Brick

A brick is a construction material, normally ceramic and with an orthohedral shape, whose more normal dimensions allow an operator to place it with one hand. Bricks are used in construction in general. These can be positioned in different patterns, collectively known as rigs. Various types of mortars are used to hold bricks together and form a durable structure.

History

Bricks have been used as a building element for about 11,000 years. They are already documented in the activity of farmers in the pre-ceramic Neolithic of the Mediterranean Levant around 9500 BC. C. in the form of adobe, since in the areas where they built their cities, wood and stone hardly existed. The Sumerians and Babylonians dried their adobe bricks in the sun; However, to reinforce their walls and ramparts, on the external parts, they covered them with baked clay bricks, which are more resistant to the elements. Sometimes they also covered them with enamels to achieve decorative effects. Its diffusion in the Mediterranean area occurred with the expansion of the Roman Empire. The dimensions were changing over time.

The brick work had dimensions determined by the size of the pieces. The longest length (the rope) of the brick was generally one foot, which obviously depended on the dimension of that measure in the area where it was manufactured, and for this reason the factories built with them were called, like one foot, half a foot, etc., according to its width; when later the relationship with the traditional measure of the foot was lost, they wanted to call the half-foot brick wall, as zither as well as staple, staple and half or two horns the old foot, foot and a half, two feet, but these names are not widely used.

Brick as a constructive element

Clay

The clay with which the brick is made is a sedimentary material of very small particles of hydrated alumina silicates, as well as other minerals such as kaolin, montmorillonite and illite. Adobe is considered the precursor of brick, since it is based on the concept of using clayey mud to build walls, although adobe does not undergo the physical-chemical changes of firing. Brick is the irreversible version of adobe, the product of firing at high temperatures (more than 350 °C).

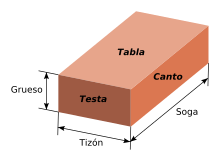

Geometry

Its shape is that of a rectangular parallelepiped, in which its different dimensions are called rope, tizón and thickness, being the rope its greatest dimension. Likewise, the different faces of the brick are called table, edge and testa (the table is the largest). In general, the rope is twice the length of the brand or, more precisely, two brands plus a joint, which allows them to be freely combined. The thick, on the other hand, may not be modulated.

There are different formats of bricks, they are generally of a size that allows them to be handled with one hand. In particular, they highlight the metric format, in which the dimensions are 24 × 11.5 × 5.25 / 7 / 3.5 cm (each dimension is twice the immediately smaller, plus 1 cm de junta) and the Catalan format measuring 29 × 14 × 5.2 / 7.5 / 6 cm, and the more standard ones that measure 25 × 12 × 5 cm.

Due to their great demand, given their low cost of work, they continue to use measurements of 50 x 24 x 5 cm, especially in hollow brick formats.

Types of brick

According to their shape, bricks are classified as:

- Tejar or manual brick, simulate the old handmade bricks, with rough appearance and rough faces. They have good ornamental properties.

- Solid brick, those with less than 10% drilling in the table. Some models have clippings in these tables and in the testaments for the execution of walls without sores.

- Drilled brick (or cough), which are all those who have holes in the table that occupy more than 10% of the surface of it. They are used in the execution of brick facades.

- Hollow brick, are those who possess perforations in the chant or testa that reduce the weight and volume of the material used in them, facilitating their cutting and handling. Those who possess horizontal holes are used for partition that will not bear large loads. They can be of several types:

- Rasilla: your rope and tizón are much greater than your thick. In Spain, its most common dimensions were 24 × 11.5 × 2.5 cm. (now rarely made of this format)

- Simple hollow brick: has a row of perforations in the testa. Dimensions 24 × 11.5 × 4 cm.

- Double hollow brick: with two rows of perforations in the testa.

- Triple hollow: It has three rows of perforations in the testa.

