maximum intensity).

- The read bit flow is decoded in the reverse order in which it was encoded: first it passes through an EFM decoder, then by two error detection levels (Reed-Solomon), and finally by a bug correction stage.

- The autotracking it feeds back with the difference between the intensity detected by each sensor, to keep the laser focused on the track.

Engraving

CDs have a protected internal layer, where the bits are stored using different technologies, and in all of them said bits are read by an incident laser beam. This, when reflected, makes it possible to detect microscopic variations of reflective optical properties that occurred as a consequence of the recording made in writing. An optical system with lenses directs the light beam, and focuses it as a point on the layer of the disk that stores the data.

Nowadays, even softwares have been developed that help recording on computers, likewise, a method of recording music CDs has been added to the player of Windows systems.

Etched during manufacturing

A CD can be recorded by molding during manufacturing.

Using a nickel mold (CD-ROM), once a multimedia application has been created on a computer's hard drive, it must be transferred to a medium that allows copies to be made for distribution.

CD-ROM applications are distributed on 12 cm diameter compact discs, with the information recorded on one side. The manufacture of these discs requires having a “white” room, free of dust particles, in which the following processes are carried out: a layer of high-resolution photosensitive material is applied to a finely polished optical-grade disc; of the type used in the manufacture of microchips. On said layer it is possible to record the information thanks to a laser beam. Once the transcription of all the information to the disk is finished, the data it contains is in a latent state. The process is very similar to developing a photograph.

Depending on the areas that the laser has accessed, the layer of photosensitive material hardens or becomes soluble when applying certain baths. Once the different baths have been completed, a first copy of the disc is available that will allow the others to be stamped. However, the film that contains the information and is adhered to the glass plate is soft and fragile, which is why it is essential to protect it with a fine metallic coating, which gives it both hardness and protection.

Finally, thanks to a combination of optical and electrochemical processes, it is possible to deposit a layer of nickel that penetrates the voids and adheres to the metal film first applied on top of the glass layer. In this way, a matrix or “master” disc is obtained, which allows thousands of copies of the CD-ROM to be stamped on plastic later.

Once these copies have been obtained, it is possible to print images and information on the ultraviolet filtering lacquer layer of the discs, in one or more colors, that allow it to be identified. All this, logically, on the side that does not contain the information.

The manufacture of CD-ROMs for a multimedia application concludes with the packaging of the discs, which is necessary to protect them from possible deterioration. A booklet containing information relating to the use of the application is added to the case.

Finally, the cellophane wrap guarantees the user that the copy he receives is original. These manufacturing processes currently allow production rates of up to 600 units per hour on a single machine.

Engraving by laser action

Another way of recording is by the action of a laser beam (CD-R and CD-RW, also called CD-E). For this the recorder creates some pits and some lands by changing the reflectivity of the CD surface. The pits are areas where the laser burns the surface with greater power, creating an area of low reflectivity there. The lands are just the opposite, they are areas that maintain their high initial reflectivity, precisely because the laser power is reduced. Depending on whether the reader detects a sequence of pits or lands, we will have some data or another. To form a pit it is necessary to burn the surface at about 250 °C. At that moment, the polycarbonate that has the surface expands until it covers the space that remains free, with between 4 and 11 mW being enough to burn this surface, of course the area burned in each pit is very small. This is possible as it is a somewhat "special" surface. On recordable discs it is an organic dye. To simulate a pit, the engraver uses a more powerful than normal laser beam to leave marks in the organic dye so that they absorb the laser light in the reader and are interpreted as zeros. On rewritable discs, it is essentially made up of silver, tellurium, indium and antimony. Initially (the disk is completely empty of data...) this surface has a polycrystalline or highly reflective structure. If the software tells the engraver to simulate a pit, then what it will do is increase the temperature of the surface to 600 or 700 °C with the laser, so that the surface now has a non-crystalline structure or low reflectivity. When a land should appear, then the laser power is lowered to leave the polycrystalline structure intact. To erase the disc, the surface is burned at about 200 °C for a long time (from 20 to 40 minutes) making it return to its initial crystalline state. In theory we should be able to erase the surface about 1000 times or so, although with daily wear this mark is never reached.

Engraving by laser action and a magnetic field

The last means of recording a CD is by the action of a laser beam in conjunction with a magnetic field (magneto-optical discs).

Optical discs have the following characteristics, compared to magnetic discs:

Optical discs, in addition to being removable media with the capacity to massively store data in small spaces -at least ten times more than a hard drive of the same size- are portable and secure in data storage (which also remains if power goes out). The fact that they are portable comes from the fact that they are removable from the drive.

