Combine harvester

The harvester, combined or mower-thresher is an agricultural machine that mows, threshes and cleans, that is, harvests the products of the main crops. The term combine harvester is generally limited to those that harvest cereals and certain oilseed crops such as soybeans, sunflowers, rapeseed and flax, excluding machines such as the cotton picker or harvester, the sugar cane harvester and those that They harvest vegetables and fruit trees.

History

Since the 19th century there has been an attempt to bring together the reaper and the thresher in a single machine. In 1835 Hiram Moore (1801-1875) and James Hascall built and operated a combine harvester in Michigan, which they patented the following year. It was a 15-foot (4.5 m) cutting width machine, drawn by 20 horses. Moore continued manufacturing combines and even shipped machines to California where they were very successful due to its drier climate. At the end of the 19th century self-propelled or self-propelled machines by steam engines were also built. George Berry manufactured a 22-foot (6.6 m) wide cutting machine in 1887 operated by 6 people. The following year, Berry modified it, extending it to 40 feet (12 m).

In Australia another criterion was followed: instead of cutting the harvest, the ear was separated by removing it using a beater (stripper). In 1843 the Australian farmer John W. Bull (1804-1886) invented a stripper combine that he used in his wheat cultivation. In addition, a prize of £40 had been offered to whoever invented a combine harvester. Bull entered that contest, but the jury rejected his machine. Disillusioned he abandoned the idea, which was taken up by John Ridley (1806-1887) who went on to manufacture strippers. Over the years, the stripper was perfected in Australia. Among the manufacturers, Hugh V. McKay (1865-1929) stood out, becoming the largest manufacturer of agricultural machinery in that country. He even exported strippers to Argentina, where they had a certain popularity. diffusion in the first two decades of the 20th century. These strippers were 5-foot (1.5 m) wide cutting machines drawn by six horses.

In the United States the development of the combine continued. As soon as they became available, internal combustion engines were added to the machines to alleviate the draft of animal power, which was soon replaced by tractors. These trailing machines had 10 to 12 foot (3 to 3.6 m) platforms and could harvest about an acre of wheat in an hour. Little by little, in the 1930s the combine was replacing the harvest with reaper and thresher, especially in extensive agricultural countries such as the United States, Canada, Argentina and Australia. In countries with more intensive agriculture and smaller farms, this change was somewhat later.

The next step was the self-propelled or self-propelled harvester. As it turned out, already at the end of the 19th century Berry had built them in California and in Australia McKay also manufactured automotive stripper from 1924. In Argentina José Fric de Pigue, Province of Buenos Aires, manufactured an automotive harvester (self-propelled) that was tested in December 1918 at the Faculty of Agronomy and Veterinary Medicine from the University of Buenos Aires with favorable results. It had a working width of 9 feet (2.7 m) and a 20 hp engine. In Sunchales, Province of Santa Fe, the Italian immigrant Alfredo Rotania managed to patent a self-propelled harvester in 1929. The machine had a Hercules engine and a Chevrolet differential. With a cutting front of 15 feet (4.5 m), it was capable of harvesting up to 15 hectares per day. Over time, Rotania became an important combine factory.

Major North American agricultural machinery manufacturers began producing self-propelled combines during the 1940s. Instead of being placed on the side, the deck was at the front of the machine, allowing for better maneuverability. In the middle of the century, these combines came equipped with 16-foot cutting platforms (4.8 m) and engines of around 100 HP (0.74 kW), allowing them to harvest 1.2 to 1.5 hectares per hour.. Also at that time, the handling of grains in bags or sacks began to be handled in bulk, which also achieved significant labor savings since the bagger and the bag sewer, who worked on the combine, and the personnel who collected the bags in the stubble.

In Spain, according to Miguel Ángel Rubio Sánchez, the first 100% national harvester was invented from a technical and mechanical point of view by Eleazar Arrieta within the business of Industrias Albajar, S.A. (IASA), in Huesca, in 1958. The mentors of the project from an economic and industrial point of view would be Fernando Albajar and Manuel Albajar. They manufactured 3,554 combine harvesters until the nineties, when IASA closed. The machines were highly recognized for the double cleaning system they implemented.

During the second half of the XX century, the harvester was perfected and its working capacity was expanded. At the beginning of the 21st century, 30-foot (9 m) wheat head machines were common in extensive agricultural countries. of cutting width, a hopper with a capacity of 8,000-10,000 l (6 to 7.5 t) that manages to harvest just over 3 ha/h. They have diesel engines of around 300 HP (220 kW). They come equipped with sensors that report on the instantaneous yield of the crop and grain humidity, as well as the operation of the different mechanisms. A GPS assists and helps the driver in steering the machine. The harvest, which once required countless men for mowing and threshing, can be carried out with these machines with only two operators: the combine driver and the tractor driver who, with hopper cars or carts, receives the grains in bulk and transports them. to deposits.