- Flattened brick, the one who has a curved profile, so that by placing a brick frost, usually to sardinel, they make up a cumshot moulding. The name comes from the templates used by the canteros to tear the stones, and they are used to give the above form to the brick.

- Caravista brick: are those used outdoors with a special finish.

- Refractory brick: it is placed in places where it should withstand high temperatures, such as ovens or fireplaces.

Historical typology

- "Later" or traditional Roman brick, made of adobe or terracotta.

- Tile brick, usually of 28 × 14 cm and little thickness, and glazed by one of its faces;

- Nasrid brick of 29 × 14 x 4 cm; also known as Egyptian or lidium brick, related to the Spanish almohade module brick;

- Visigod brick, patterned brick variety;

- Columnaric brick (the Roman column) in the form of a circular sector to form columns;

- Fine brick of Andalusian folk pottery, traditional tile variety, of purified and polished paste by one of its faces and edges, usually 28 × 14 x 2.3 cm.;

- Ladrillo mahón, traditional in Catalonia, of 29 × 14 x 4 cm;

- Dutch brick, subjected to prolonged and half-vitrify cooking.

Uses

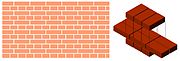

Bricks are used in construction for enclosures, facades and partitions. It is mainly used to build walls or partitions. Although they can be placed in the bone, it is common for them to be received with mortar. The arrangement of the bricks in the wall is known as the rig, and there is a great variety of them.

Rigs

Arejo is the law of blocking or disposition of the bricks in a wall, which stipulates from the dimensions of the wall to the encounters and the enjarjes, so that the wall rises homogeneously throughout the height of the building. Some types of rigs are as follows:

- She's wearing ropes.: the sides of the wall are formed by the ropes of the brick, has a thickness of half foot (the tizón) and is very used for facades of face brick.

- I'm ready for you. or the Spanish: in this case the tizones form the sides of the wall and its thickness is 1 foot (the rope). Very used in walls that support structural loads (bearers) that can have between 12.5 cm and 24 cm placed on medium asta or rope.

- Came to sardinel: prepared by pieces arranged for sardinel, that is, of singing, so that the tizones are seen.

- English: in this case they alternate brick to rope and tizón, blocking the rim to brick, giving a thickness of 1 foot (the rope). It is used much for supporting walls in facades of face brick. His work is better than the wall at tizones, but his work is more complicated and requires more experienced labor.

- He's ready for bakery.: is the employee for the execution of partitions, its thickness is the thickness of the piece and is not prepared to absorb loads except its own weight.

- Sticker.: it's like the pairing on a roll but leaving holes between the horizontal pieces. It is used in those interim partitions that should let the room ventilate and in a certain type of roof structure.

Requirements for brick laying:

- Place them perfectly soaked (if not the brick absorbs the water of the mortar that will not break as it should).

- Place them by pressing them to ensure proper adherence to the mortar.

- Horizontal and aligned yarns.

- Vertical joints (sores) will be alternated without continuity with a thickness of between 1 and 1,5 cm.

- The walls that cross or wall together must be perfectly locked.

- The "plome" and "level" of the frosts will be controlled.

- The use of nails, wires, or irons is not permitted for wall or outwork.

- The walls will be attached to the structures by auxiliary armor (iron 6 mm in diameter).

Reinforced ceramics

Brick can also be used by placing it with steel reinforcement at the junction of the rows, which allows large, light and economical structures. The technique was developed by the Uruguayan engineer Eladio Dieste.

Brick making

Elaboration process

Currently, in the manufacture of bricks, a series of standardized processes are carried out, ranging from the choice of clay material to the final packaging process. The raw material used for the production of bricks is, fundamentally, clay. This material is composed, essentially and in variable amounts, of iron oxides and other alkaline materials, such as calcium oxides and magnesium oxides.

The particles of the material are capable of hygroscopically absorbing up to 70% of their weight in water. When it is hydrated, the clay becomes plastic enough to be molded, unlike when it is dry; state in which it presents an earthy aspect.

