Absorption refrigeration

The absorption refrigeration system is a means of producing cold that, as in the compression refrigeration system, takes advantage of the fact that substances absorb heat when they change state, from liquid to gaseous. Just as in the compression system the cycle is done by a compressor, in the case of absorption, the cycle is physically based on the ability of some substances, such as lithium bromide, to absorb another substance, such as water., in the vapor phase. Another possibility is to use water as the absorbing substance (solvent) and ammonia as the absorbed substance (solute).

The technique was born in 1859, when Ferdinand Carré managed to make ice with the first ammonia-water cycle absorption machine.

Operation

The pair of working fluids normally used is water-lithium bromide, because they allow for greater efficiency. Lithium bromide is used because it has a great capacity to absorb water and because it can be dehydrated by heat.

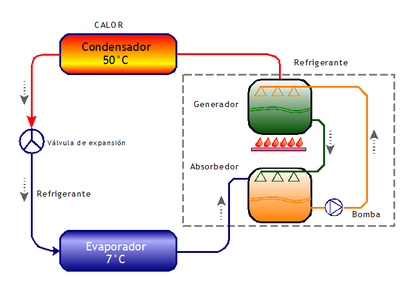

The operation of the absorption refrigeration cycle is as follows. The water (refrigerant), which moves through a circuit at low pressure, evaporates in a heat exchanger, called an evaporator. Evaporation needs heat, which is obtained from an exchanger in which a secondary fluid (usually also water) is cooled, which is carried through a network of pipes to cool the rooms or chambers of interest. After the evaporator, the lithium bromide absorbs the water vapor in the absorber, producing a dilute or weak solution of bromide in water. This solution passes to the generator, where the solvent and solute are separated by heat from an external source; The water goes to the condenser, which is another exchanger where it gives up most of the heat received in the generator, and from there it goes back to the evaporator, through the valve of expansion; the bromide, now as a concentrated solution in water, returns to the absorber to close the cycle. In short, in the absorber heat is released when the gas is absorbed, while in the generator heat is absorbed when the gas is released.

Although it does not appear in the figure, a heat exchanger is also usually used, putting the absorber-generator and generator-absorber ducts in contact, without mixing, to preheat the lithium bromide-water solution, before passing to the heater (generator), while, in turn, the concentrated lithium bromide solution cools down when it goes to the absorber, since absorption is better done at low temperature. In fact, in the absorber there must be an exchanger to cool it with the cooling tower.

As in the compression refrigeration cycle, the system requires a cooling tower to dissipate excess heat (sum of that provided by the external source and that extracted from the premises or refrigerated spaces). The heat transfer fluid that goes to the tower circulates successively through two exchangers located in the absorber and in the condenser.

As can be seen in the diagram, the only mechanical elements in the cycle are a pump that takes the concentrated solution to the generator and another, not shown, to take the heat transfer unit to the cooling.

The ammonia-water cycle is similar, except that in this case the refrigerant is ammonia and the absorbent is water. It is used, although it is less energy efficient, because it has the advantage of being able to reach temperatures below 0 °C, that is, in appliances for freezing, such as refrigerators.

Advantages and disadvantages

The performance, measured by the COP (coefficient of performance, in Spanish regulations, by the CoDeRE, Coefficient of Energy Performance), is lower than in the compression method (between 0.8 and 1.2 versus 3 and 5.5). Although, it is true that the COP obtained by compression takes into account the electrical energy invested in the compressor, which is not primary energy itself. On the other hand, in an absorption system, the energy used to calculate the COP is the heat supplied to the generator, which is an evaluable primary energy. Therefore, the compression and absorption COP cannot be compared (it is better and more useful to compare them through the second principle of thermodynamics, to assess the quality of the energy used).

An example of this situation could be a solar cooling installation (summer air conditioning): if photovoltaic panels were used, only 15-20% of electricity could be used compared to thermal solar panels that could use up to 90% of the solar energy received, and at a much lower installation price.

The complete set of solar panels-absorption would have a COP of between 0.72 and 1.08 and the compression between 0.54 (18% panels and COP of 3, very common) and 1.1 (20% panels and COP of 5.5)

If electrical energy from the network is used, for the compression system, when it reaches the socket it does so with a performance of less than 25% of the primary energy used to generate it, which greatly reduces the differences performance (0.8 vs. 1.37). Despite this, in certain cases, when the energy comes from an inexpensive heat source, even waste or a by-product destined for disposal, it is widely worth using an absorption system. This is the case of using the system in a trigeneration cycle: electricity is produced with a thermal system and the residual heat (around 50% of the primary energy used) is used for the cooling system.

To the heat supplied to the refrigeration process is added the heat removed from the cooled area. So the applied heat can be reused. However, the residual heat is at a lower temperature (despite the amount of heat being greater), so its applications are scarce.

Absorption generating devices are more bulky and require immobility (which does not allow their use in automobiles, which would be very convenient as an energy saver since the engine has large surpluses of thermal energy, dissipated in the radiator).

Other forms of use are through cogeneration (in this case, rather, trigeneration), that is, the use of residual heat from thermoelectric power plants, that is, free energy.

Contenido relacionado

Lucy

(116) Sirona

Micrometer