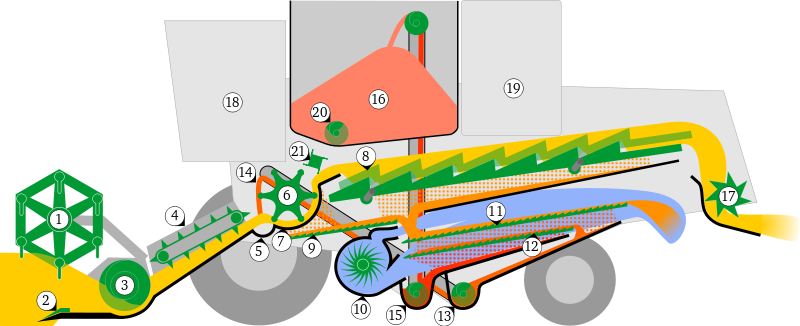

Parts and operation of the combine

The operation of a combine can be seen in the attached diagram. The flow of the harvest first and the chaff later are represented in yellow, the threshed grains with chaff and other impurities in orange and the clean grains in red. The header or platform includes the cutting bar, the reel and the auger that carries the cut crop to the carrier. It is the mowing part of the machine. There are combines in which instead of an auger, tarps (draper) are used. The header is easily detachable from the harvester to facilitate transportation and to exchange it with special headers such as corn or sunflower heads.

Cylinder and concave are the basic mechanisms that perform threshing, and except for the logical improvements that were introduced over time, they are basically similar to those of the thresher. The cylinder is 0.50 to 0.65 m in diameter and 1.20 to 1.70 m wide, and rotates at speeds between 1,000 and 1,200 revolutions per minute for threshing wheat, 500 to 600 in corn, 450 to 850 in soybeans and about 420 in sunflower. The threshed grains fall through the concave. The separation between cylinder and concave is adjustable, depending on the threshed grain and crop conditions. The diagram represents a set of cylinder and transverse concave. In modern machines there is a tendency towards a longitudinal (axial) location that allows progressive threshing; In this case there may be one or two cylinders, with a larger diameter and, above all, longer than conventional ones. The beater fulfills the function of decongesting the cylinder-concave assembly of straw and intercepting the grains fired by the threshing mechanism and forcing them to descend into the concave tray.

The separation of grain and remaining straw is carried out through several mechanisms. The capajas is responsible for separating the grains still retained in the straw by shaking it and finally eliminating the straw through the tail of the machine. At the tail end, a straw spreader is added that distributes the straw more or less uniformly over the ground to facilitate its incorporation into the soil as organic matter and prevent the formation of swathes that can make subsequent work difficult. The concave tray conveys the grains separated by threshing to the screens or sieves. The screen or upper screen performs a first cleaning, separating the grains from the chaff, which is expelled by the tail of the machine along with the straw. The screen or bottom screen completes the cleaning; The grains that do not pass through this sieve due to poor threshing return to the concave cylinder through the return for rethreshing. All this cleaning (purple sector) is helped by an air current generated by the fan that passes through the screens, separating the grains from the light parts and dust. Screen and sieve must be adjusted or exchanged according to the grain harvested. This part of the combine performs the functions that were formerly performed by winnowing and screening.

Finally the clean grains are transported by the grain elevator to the hopper. When it is full, it is unloaded through the unloading auger to cars, trailers or trucks that transport the grains to silos or tanks, or also to bag silos for temporary storage on the property. In order to avoid loss of time due to stoppages of the combine, unloading is generally carried out while the machine is operating.

From his cab the driver has at his disposal not only the usual instruments and controls on a tractor or vehicle, but also a series of controls for the main parts of the combine. Among others, you can start or stop the header as well as regulate its cutting height and the speed and height of the reel, modify the rotation speed of the cylinder and adjust the cylinder-concave separation, regulate the fan, connect and disconnect the auger. discharge, etc. The cabins are closed and generally air-conditioned, protecting the driver from the abundant dust emitted by the combine when working and ensuring a comfortable environment on hot summer days or cold autumn days.

As for the engine the machines can come equipped with engines between 150 and 640 HP (110-470 kW). This wide range has led them to be commercially classified into 10 classes that define their respective benefits. The trend is towards increasingly larger machines and therefore greater work capacity.

As you can see, a combine harvester is a fairly complex machine. Its driver or machinist must be a qualified operator for the task. Knowledge of mechanics is not only necessary to correctly operate and maintain the engine and other mechanisms, but also to regulate the operation of the combine. Poor regulation generates grain losses, which translate into significant economic losses for the producer when they are excessive. It can also cause a loss of quality due to the presence of broken grains, foreign bodies, etc. among the threshed grains.