During the hardening phase, by drying or firing, the clayey material acquires characteristics of notable solidity, and experiences a decrease in mass, due to loss of water, of between 5 and 15%.

Once the type of clay is selected, the process can be summarized as:

- Madura

- Mechanical treatment

- Processed raw material deposit

- Humidification

- Molde

- Drying

- Cooking

- Storage

Maturation

Before incorporating the clay into the production cycle, it must be subjected to certain crushing, homogenization and resting treatments in the open air, to obtain an adequate consistency, tangent drying and uniformity of the desired physical and chemical characteristics.

The purpose of resting outdoors is to facilitate the crumbling of the clods and the dissolution of the nodules to prevent the agglomerations of clayey particles. Exposure to atmospheric action (air, rain, sun, ice, etc.) also favors the decomposition of organic matter that may be present and allows the chemical and biological purification of the material. In this way, a completely inert material is obtained and little given to subsequent mechanical or chemical transformations.

Prebrew

After maturation, which takes place in the storage area, follows the pre-processing phase, which consists of a series of operations that have the purpose of purifying and refining the raw material. The instruments used in the pre-processing, for a purely mechanical treatment are usually:

- Breakers: as its own name indicates, it serves to reduce the dimensions of the ferrets to a diameter of between 15 and 30 mm.

- Stone remover: it is usually made up of two cylinders that rotate at different speeds, able to separate the clay from the stones or "chinos".

- Disintegration: it is responsible for crushing the larger, harder and compact terrestrials by the action of a series of dentured cylinders.

- Refining laminator: consists of two smooth rotary cylinders mounted on parallel axes, with separation, between itself, from 1 to 2 mm, space through which the clay is passed by subjecting it to a crush and an ironing that makes the particles even smaller. In this last phase we achieve the eventual crushing of the last nodules that could still be inside the material.

Depot of processed raw material

The pre-processing phase is followed by the deposit of material in special silos in a covered area, where the material is definitively homogenized both in appearance and in physical-chemical characteristics.

Humidification

Before reaching the molding operation, the clay is removed from the silos and taken to a refining rolling mill, and later to a dampening mixer, where water is added to obtain the precise humidity.

Moulding

Moulding consists of passing the clay mixture through a nozzle at the end of the structure (extrusion). The nozzle is a perforated plate that has the shape of the object to be produced.

Moulding is usually done hot using saturated steam at approximately 130°C and at reduced pressure. Proceeding in this way, a more uniform humidity and a more compact mass are obtained, since steam has a greater penetrating power than water.

Drying

Drying is one of the most delicate phases of the production process. The good result and quality of the material depends, to a large extent, on this stage, more than anything with regard to the absence of cracks. The purpose of drying is to eliminate the water added in the molding phase in order to move on to the firing phase.

This phase is carried out in dryers that can be of different types. Sometimes air is circulated from one end to the other inside the dryer, and other times it is the material that circulates inside the dryer without inducing air currents. The most normal thing is that the elimination of water from the raw material is carried out by blowing hot air with a variable amount of humidity. This makes it possible to avoid thermohygrometric shocks that can produce a decrease in the mass of water at different rates in different areas of the material and, therefore, produce localized cracks.

Cooking

It is carried out in tunnel kilns, which in some cases can measure up to 120 m in length, and where the temperature of the firing zone ranges between 900 °C and 1000 °C.

Inside the oven the temperature varies continuously and uniformly. The dried material is placed on special trolleys, in standard packages, and is introduced through one end of the tunnel, exiting through the opposite end once it is cooked.

Sintering occurs during firing, so firing is one of the crucial phases of the process as regards the strength of the brick.

Storage

Before packaging, packages are formed on pallets, which will later allow them to be easily moved with forklift trucks. The packaging process consists of wrapping the packages with plastic or metal straps, so that they can be deposited in storage places until they are taken to the construction site.