Multi-session recording

For some time, computer programs have emerged to burn CDs that allow us to use a CD-R disc as if it were a rewritable disc. This does not mean that the CD can be recorded and later erased, but rather that it can be recorded in different sessions, until it takes up all the available space on the CD. Multisession discs are nothing more than a normal recordable disc, neither in their boxes, nor in the information about their technical details, it is highlighted that it works as a Multisession disc, since this function does not depend on the disc, but rather on how it is recorded.

If a CD is recorded and it is not finalized, we can add a new session to it, wasting a part to separate the sessions (approximately 20 MB). We will make a CD multisession at the moment we make the second recording on it, whether it is finalized or not, however, when recording a music CD the CD-R is automatically finalized and cannot be used as a Multisession disc.

Not all devices or operating systems are capable of recognizing a multi-session disc, or one that is not finalized.

Differences between multi-session CD-R and CD-RW

There can be confusion between a CD-R with multi-session recording and a CD-RW. At the moment when a CD-R disc is made multisession, the software will give it the characteristic that it can be used in multiple sessions, that is, in each recording "sessions" will be created, which will only be modified by what the user see fit. For example, if the files test 1.txt, test 2.txt and test 3.txt have been recorded on a CD-R, a session will have been created on the disc that will be read by all the players and that will contain the mentioned files.. If at any time one of the files is not needed or the content of the recording is modified, the software program will create a new session, after the previous one, where the files that are not to be consulted will not appear, or the modifications will be seen. done, that is, it is possible to add more files, or even remove some that were included. When making a modification, the previous session will not be deleted, but will be hidden by the new session, giving the impression that the files have been deleted or modified, but in reality they remain on the disk. Obviously, the previous sessions, although apparently they do not appear, remain on the disk and are taking up space on it, this means that one day it will no longer be possible to "rewrite" it, modify the files it contains, because the entire capacity of the disk will have been used.. Unlike CD-Rs, CD-RW discs can be erased, or even formatted (it allows the disc to be used, losing part of its capacity, but allowing new files to be recorded on). In the case of using a CD-RW when we erase, we erase it completely, partial erasures can also be done, which need a higher laser power to record again. A CD-RW disc can be used as a USB memory, with appropriate software, as long as the unit supports this feature, files can be manipulated as on a USB memory, with the exception that it is not deleted, but when deleting a file it continues to take up space on the drive, even if you look at it and no such file appears. CD-RW discs need more laser power to be recorded, for this reason rewritable discs have a slower recording speed than recordable discs (they take longer to finish recording). DVD-RW, DVD+RW work similarly, DVD-RAM too, but are designed to be written like USB flash drives (abbreviations that stand for Universal Serial Bus).

Care and preservation of compact discs

Chemical reactions between its components, as well as heat and abuse, can destroy digital data. Therefore, the information must be reviewed periodically to detect failures. To prevent early deterioration of compacts, you just have to treat them well. CD-Rs, based on organic dyes, are more perishable and volatile than compacts and CD-ROMs. You have to verify the backup every 2 years or less. It is advisable to practice making double copies of all data and backing up the information every two years. The following are some recommendations for the acquisition and preservation of recorded and blank compact discs:

- Purchase good quality CD from reliable manufacturers and suppliers. In case of doubt, they can be tested with CD's of various brands and stay with those that have better performance.

- Do not touch the CD with the fingers in the data area, but by the edges or by its printed label.

- Do not expose CDs to dust, excessive heat or long times to direct or artificial sunlight. They must be stored in their respective case and/or package as immediately as possible.

- Do not place stickers on the surface of the CD.

- Do not save CD together of different sizes.

- Store CDs in environments at constant temperature. If they are kept for a long time, they must be kept in a cool and dark environment.

- Avoid storing CDs in very high humidity environments, as mushrooms can be formed in their protective covers.

- In case of quick cleaning to the data face, it should be done from the center of the CD out. Never clean by moving in circles, because wear stripes that can occur have more chances of spoiling the reading process.

- By marking them or writing about them, use a soft-tip marker. Pointed objects can damage the data.

- Do not expose the CDs to water, to falls or to blows.

File systems

The ISO 9660 standard is a standard initially published in 1988 by the ISO, which specifies the format for file storage in compact disc-type supports. The ISO 9660 standard defines a CD-ROM file system. Its purpose is that such means are readable by different operating systems, different suppliers and different platforms, for example, MS-DOS, Microsoft Windows, Mac OS and Unix.

ISO 9660 is a direct descendant of an earlier standardization effort called HSG (groaning) High Sierra Group), which was proposed by a group of industry actors who met in 1985 at the hotel High SierraLake Tahoe, Nevada. Although ISO accepted a large majority of the HSG proposals, there are some minor differences.Contenido relacionado

Portage (software)

MS-DOS

Motorola 68020