Harvester work

Once mature, the crops must be harvested without loss of time since any delay can imply economic losses for the farmer. Its main causes in the combine, apart from maintenance tasks and preparation for work, are the following:

- Transfer to and from the harvest place.

- Empty work on the headers of the plot (working on amelgas) when rotating. Usually, the work in the round is more efficient. There may also be work in vacuum at the end of an amelga when a strip is harvested less than the width of the head.

- Download the hopper with the machine stopped. As already said, the download is usually done on the go.

- Wait to download the hopper. Once full, the harvester must stop if you cannot download the hopper. Therefore, before starting your work, it is necessary to foresee the transport of the grains harvested to the silos or barns. In that regard, the harvester and the car or truck that receives the grains are two inseparable elements in every harvest that should be programmed together. Logistics is an important part, especially when several harvesters operate simultaneously in the same field.

- Fuel load and maintenance. The harvesters usually have enough fuel tanks for a whole working day. Nor do they need maintenance during the working day.

- Machine regulations. While many regulations can be done by the driver from your cabin, some need detentions. One of them is to perform good control of grain losses, an important aspect due to their potential economic damages.

- Machine jams. They are usually given when the feeding of the cylinder-concave set exceeds its trilla capacity. It can also be stuck in the head caused by excessive harvester speed and other parts of the machine.

- Hails. He's never exempt from unexpected breakdowns. When breakdowns are repeated, they are an indicator of poor preventive maintenance.

- Staff breaks or rest. Harvest days can be extended. It is advisable to harvest with two operators that can be alternated in the driving of the machine, or a person who transitorily can drive it while the driver pauses.

As a general guideline and although highly variable, time losses can be quantified at around 15-25% of the combine's operating time. In other words, 75-85% of operational time is effective working time.

The combines usually work during the day, although they are equipped with lights that allow them to do so without problems at night. However, in humid regions night work is limited by the presence of dew. When it begins to form, it moistens the grain, which prevents the harvest from continuing since the grain must be stored without excess moisture. For the same reason, daily work only begins in the mornings once the dew has disappeared.

If the grain is harvested with a humidity higher than that permissible for safe storage, it must be dried. This operation is carried out in silo plants with grain dryers, prior to storage. Drying adds costs to the farmer, but it is often preferred to harvest the grain while wet to avoid losses caused by harvest delays.

In the old way of harvesting with mowing, sheaving, tying and threshing, while the sheaves remained in the stubble there was a natural drying of the grain, and even its maturation was completed. This allowed more time available to carry out these tasks than with the combine. Only the harvester gave rise to the need for artificial drying of the grains and with this it was necessary to have grain dryers.

Types of combines

The corn and sunflower harvesters are the same as those used for harvesting fine grains. It is only necessary to place the specific header for each of these crops and make the regulations specific to each crop, such as cylinder speed, cylinder-concave separation, appropriate screens, etc.

Rice harvesters are characterized by using dual wheels or track systems to be able to work without problems on the soft soils of rice fields.

Slope harvesters are machines specially adapted to harvest on steeply sloping soils. They have a hydraulic mechanism that keeps the body of the combine horizontal since the concave cylinder, straw removers and sieves need to be level to work properly, as does the engine. On the other hand, the head and wheels adapt to the slope.

"Use of the combine"

The combines increased their work capacity over time in order to reduce the duration of the harvest. Given the surface area of a crop, the greater the work capacity of the machine, the less its annual use. The combine is characterized precisely by being a machine that works relatively few hours per year, due to the short harvest times. It is estimated that in the United States the annual use of combine harvesters is between 300 and 500 h/year and in Argentina between 900 and 1300.

Increasingly larger machines mean increasing capital investment for farmers, which small producers generally cannot afford. A high investment results in a high fixed cost. This has favored the emergence of the harvest contractor, that is, the owner of a harvester who provides his services to third parties. In this way, by increasing the annual use of the machine, it manages to dilute the fixed costs over a larger surface area. This is also helped by the fact that the same machine can harvest both winter crops at the end of spring (wheat, barley, rapeseed, etc.), and summer crops harvested in autumn (soybeans, corn, etc.), without modifications or just changing the head and other minor parts. In countries with a large north-south extension such as Argentina, contractors can also take advantage of the fact that the wheat harvest begins in October in the north of the country and ends in early January in the south of the Pampas region. If you add to that the soybean harvest that begins in April and ends in June with late soybeans, you can achieve high annual uses of your machine. For this reason, in Argentina it is estimated that 90% of the grains harvested are harvested by contractors. In Europe, the area harvested by contractors differs significantly between countries: in Italy it is 85%, followed by Belgium with 75%, Germany 50%, France 35%, Ireland 30% and Denmark and Holland with 20% each.

Contenido relacionado

Irrigation techniques

Sprayer

Precision farming

PHP nuke

DirectX